Medeek Wall Plugin

-

Technical discussion about groups vs. components here:

Group Name or Description

I’ve been in the habit of setting both the name and description for a group but really only ohe of these parameters is being displayed as the Instance name in the Entity Info tray. So where or how is the description fie…

SketchUp Community (forums.sketchup.com)

This is related to the way I am handling certain elements such as studs, blocking, insulation and other arrayed building elements.

-

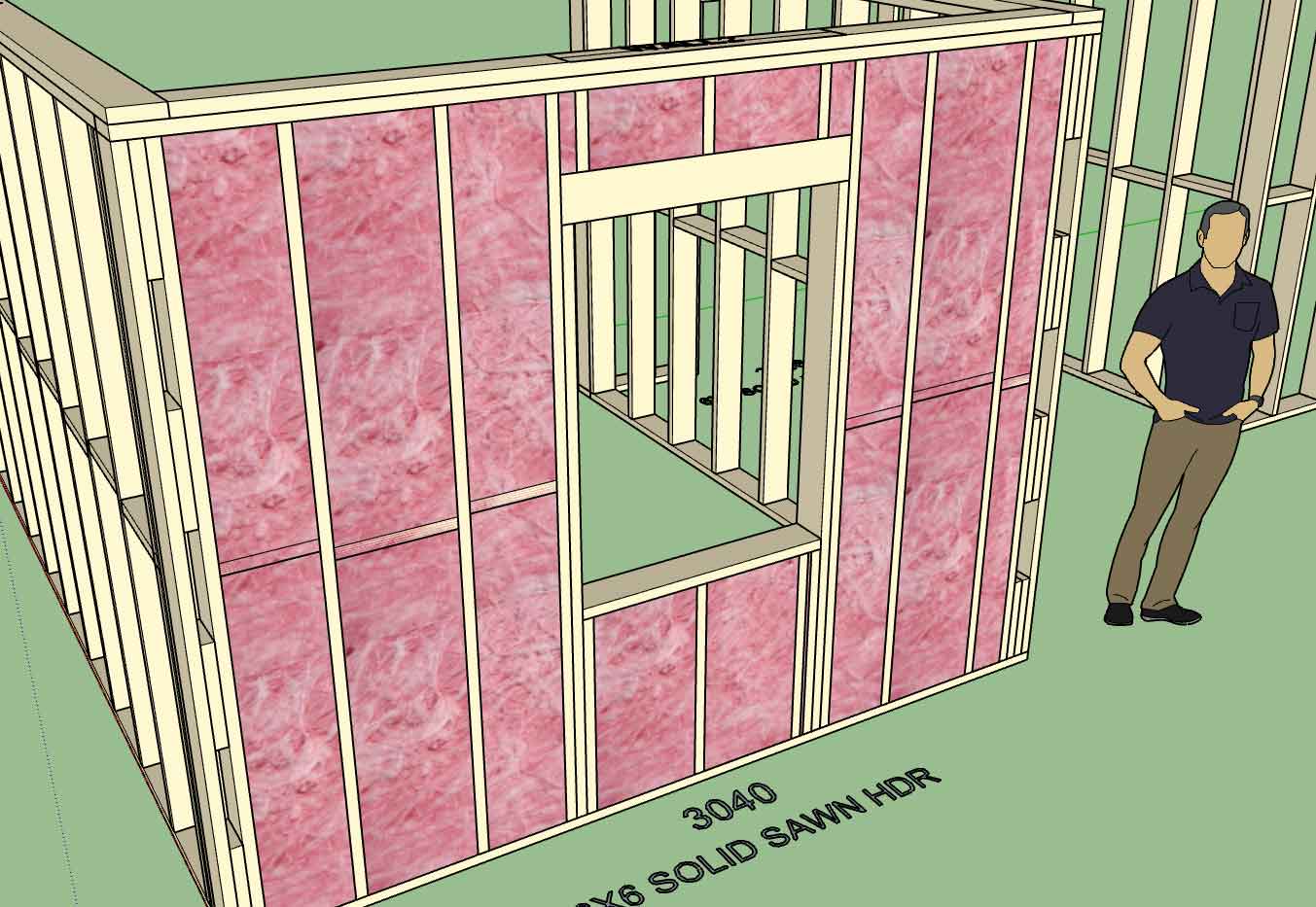

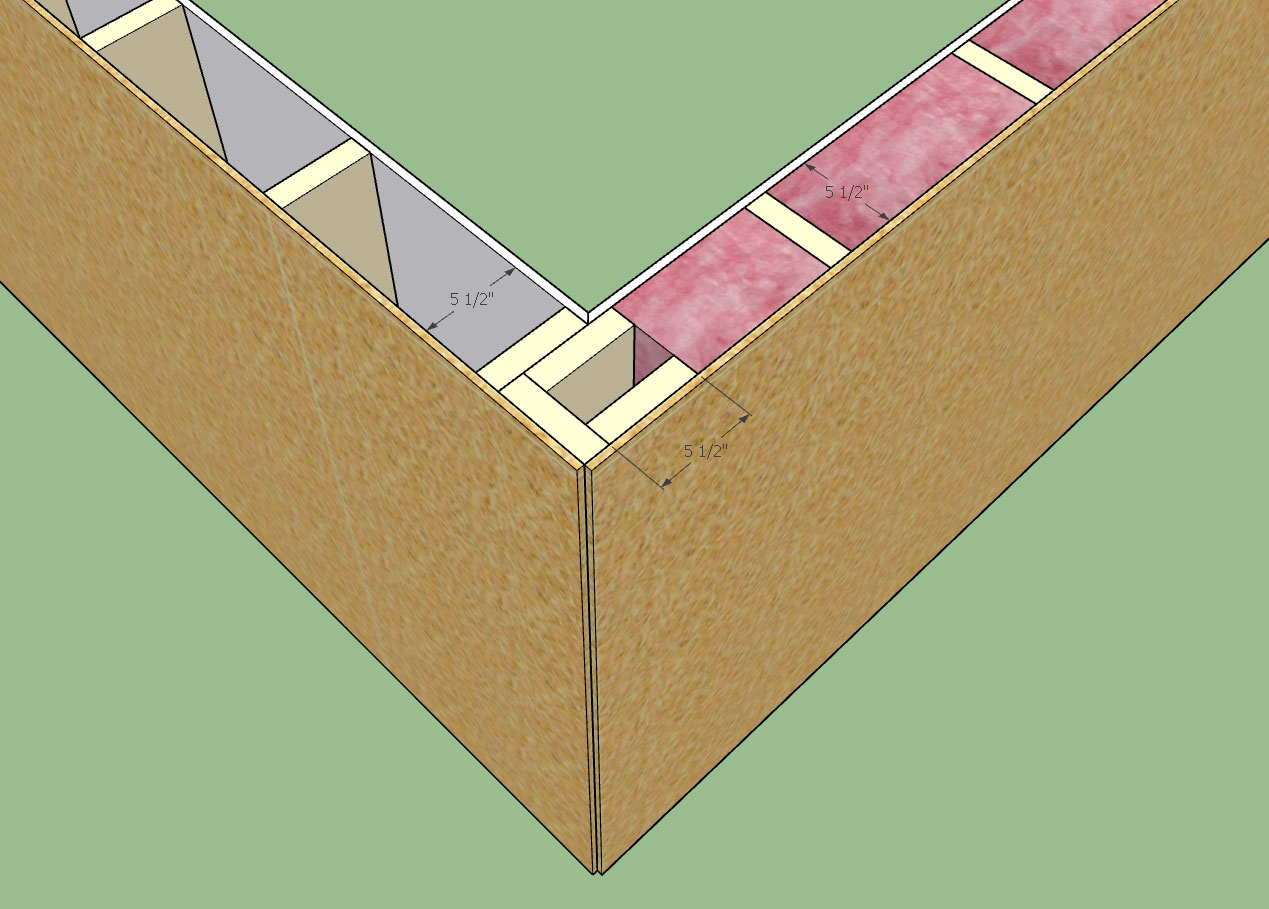

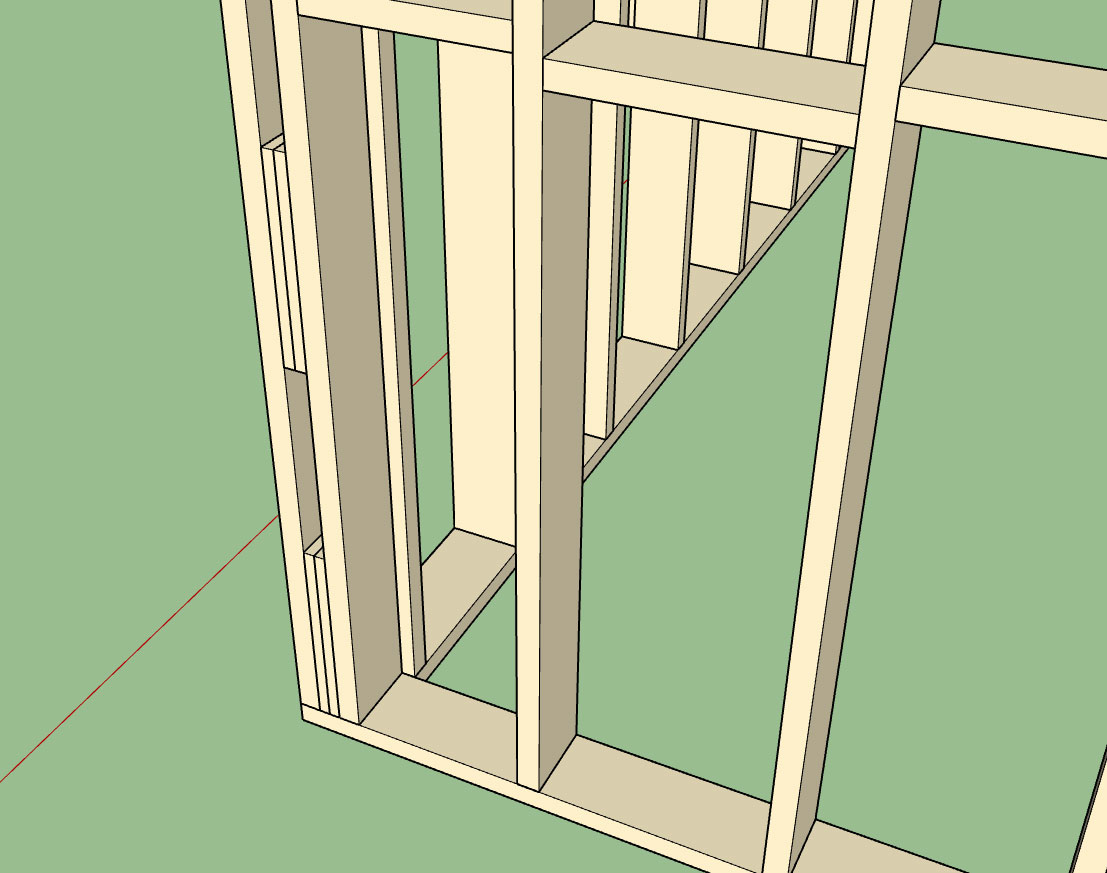

Currently in the plugin I have only implemented the California Corner (as we Americans call it) or Energy Corner for corner treatment however there are number of ways to handle corners.

https://design.medeek.com/resources/framing/FRAMING_CORNERS.pdf

I have been requested by a potential client to enable the following corner type: "Solid corner with short blocks". For a deeper wall sometimes two rows of blocks are used (2x6 wall) rather than one.

I can implement the solid corner however I need some more information:

1.) If you use blocking rather than a full stud how do you determine the length of the blocks and the number of blocks in a given wall height? Is there any rule of thumb with this? I just need to come up with a reasonable algorithm.

2.) Is the blocking typically the same dimensional lumber as the studs?

