3D Truss Models

-

Version 2.6.7 - 02.09.2020

- Fixed a bug in the text input method of the draw menu for complex rafter roofs.

- Added a T1-11 built-in material into the material library.

-

Version 2.6.8 - 04.10.2020

- Fixed a show_modal bug for macOS in the Timber Truss HTML menu dialog.

With this latest release I've had to migrate to the .rbe encryption system so this version will no longer run on SketchUp 2015 or earlier.

-

Version 2.6.9 - 04.11.2020

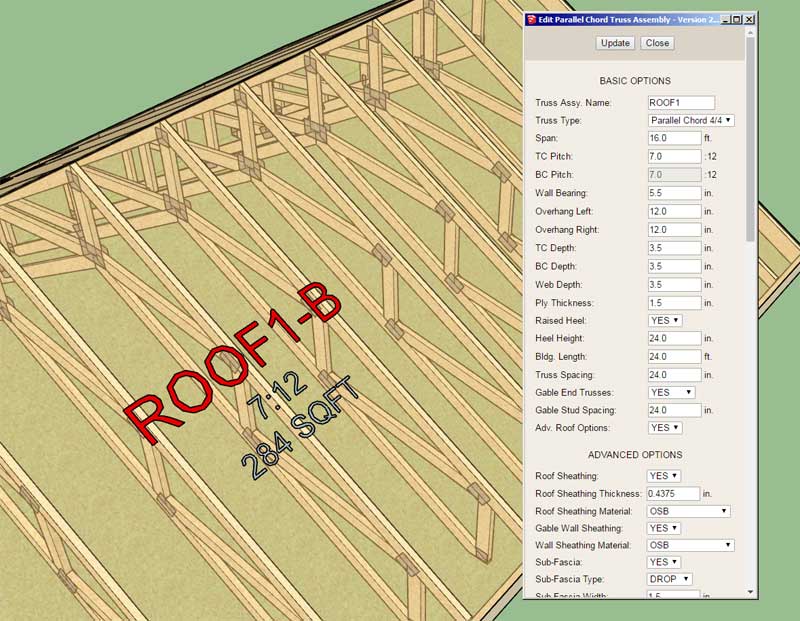

- Enabled the "Edit Truss Assembly" function for all parallel chord trusses (imperial and metric units).

- Labels and callouts added to parallel chord trusses.

There are still a number of truss types and rafter roofs that still need edit capabilities, I am slowly working through this list.

-

Version 2.7.0 - 04.12.2020

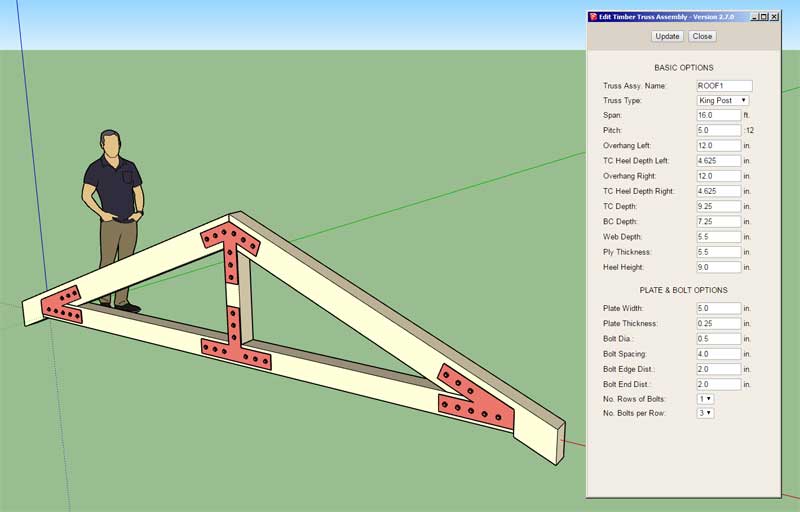

- Enabled the "Edit Truss Assembly" function for all timber trusses (imperial and metric units).

-

Version 2.7.1 - 04.13.2020

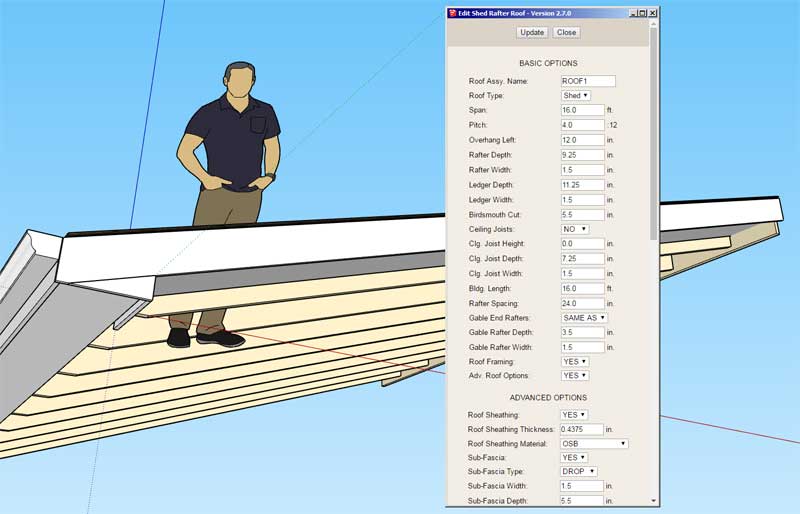

- Enabled the "Edit Roof Assembly" function for shed w/ ledger rafter roofs (imperial and metric units).

