Medeek Wall Plugin

-

Tutorial 37 - Moving Walls (16:03 min.)

-

Here is a todo list for the Wall Plugin, some ideas that I am currently floating:

1.) Global Settings Import/Export

2.) Wall Numbering Tool

3.) Wall Corner Tool

4.) Adding more dimensions and additional details to the framing dimension option.

5.) Max. wall panel length optionThis list is not in any particular order. The wall numbering tool would be quite easy to implement and quite useful in my opinion. Currently one can change the wall numbers/labels however it is a bit laborious since the edit menu must be accessed for each wall panel that needs updating.

-

Version 3.2.1 - 07.25.2023

- Added the Medeek Wall Tools II toolbar.

- Added the Wall Numbering tool to the Medeek Wall Tools II toolbar.

- Added the Edit Corners tool to the Medeek Wall Tools II toolbar.

This update is for Mike and Larry, but I think it will prove useful to many others as well. I will need to make another tutorial video explaining these two new tools.

-

Tutorial 38 - Wall Numbers and Corners (12:05 min.)

-

Version 3.2.2 - 07.26.2023

- Enabled the use of custom materials for sheathing, cladding and gypsum within the Sheathing tab of the Global Settings.

- Enabled the use of custom materials for cavity insulation within the Insulation tab of the Global Settings.

This update per customer request.

-

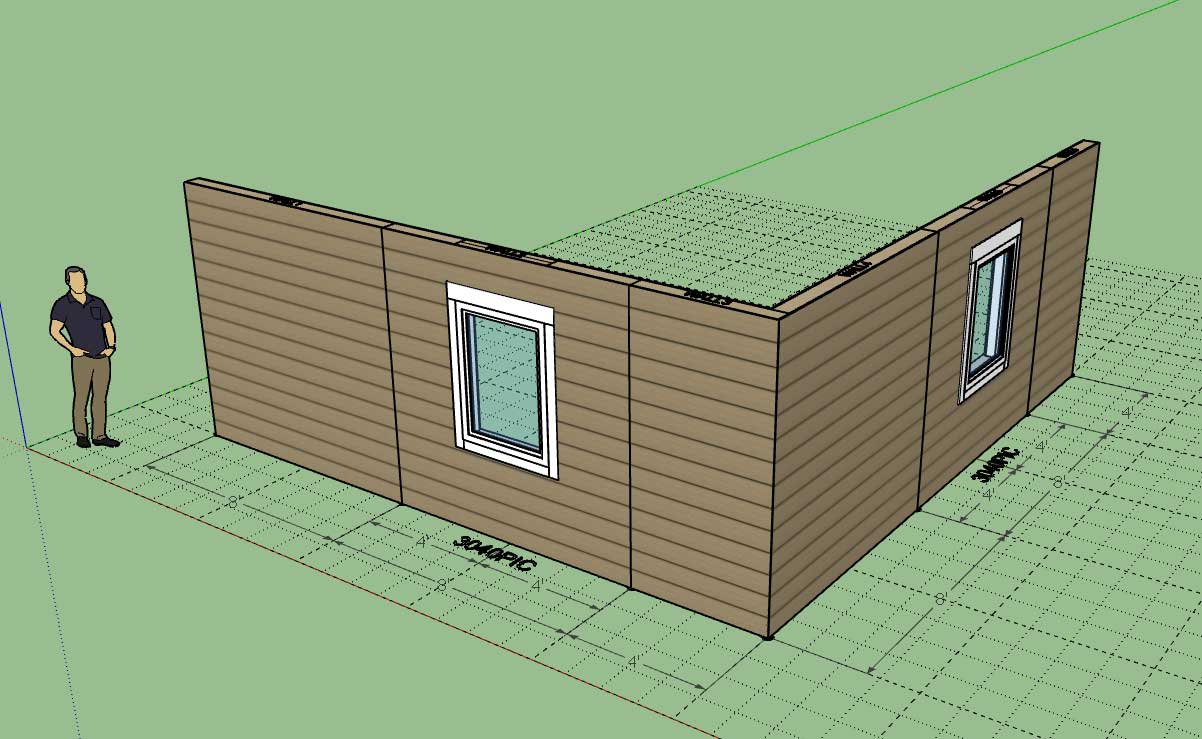

Most of the most recent updates to the Wall plugin have come from the users of the plugins but this morning after sitting down for a quick breakfast and just pondering the wall drawing process, in particular the usual method of drawing external walls, I came to a sudden realization of sorts.