-

For wall corners I will be adding in the following additional corner treatments:

- 3 Stud Solid

- 4 Stud Solid

- 3 Stud Block

- 4 Stud Block

When the user sets the number of studs for the corner on anything other than one, that setting will override the corner treatment for the above corner treatment types. However this is not the case for the California corner (however I may change it in the future if it makes sense to).

These algorithm can get a bit complicated due to the number of permutations possible when you start mixing up corner treatments and multi-stud corners for shearwalls.

The problem I find with California Corners is that it does not provide very good backing for ext. outside corners when it comes to siding and trim. However it certainly is better for insulation and much easier on the electricians.

There does not seem to be any hard and fast rule on the length of blocks used but it seems to average between 12" to 14", so I will set my algorithm to a max. block length of 14" . So for example a 96" wall will have four blocks at 13.714".

-

Version 0.9.9j - 11.13.2018

- Added the following corner treatments: 3 Stud Solid, 4 Stud Solid, 3 Stud Block, 4 Stud Block, U-Cal

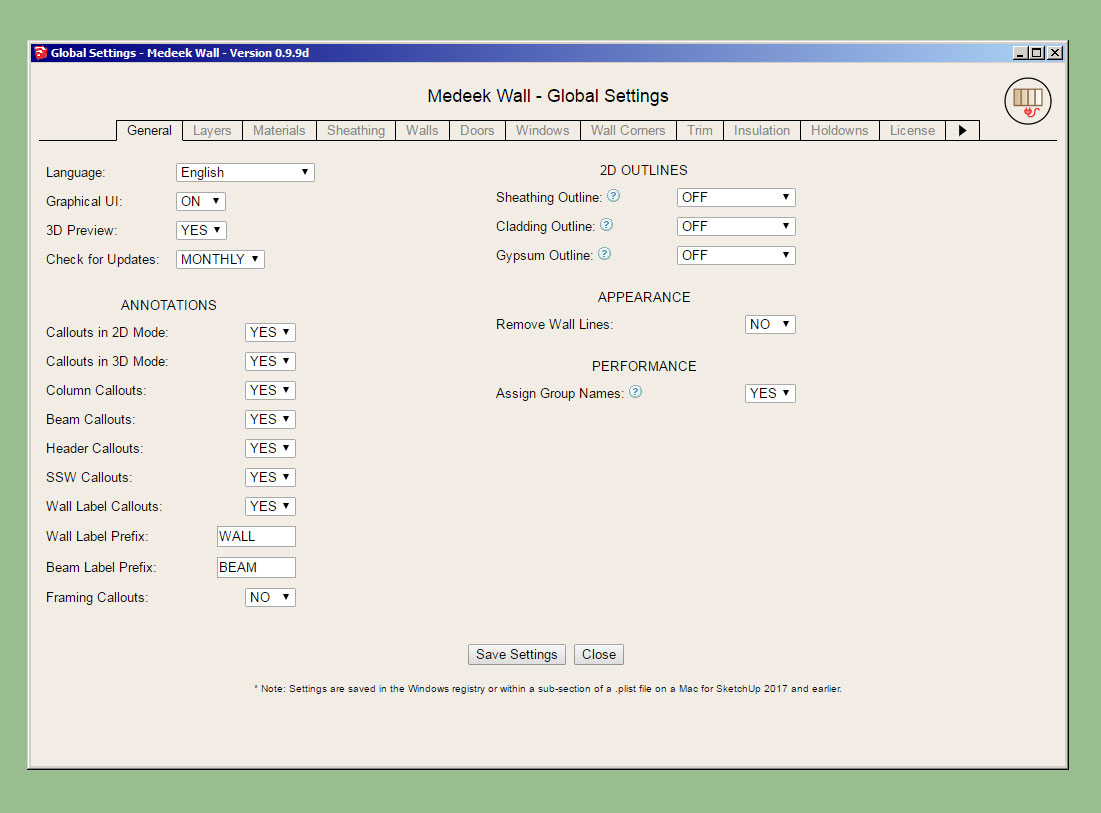

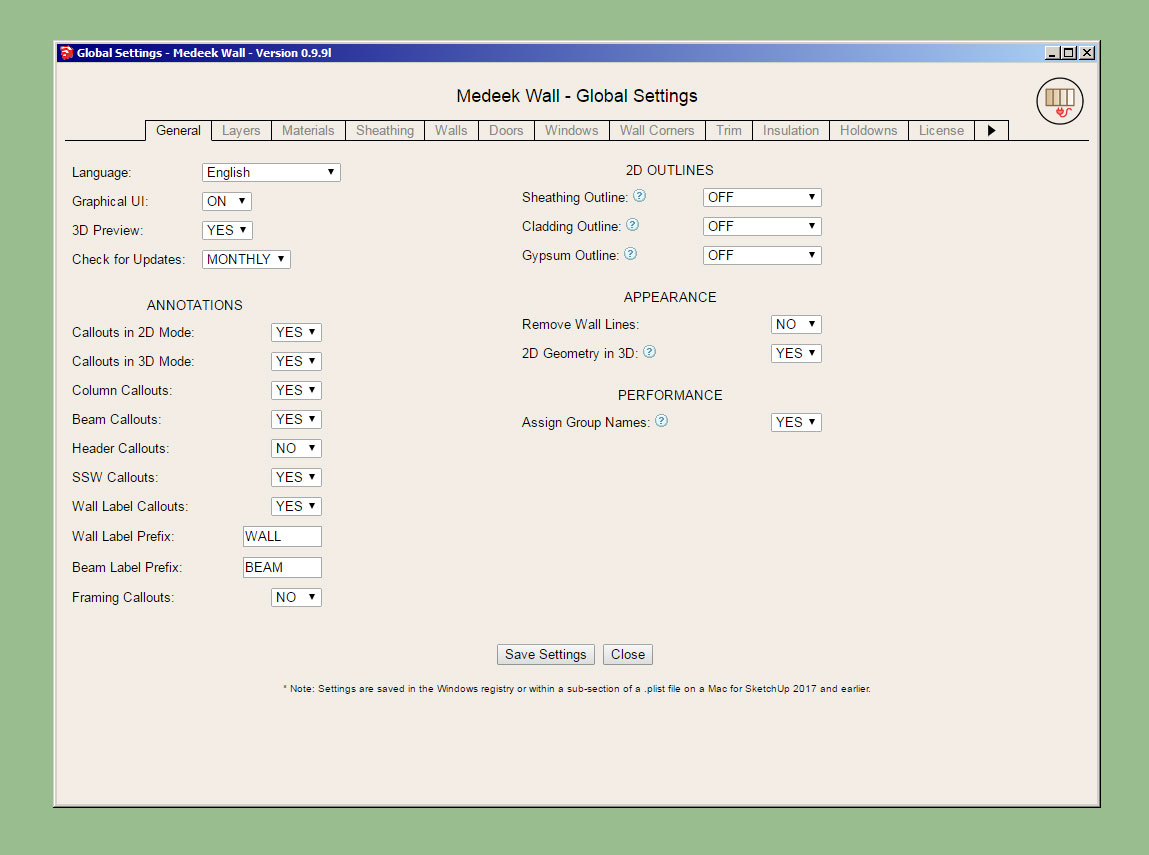

- Enabled a parameter in the General tab of the global settings to toggle the labeling of groups.