- Enabled soffit and fascia for shed w/ ledger rafter roofs: boxed, gable, angled.

- Enabled a roof cladding extension parameter for shed w/ ledger rafter roofs.

- Added the option in the shed w/ ledger rafter roof edit menu to specify a separate front and back overhang length.

- Enabled a "No Framing" mode for shed w/ ledger rafter roofs.

-

Skylights have not been on my official todo list but now they are.

I've actually been tossing the Skylight idea around for a while now, how best to implement it within the various roof modules. I've got some ideas already but I haven't finalized it yet.

Does anyone have any specifics or suggestions on the actual skylight models/components that I should use. Specific brands, reference drawings, that sort of thing.

My thinking is to have some fairly generic skylight models that the user could chose from. The skylight module would then bring these components into the model and also cut the corresponding holes in the roof cladding and sheathing. I would also have a tool for editing and deleting a skylight. As far as moving the skylight on the roof plane, I would allow the user to simply click into the roof assembly and moving the skylight with the native tools as they see fit, this would be the simplest way of handling re-positioning.

Again, I'm still tossing this idea around, trying to shake out the best system for implementing it, any feedback is appreciated.

-

Velux has their official models in the warehouse but as usual there are too many details in these models, so I had to create my own low poly versions that are dimensionally accurate:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

-

@medeek said:

Velux has their official models in the warehouse but as usual there are too many details in these models, so I had to create my own low poly versions that are dimensionally accurate:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

Different manufacturers have different sizes. A single well constructed DC, where you can enter the overall sizing on a dialogue, would probably be more useful and cause less bloating of the extension?

-

First look at the Skylights Toolbar:

-

@juju said:

Different manufacturers have different sizes. A single well constructed DC, where you can enter the overall sizing on a dialogue, would probably be more useful and cause less bloating of the extension?

I've thought about this however there are quite a few different types of skylights (ie. surface mount, curb mount, round etc...) so it would seem to make more sense to model a few of the most common ones and then allow the user to drop their own custom skylights into the library folder. However, I do get what you are saying on this, I may need to give it some more thought.

-

@medeek said:

I've thought about this however there are quite a few different types of skylights (ie. surface mount, curb mount, round etc...) so it would seem to make more sense to model a few of the most common ones and then allow the user to drop their own custom skylights into the library folder. However, I do get what you are saying on this, I may need to give it some more thought.

Maybe touch base with Yoni at FlexTools, they seem to have that process licked!

-

Surface mount and curb mounted (typically on 2x6 framing over roof deck) are common. Velux is probably the standard though there are other types out there. In our area it's mostly Velux or something like that due to stringent energy requirements. You could have some of these, especially the ones meant to go into 24" o.c. framing. Then if you want branch out to some pyramidal or gable style skylights.