Most of the time the designer/architect has already figured out the basic outline of the structure (ie. the polygon or polyline that will determine the placement of the external walls). In SketchUp a closed polyline can be represented as a face.

The current draw wall tool is very similar to the polyline stemwall tool in the foundation plugin, the user carefully picks the points that constitute the wall perimeter, one point at a time. Overall this method is not bad in my opinion and is reasonably speedy however what if one could simply click a face (of a polygon that is perpendicular to the z-axis) and then the wall plugin simply traced around the polygon and drew all of the walls automatically.

This tool would achieve two things:

1.) It would be quicker than picking one point at a time and for a complex perimeter would be a significant time saver.

2.) It would also help eliminate errors in picking the points one by one.Thoughts?

P.S.

Along the same lines I've also thought about a similar algorithm for drawing interior walls however the issue there becomes which way does the wall face (ext vs. int) when it is drawn. This is where the designer has to make some decisions and I don't really have a good way to automate this or somehow predict what the designer would do in each case.P.P.S

This same "Face" algorithm will also be used in the new Floor plugin, so rather than having to pick each point to create a new floor assembly the user can alternatively just pick a pre-constructed face. -

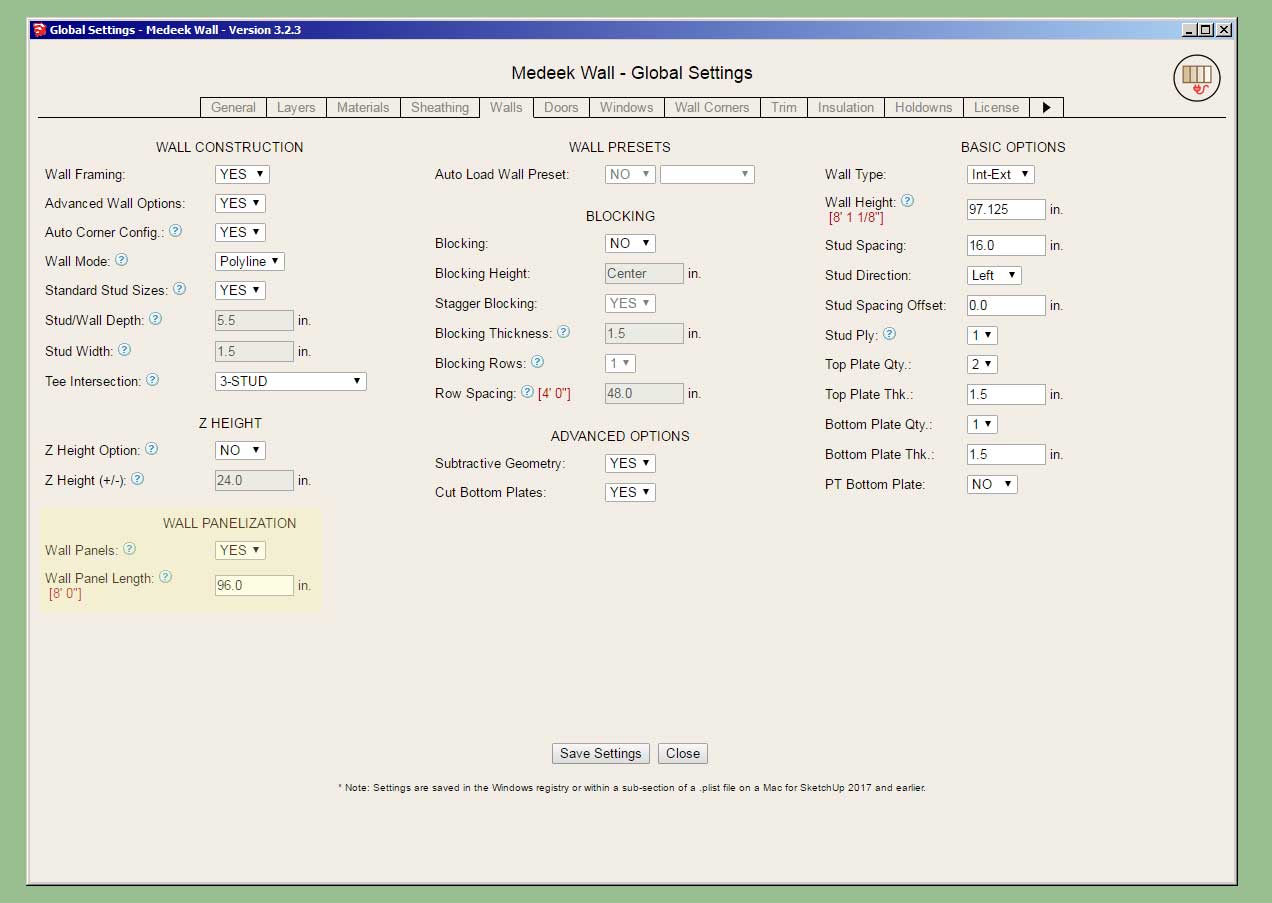

Version 3.2.3 - 07.30.2023

- Updated the stats logging for all wall types in order for the estimating module to provide more granular data for wall top plates.

-

Version 3.2.4 - 08.02.2023

- Fixed a minor bug with the SW module and SW materials.

-

Version 3.2.5 - 08.06.2023

- Added two parameters to the Walls tab of the Global Settings for Wall Panelization.

- Enabled wall panelization for rectangular walls.

-

Version 3.2.5b - 08.06.2023

- Added a hotkey (Up key) to toggle wall panelization ON or OFF within the Draw Wall tool/menu.

-

Tutorial 39 - Wall Panelization (8:52 min.)

-

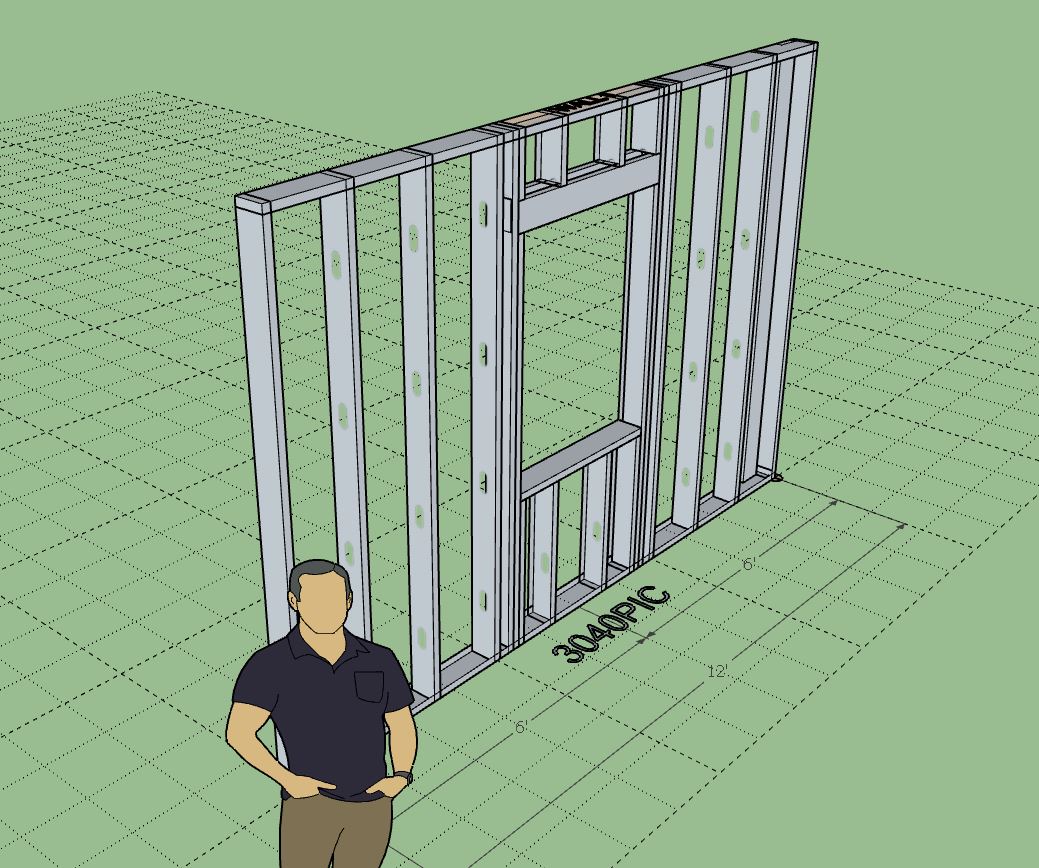

Version 3.2.6 - 08.09.2023

- Fixed a bug with stacked openings and plan dimensions.

- Added "Subtractive Framing" to the Wall tab of the Global Settings.

- Enabled "SUBTRACT_FRAMING" custom boolean subtraction for all wall types.