I also addressed some minor issues with the way blocking and insulation interact with the corner treatments. Its seems I have that ironed out now and much less likely to generate geometry that clashes.

I don't know how commonly the U-shape California Corner (U-Cal) is used (shown above) but I really like the fact that it offers more nailing surface for ext. trim and siding. I've had a few requests for it as well, so being as it was not too hard to include I added it in. There are now seven possible corner treatments for walls, the other two are California or None.

I typically like to name all of the groups I create within the assemblies however there may be some who do not want this behaviour and so I have made it optional.

-

Version 0.9.9k - 11.15.2018

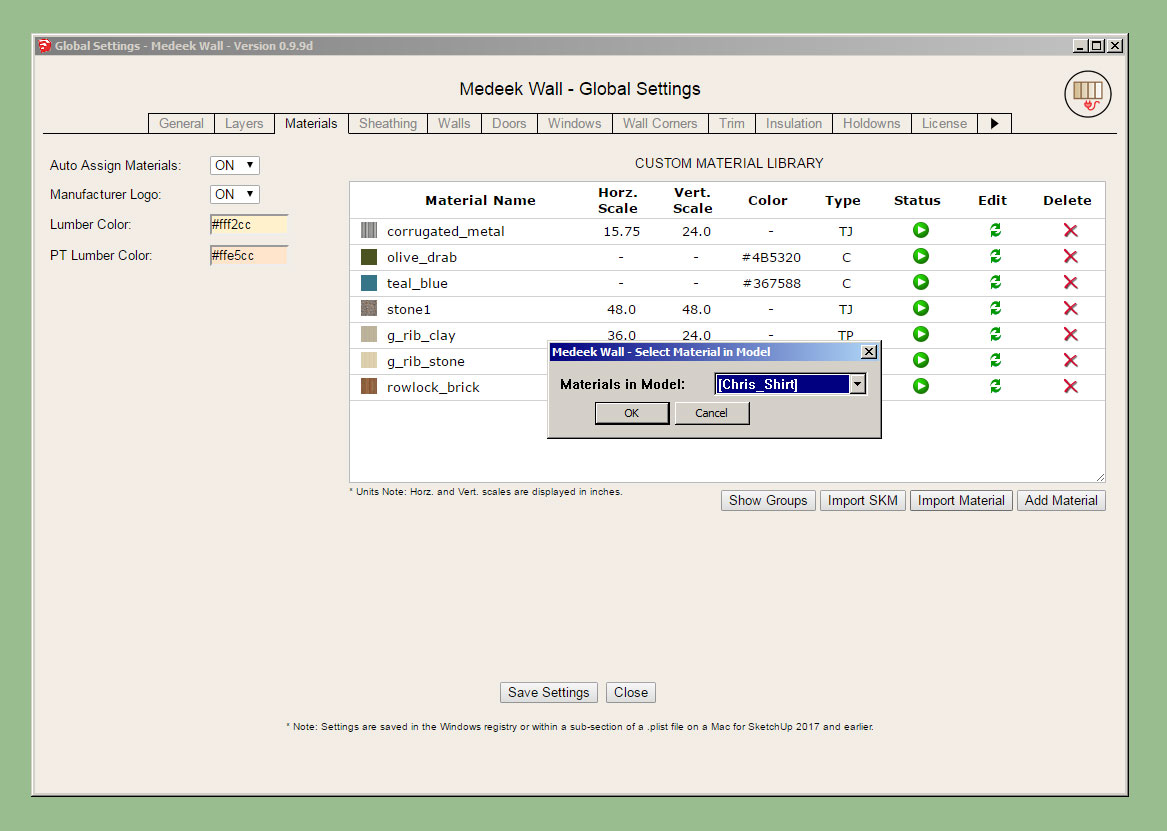

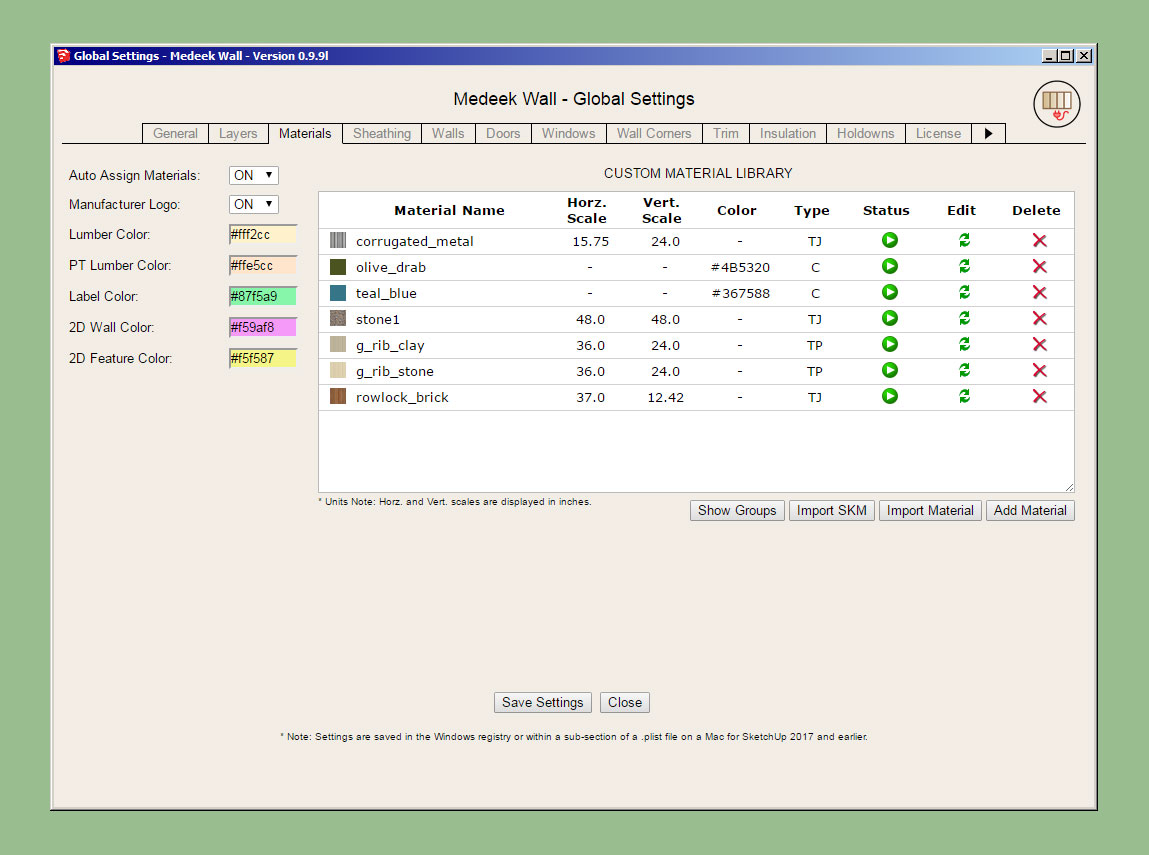

- Added the ability to import materials directly from the model within the Custom Material Libary/Manager in the global settings.

- Provided an additional parameter in the Wall Corners tab of the global settings for setting the thickness of corner blocking (3 and 4 Stud Block corner treatment only).

With this latest update the tutorial on the Material Manager is somewhat out-of-date/obsolete. However the basic functionality has not changed, I've really only added one additional action.

The ability to customize the blocking on these corner treatments was per a request from one of our Australian clients. I've added a tooltip in the global settings to more fully explain the usage of this parameter.

Now back to the big items on the list.

-

Some of you may have noticed the difference in the way materials are handled between the garage doors and man doors. The method being used in the garage door module is the new and improved method. I will be updating both the man door module and the window module to this new system which incorporates the materials in the Custom Material Library.

Also at some point I need to switch the draw door, draw window and draw garage door menus to HTML. As always, never a dull moment and way too much to do.