-

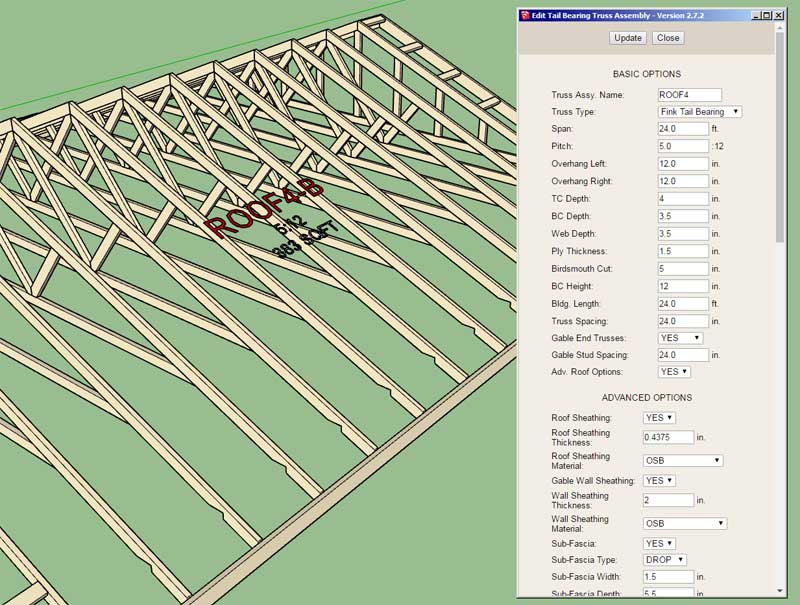

Version 2.7.2 - 04.24.2020

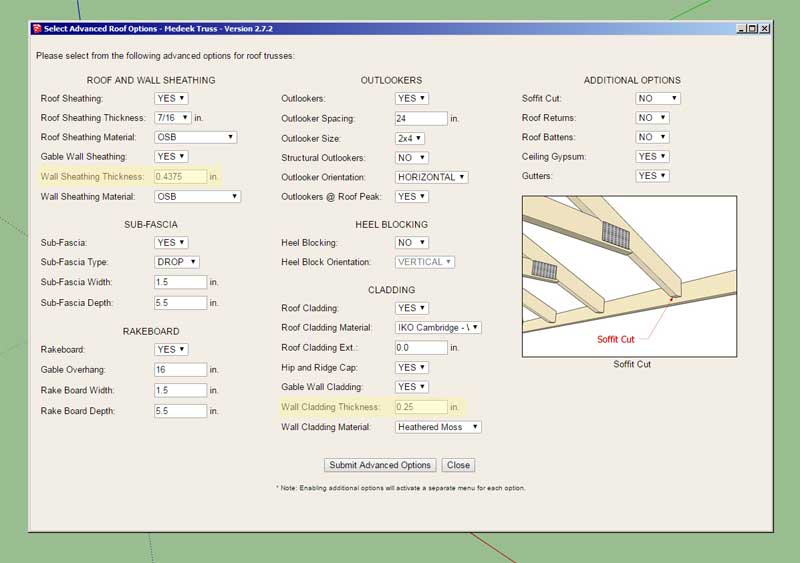

- Added wall sheathing thickness and wall cladding thickness parameters to the advanced options for trusses.

- Enabled advanced options for tail bearing trusses.

I still need to enable editing and labels for tail bearing trusses.

-

Version 2.7.2b - 04.24.2020

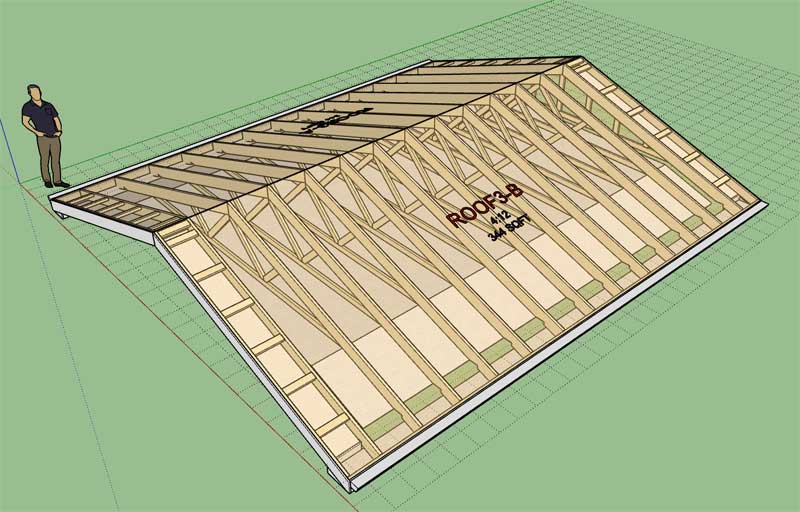

- Enabled the "Edit Truss Assembly" function for all tail bearing trusses (imperial and metric units).

- Labels and callouts added to tail bearing trusses.

This update also resolves a potential bug that could cause the plugin to go into a infinite loop if the birdsmouth cut exceeds the depth of the top chord of the truss. If you are using tail bearing trusses I highly recommend upgrading to this latest release.

The updated module is now properly creating the gypsum on the underside of the truss (three pieces).

-

Do you have an option for strapping between the trusses and the gypsum?

-

@db11 said:

Do you have an option for strapping between the trusses and the gypsum?

Yes, for some truss types it is enabled.

-

OK, thanks.

One other quick question: when do you expect to have your gable wall module completed?

-

Maybe I'll wrap that up next. I really want to get this skylight module up and running though in the next couple of days.

-

Version 2.7.3 - 04.26.2020

- Added a Global Reset button in the General tab of the Global Settings.

-

Version 2.7.4 - 05.02.2020

- Fixed a bug with the soffit and fascia module for all truss types.

This bug fix is specifically for the boxed soffit for truss roofs. Previously if one did not enable the fascia but enabled the soffit then it would throw an error. There may be other similar bugs in this module or others so I am constantly testing combinations of various parameters to make sure no interdependencies have been overlooked.

Advertisement