This now gives us a workaround for non-aligned stacked windows and doors. This update per customer request.

-

Tutorial 40 - Stacked Windows (10:40 min.)

-

Version 3.2.7 - 08.25.2023

- Updated steel studs and plates for all wall types.

- Fixed a bug in the statistics module for the gable walls.

Previously the steel studs and plates were merely cosmetic, now the are modeled a bit more realistically (however less attractively in my opinion). This update was specifically requested by users who specialize in steel stud framing and who wanted a more accurate model (stud length and channels for top and bottom plates) when it comes to steel framing. The plugin was never initially designed for steel framing and because of that I still consider the steel framing option more of a cosmetic model than an actual realistic model, but this latest update gets us a little closer to that objective.

-

Version 3.2.7b - 08.26.2023

- Minor updates to the window and door framing modules with regards to steel framing.

-

Version 3.2.7c - 08.28.2023

- Additional updates for steel framing for metric templates/units.

-

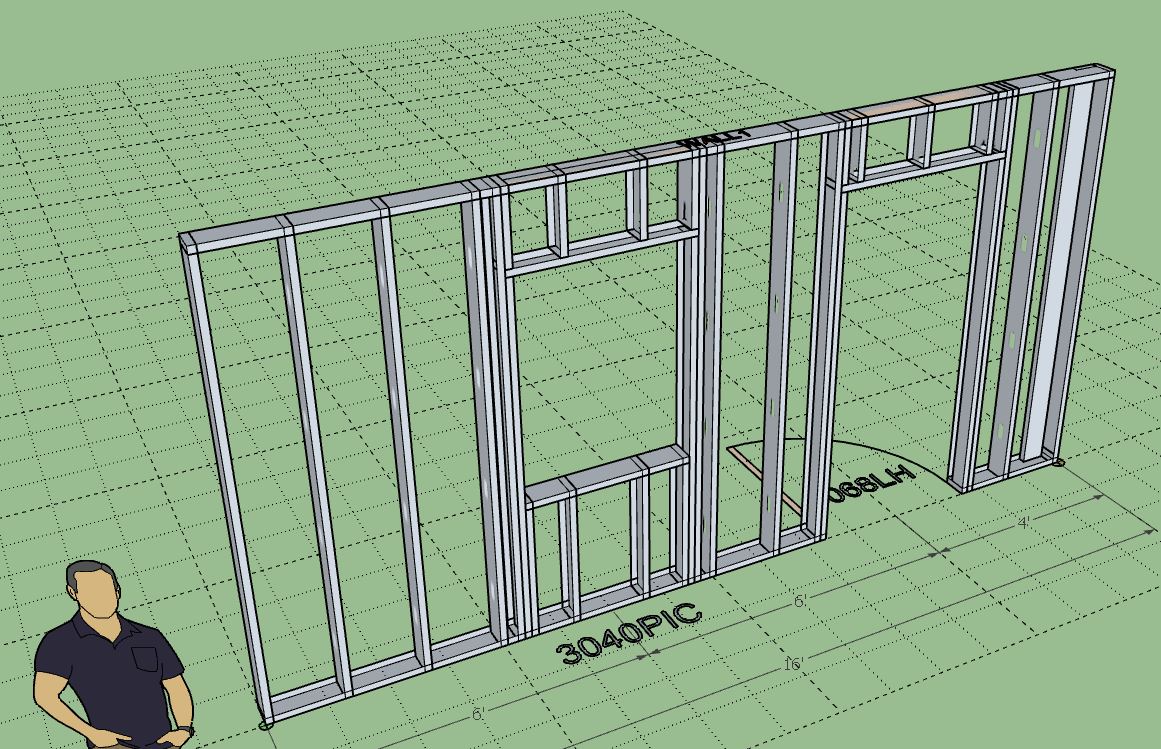

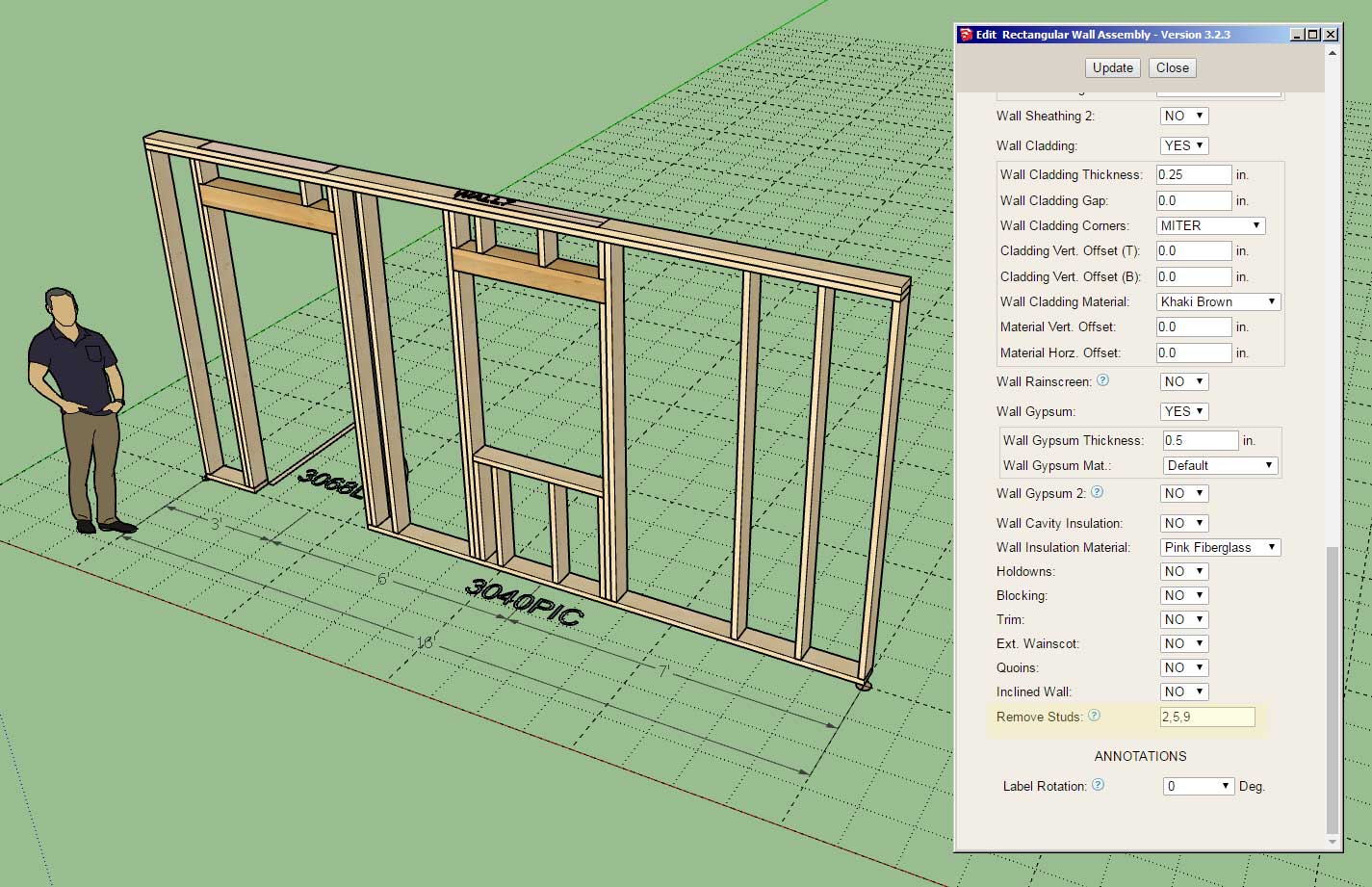

Version 3.2.8 - 09.07.2023

- Enabled a feature to selectively remove specific studs from any wall assembly.

Note that this feature/option is very similar to the recent truss removal feature added to the Truss Plugin for common trusses and attic trusses. I've had a number of requests to add something similar into the Wall Plugin so specific studs could be removed. This update is per multiple customer requests.

I may make a tutorial video for this new feature but I do think it is fairly self explanatory.

-

Version 3.2.8b - 09.07.2023

- Fixed a bug with the shearwall edit tool.

- Added directional logic into the Move Opening Tool's text entry method.

-

Tutorial 41 - Selective Stud Removal (5:37 min.)

-

I now have a system in place for those interested in a "lifetime" (30 year) license for the mdkBIM bundle. If you do purchase the "lifetime" bundle license I will also throw in a lifetime license for the Electrical plugin. The cost is $980.00 USD which is 3.5X the regular bundle price of $280.00 USD.

If you are interested please email me direct and I will give you instructions how to proceed. The same 14 day refund policy applies, so please be aware of that (5% restocking fee):

A lifetime license means that you have free upgrades and no renewal fees for the next 30 years (until 2053).

Advertisement