-

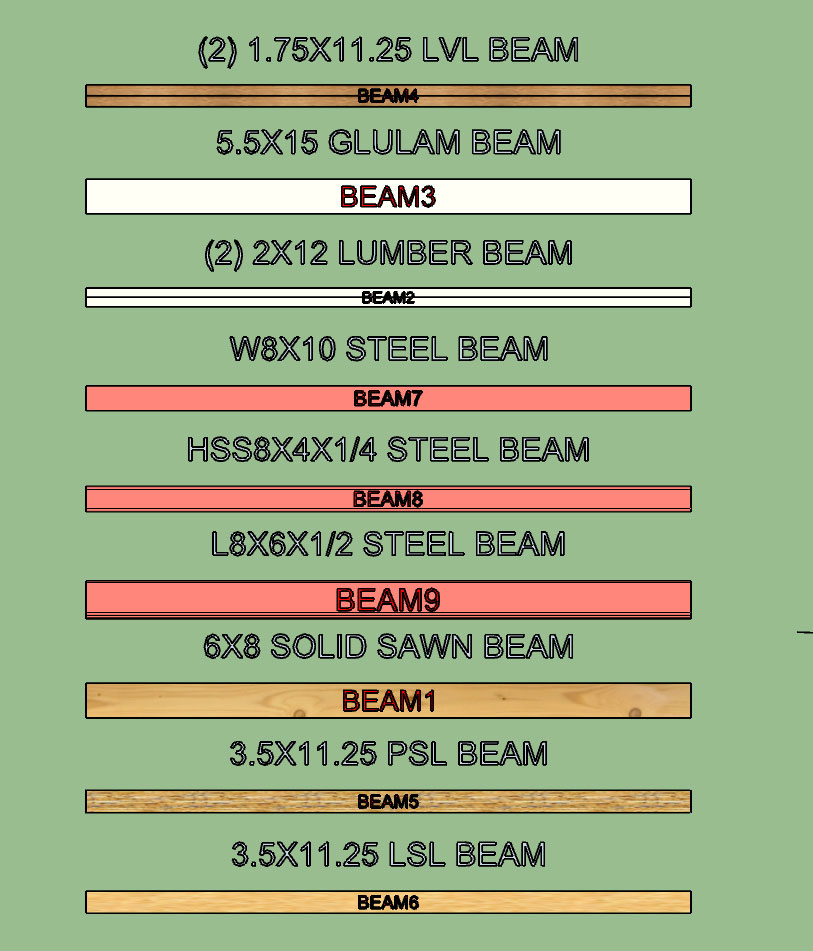

Per customer request the available sizes of Wide Flange Steel Beams will be increased to the following:

W8x10

W8x13

W8x15

W8x18

W8x21W10x12

W10x15

W10x17

W10x19W12x14

W12x16

W12x19

W12x22W14x22

W14x26

W14x30

W14x34W16x26

W16x31

W16x36

W16x40W18x35

W18x40

W18x46

W18x50W21x44

W21x50

W21x57

W21x62W24x55

W24x62

W24x68

W24x76 -

Version 0.9.9i - 11.10.2018

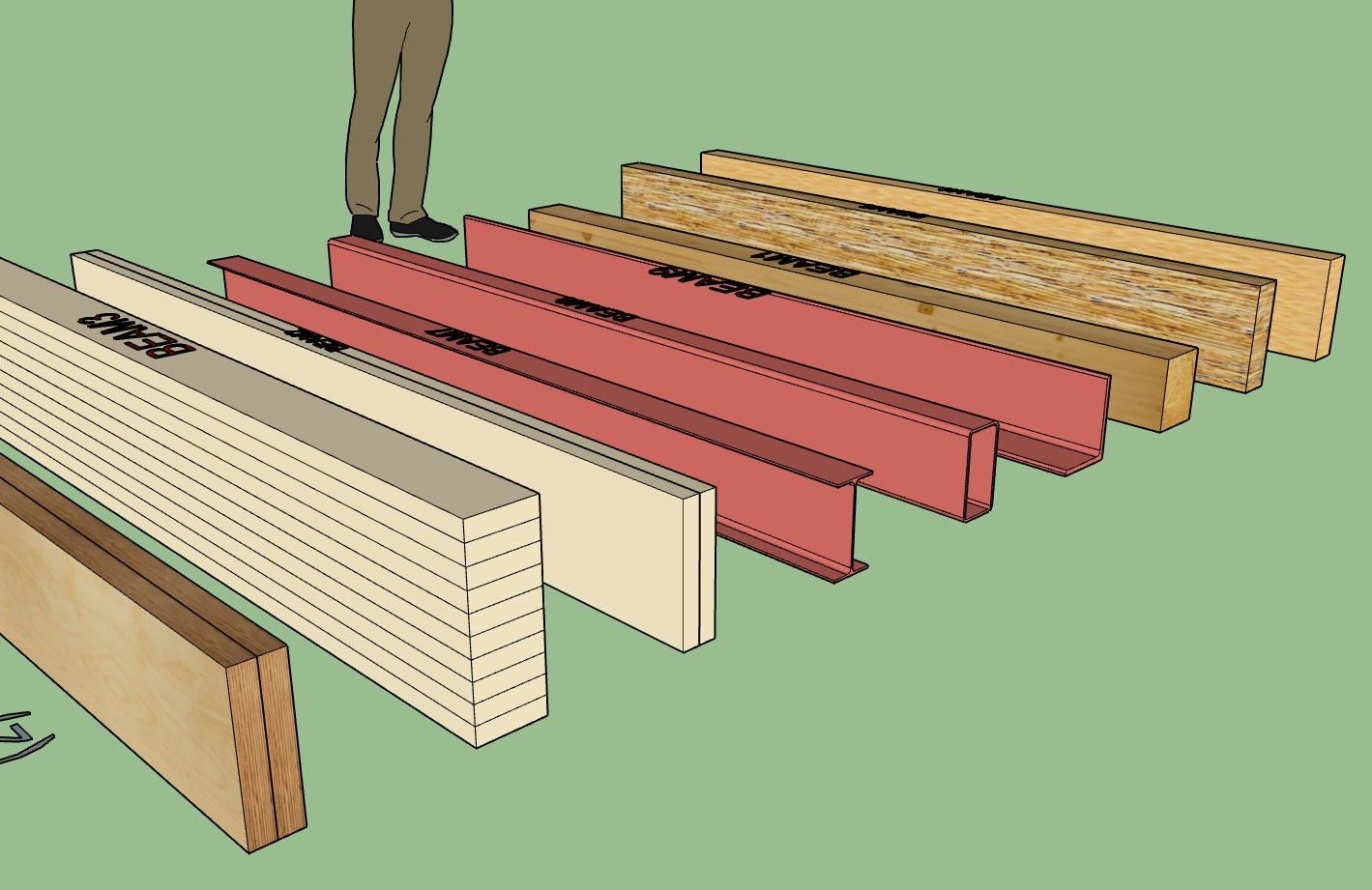

- Added angle iron (L) beams to the beam module.

- Added fillet radiuses to wide flange (W) and universal (UB) beams.

Nine different beam types with two series of wide flange beams (W and UB).

Aside from residential structures one could also use the beam module to create various structural steel assemblies, however that is not really the purpose or target audience for this module.

I added the fillets to the wide flange profiles per customer requests. The primary reason for including this information it to better predict and check bolt patterns that are on the web of the beam(s). Fillet radiuses are per the various standards.

I haven't take the time yet to add in the few hundred standard sizes from my steel manual but as time allows I will continue to populate these fields. Also if there is specific requests for sizes or series of beam types I will accommodate those requests.

View model here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

-

I been thinking about putting on a weekly one hour webinar where I can demonstrate the latest features of the plugin and then take additional questions from the audience. Would there be any interest in this?

-

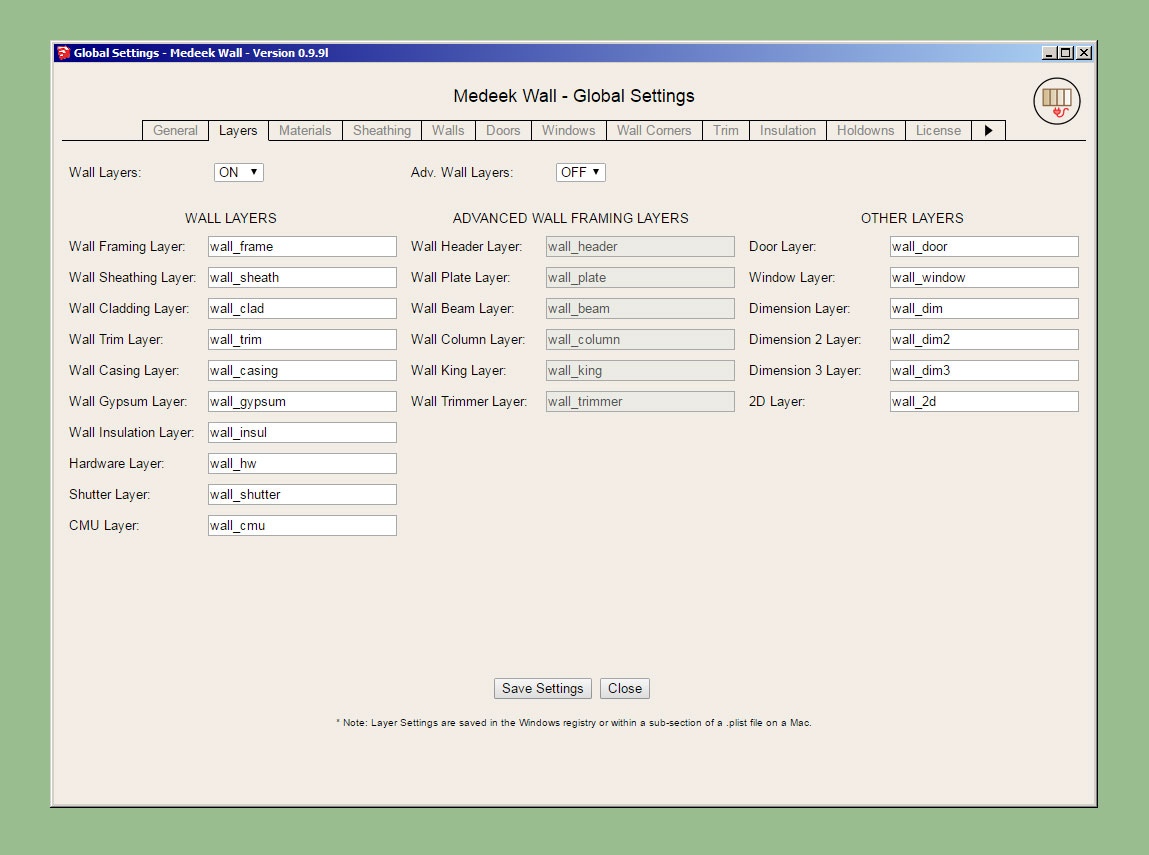

Version 0.9.9l - 11.16.2018

- Added an option to include 2D wall geometry in 3D modes (Framing, No Framing, CMU).

- Added an additional layer for 2D geometry.

- Added customizable colors for labels, 2D wall geometry, and 2D features (windows, doors, columns etc...)

The custom colors for the labels, and 2D geometry is per a discussion with a client today. Hopefully this upgrade will help facilitate bringing the 2D geometry into layout for creating floor plans.

-

On a related note I just noticed John Brock's new book has been released:

Amazon.com: SketchUp for Builders: A Comprehensive Guide for Creating 3D Building Models Using SketchUp: 9781119484004: Brock, John G.: Books

Amazon.com: SketchUp for Builders: A Comprehensive Guide for Creating 3D Building Models Using SketchUp: 9781119484004: Brock, John G.: Books

(www.amazon.com)

I think this will be a seminal work on incorporating SketchUp into the residential design process. I've already gone ahead and pre-ordered my copy.

-

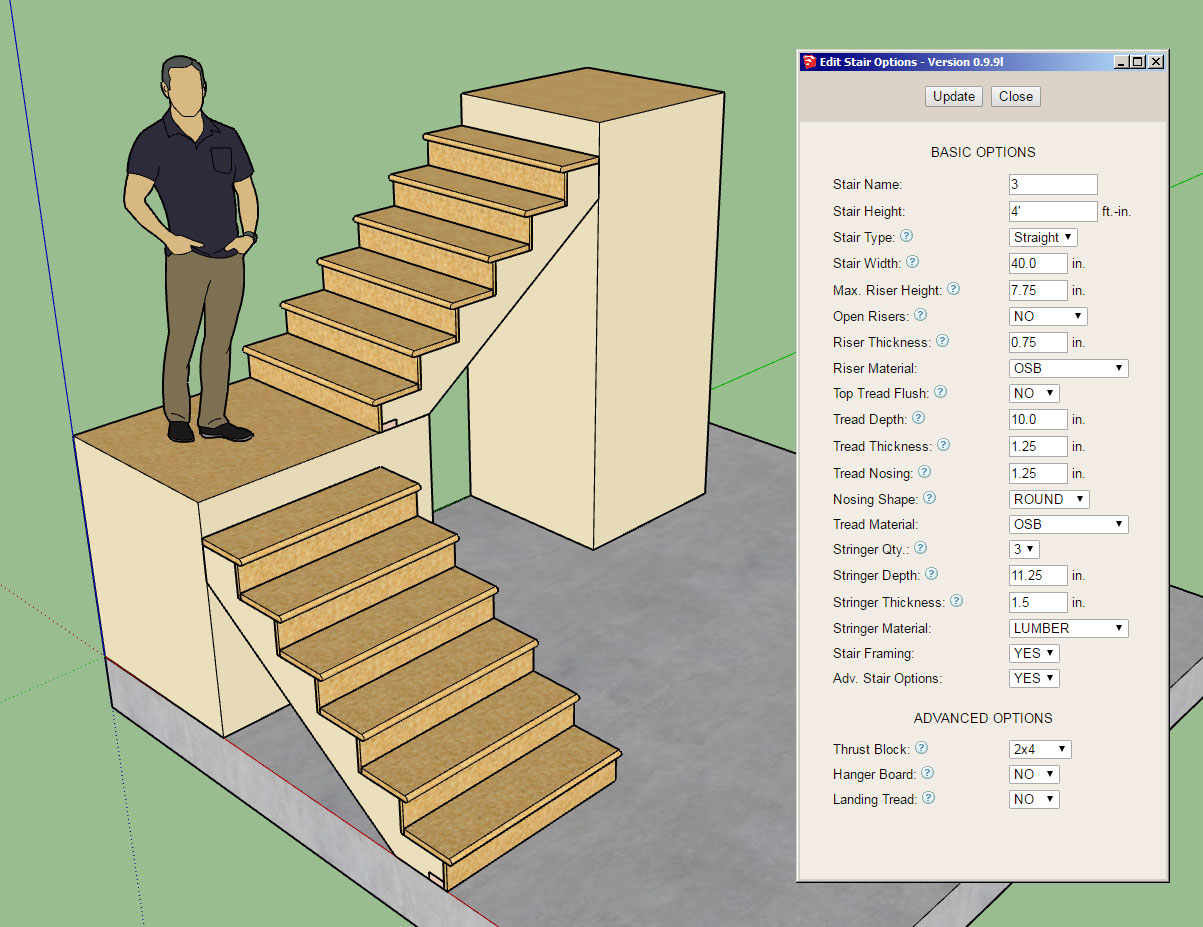

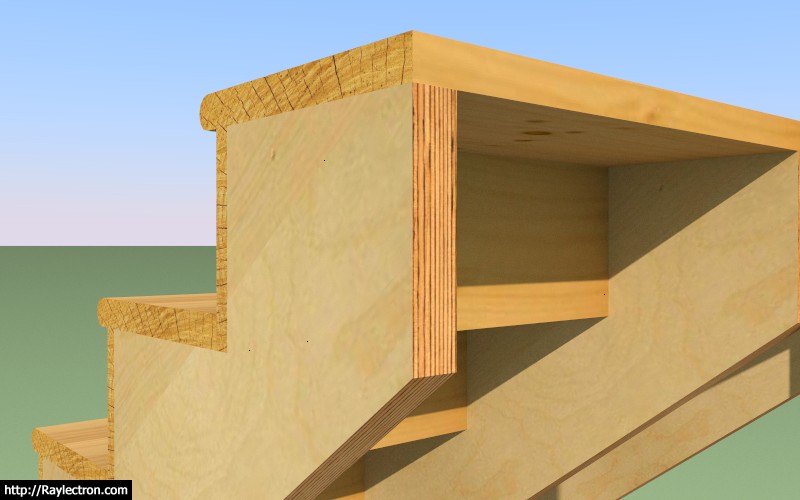

First look at the output of the Stair Module:

Note, that only straight runs of stairs will be available for now, however it is possible to create L and U shaped staircases just by combining straight runs as shown and framing in a landing.

View model here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

I will probably need one more day to fine tune it completely and finish adding in the hanger board and landing tread advanced options.

Future advanced options will be landings, hand rails, skirt boards etc...

The stringer algorithm is really the core of the module and drives everything else. The logic was not nearly as complex as I initially thought it might be, regardless it was a blast to work through it and turn the math into reality.

-

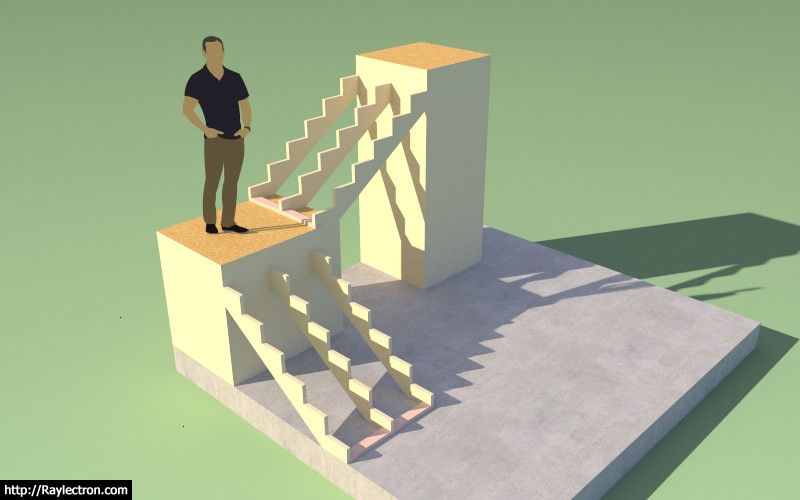

Had to jump through a few hoops to get the materials/textures to all work out correctly but I'm pretty pleased with the way its coming together:

LVL stringers with timber (wood grain) risers and treads.

-

Wow! Looks great!

-

Version 0.9.9m - 11.21.2018

- Added the stair module (straight run only) with the following advanced options: thrust block, landing tread, hanger board.

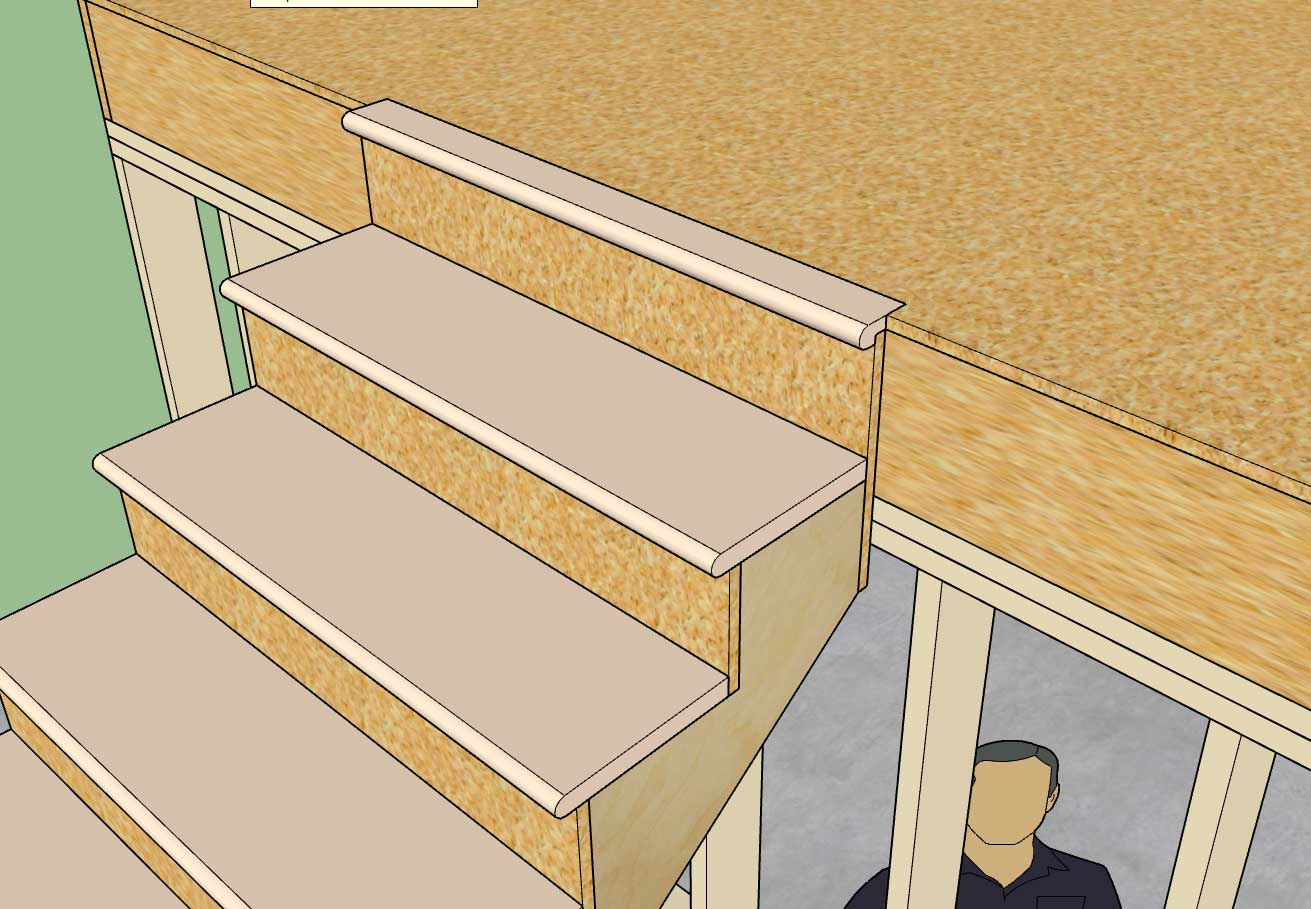

Hanger Board and Landing Tread:

Landing Tread:

There are quite a few options with the stair module so I will need to make another tutorial video explaining the usage of these parameters. I have provided tool tips next to each option in the draw and edit menus to help explain what each is.

A few items with the draw tool:

1.) First select the top of the stairs location and then select a point for the bottom of the stairs. The preview wireframe should be fairly explanatory as to the location and geometry of the stairs that will be created.

2.) Once the first point is selected you can lock to an orthogonal axis (0, 45, 90, 135 deg.) or direction by repeatedly clicking the "Ctrl" key.

3.) Once the first point is selected you can also toggle the placement of the stairs by repeatedly clicking the down arrow. The justification is: Center, Left, or Right.

4.) As with the other HTML draw menus, you update/change your parameters and then click the Update button to make them live. You can leave the menu open while drawing your stairs. Hitting the space bar will exit the tool, hitting the ESC key will reset the tool.

With the draw and edit menus you will notice that for the tread and riser material you also have the option of utilizing materials found in your custom library. The stringer material is limited to certain specific material types (at least for now).

This is a completely new module so I expect there may be some minor issues and additional features that will be requested.

I still need to create the global settings tab for the stairs so that default parameters can be set for each option. However, it is not critical to the function of the module.

-

Honestly, another plugin with plugin on this one. I could have added it to the Truss Plugin or even separated it out as its own plugin, for now though it will live within the Wall Plugin. The code base is logically separated from the rest of the plugin so moving it would be a non-issue if the time comes.

I think you use this module once and you will never go back to manually creating stairs or laying out stringers again. I know I certainly won't. The automation afforded by the API is stroke of genius, with it almost anything can be created. At some point I really want to try out my artificial life experiment that I've been mulling about for a while now.

-

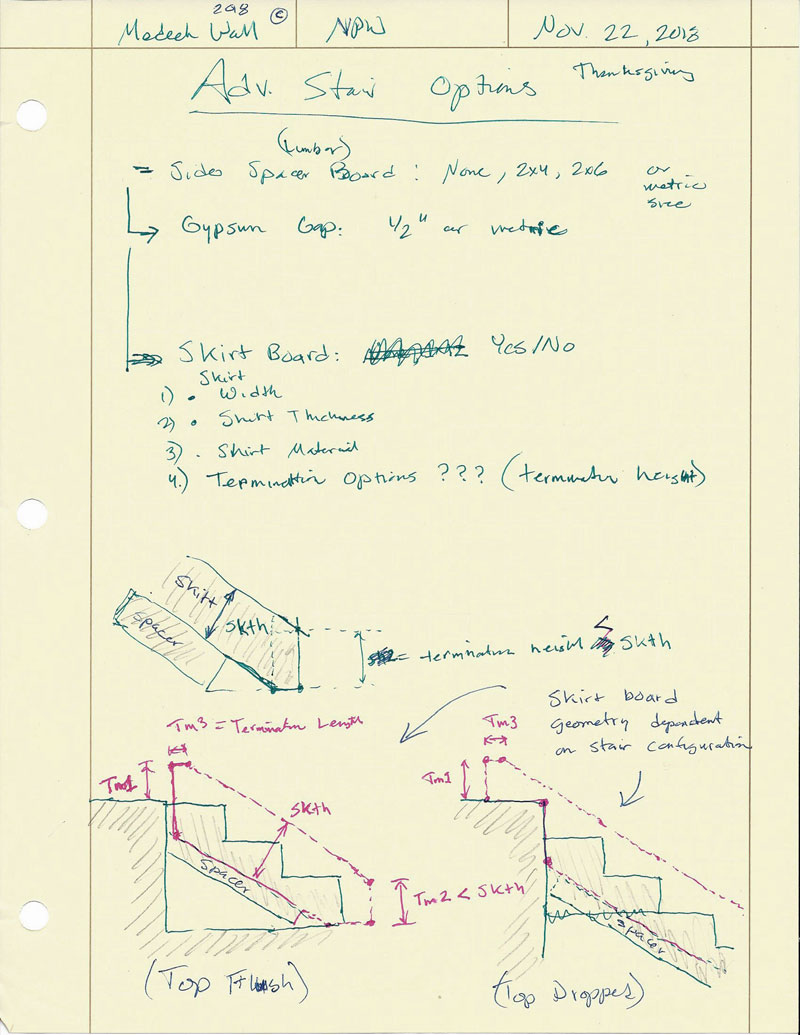

After some excellent feedback this morning I am considering adding in additional options for side spacers, gypsum gap, and skirt boards.

Everything is fairly straight forward except for the skirt boards. The question arises on how to best terminate the skirt, see image below:

-

I'm not sure if my scribbling is readable but the bottom diagrams try to explain possible configurations and parameters for the skirt board(s):

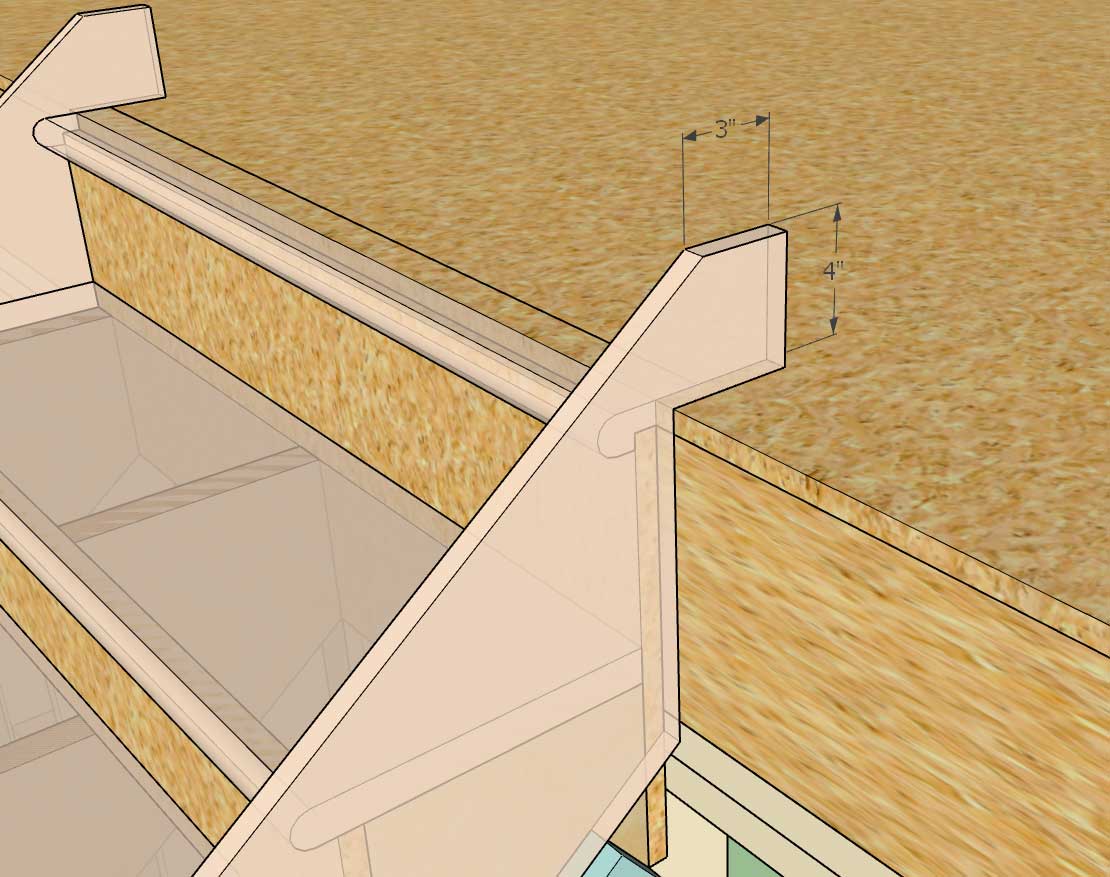

I think I can reduce the skirt board configuration down to three parameters:

- Terminal Height Top

- Terminal Length Top

- Terminal Height Bottom

-

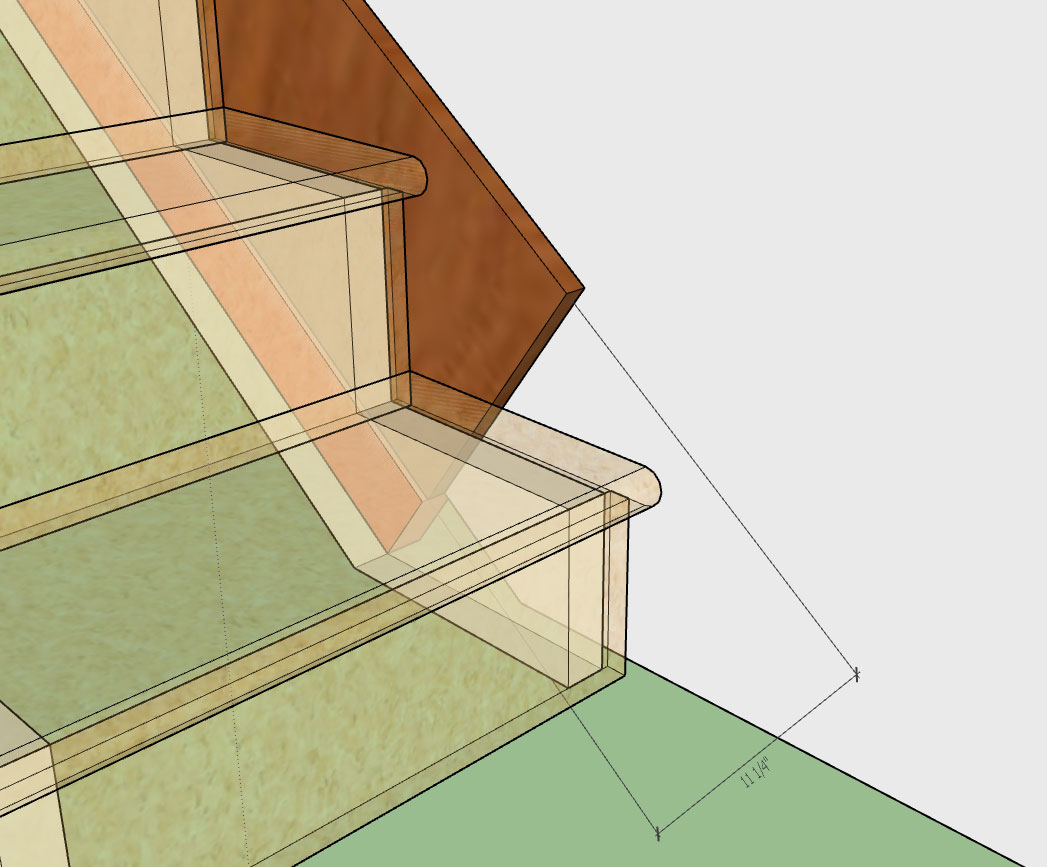

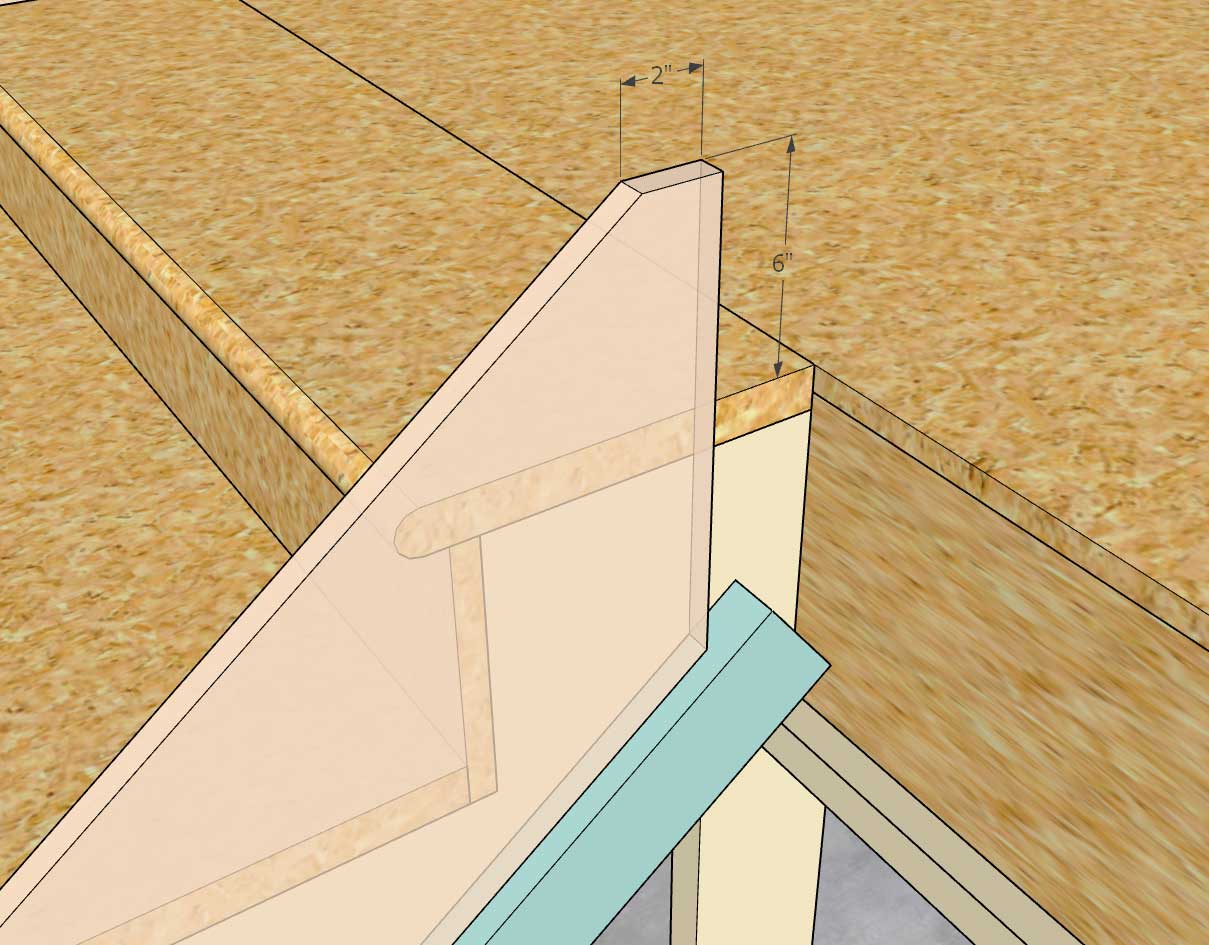

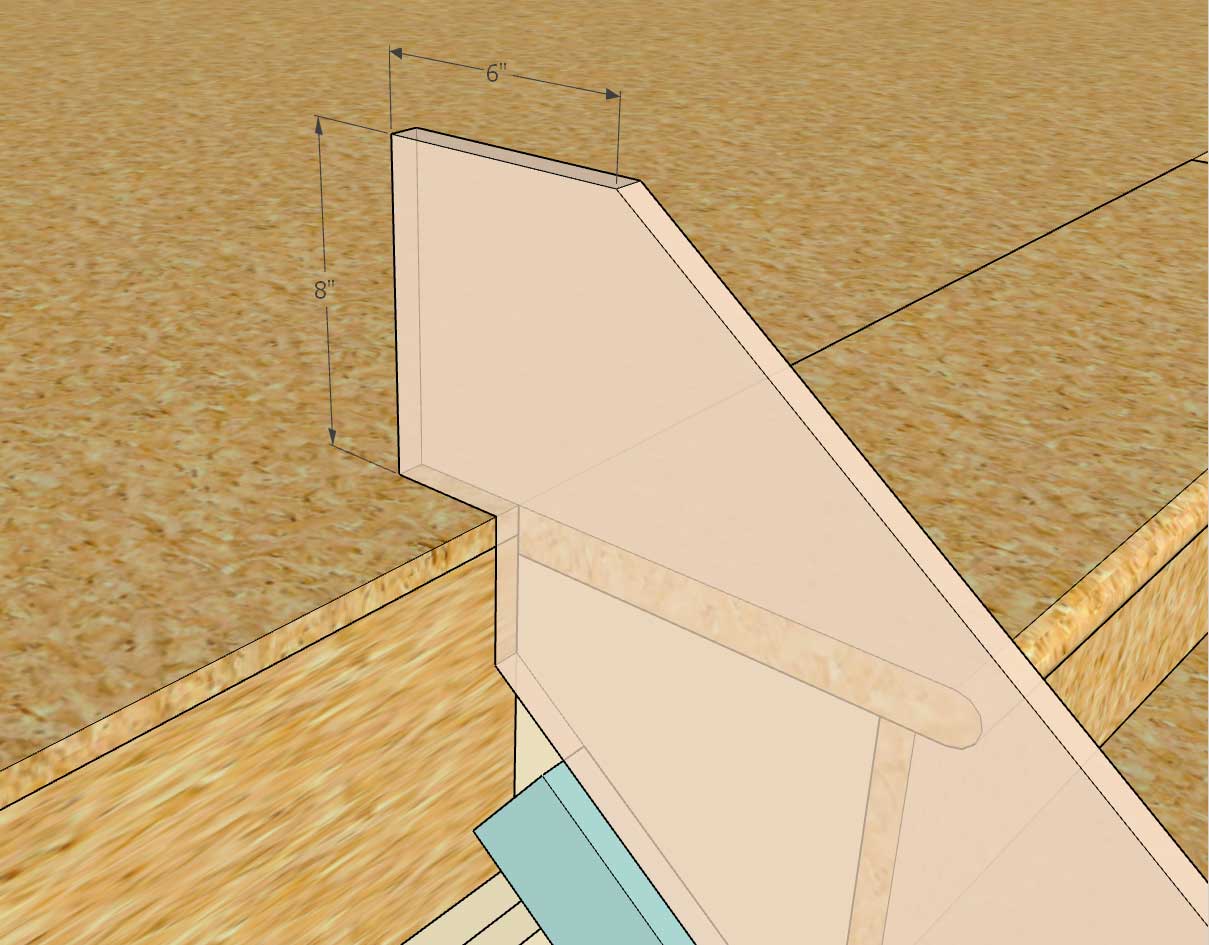

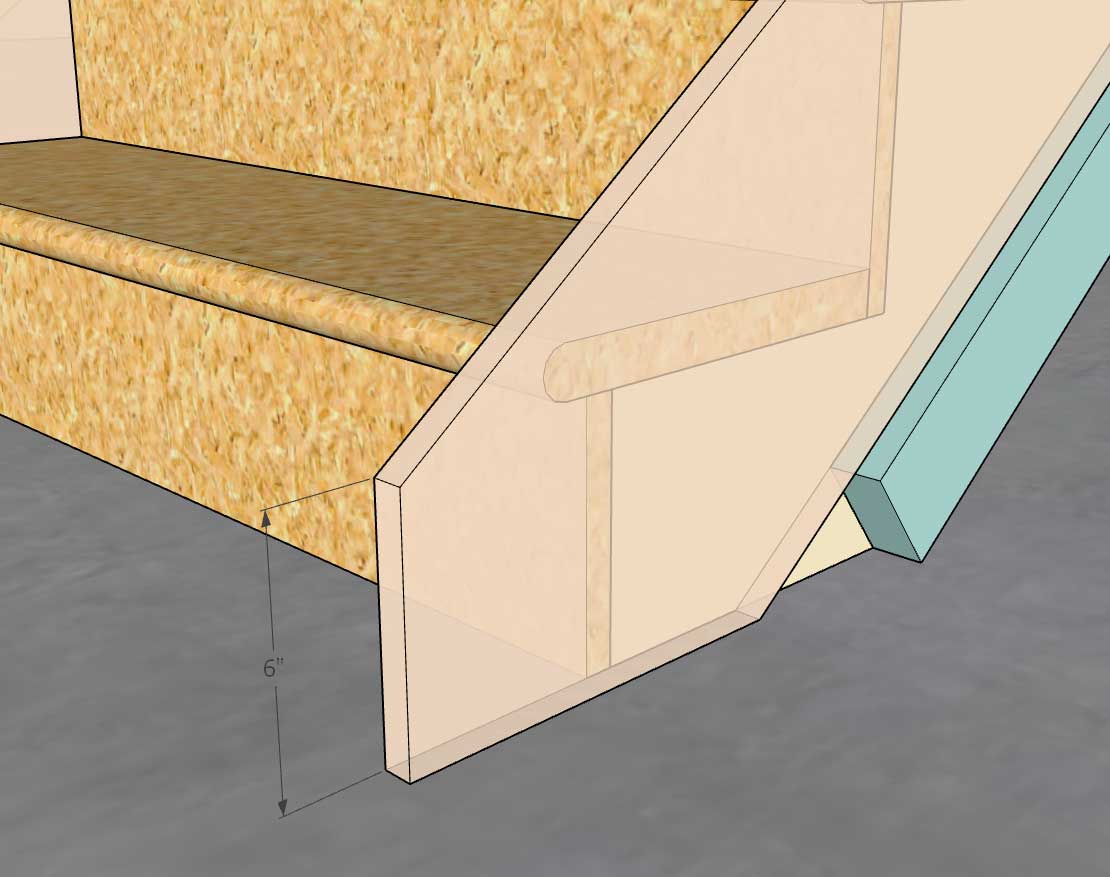

The diagrams were not very legible so I created a few details to explain the skirt board end configurations:

If these terminations look good I will begin adding in the logic to create them.

-

Some feedback on the other forum with regards to additional height requirements if a finished floor is installed has introduced some complications. I have given this some extra thought and my observations are thus:

1.) Where wall-to-wall carpet is being installed the way I have it laid out seems to be correct.

2.) The first point you select to position the stairs is the "Finished Floor" height. So if you need an extra 3/4" for a tile or wood flooring you would select a point that is 3/4" higher than the sub-floor. However, if the skirt boards are supposed to be installed prior to the final flooring then this would not be quite correct since they (their horizontal cut) would need drop 3/4" so that they meet the top landings subfloor.

3.) Similar sort of issue at the bottom of the stairs but slightly different. In this case the stringers will rest on the sub-floor, the bottom tread needs an extra 3/4" of rise, and the skirt boards will probably rest on the sub-floor/slab as well.

Question: Will the skirt boards always rest on the sub-floor or should they rest on the finished floor?

Conclusion: I need to add two extra parameters to the module to account for an additional thickness due to finished floors being installed. Since the finished floor on each level may be a different height (or carpet) we need a separate parameter for top and bottom. If I include a finished floor offset, the correct way to select the points for the stairs would be sub-floor to sub-floor.

- FF Offset Top (default to zero or 3/4"?)

- FF Offset Bottom (default to zero or 3/4"?)

P.S.

In addition to the three parameters for the skirt boards mentions above:

- Terminal Height Top

- Terminal Length Top

- Terminal Height Bottom

I will also need to include an offset parameter for the skirt boards since we can't be sure that the designer will want to install the skirt board directly onto the sub-floor (it might rest on the finished floor). Actually these parameters should be simple YES or NO parameters (with the offset equal to the finished floor offset from the parameters above) but there may exist a situation where the skirt board may be slightly lifted off of the finish floor so they each need to have a dimension associated with them.

- (Skirt) FF Offset Top (default to zero)

- (Skirt) FF Offset Bottom (default to zero)

Advertisement