[Poll] - engineer this table

-

Hmmm. You need a friendgineer.

Can't believe it would be that expensive.

Can't believe it would be that expensive. -

@mitcorb said:

Hmmm. You need a friendgineer.

Can't believe it would be that expensive.

Can't believe it would be that expensive.heh.. i have one of them and he'd probably have a look for no charge.. thing is, he's not in the 'immediate' circle of friends so i don't want to waste a possible favor with this table..

but yeah, i'll just show it to a local engr.. surely won't be more than a couple hundred. -

I haven't looked at it carefully, but have you considered other materials. Good ply and nice edge trim, light and easily replaced.

Or fibreglass, simple fabrication, durable, light etc etc

Epoxy casting, bloody expensive but wonderful finish.I think my point could be that it depends what the full end use is. Are you making one or 300? Is tooling up cost effective etcetc

-

@box said:

I haven't looked at it carefully, but have you considered other materials. Good ply and nice edge trim, light and easily replaced.

Or fibreglass, simple fabrication, durable, light etc etc

Epoxy casting, bloody expensive but wonderful finish.I think my point could be that it depends what the full end use is. Are you making one or 300? Is tooling up cost effective etcetc

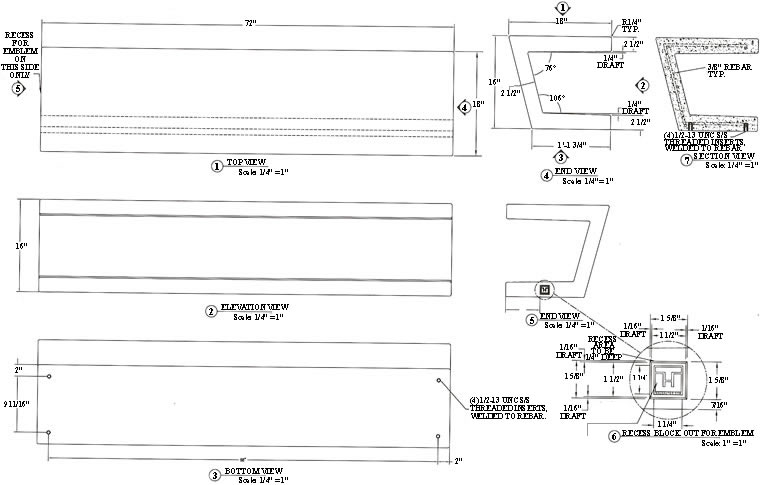

first thought was wood since i'm a woodworker.. (and this is still, basically, a wood project.. the form work is what will require the most skill).. i already have the necessary tools to build this.. concrete or rebar isn't that expensive..

the most expensive thing in the design are the flanges/threaded uprights and i'd have those subbed out. (~ $50 per flange / $50 per upright)..but that stuff aside, i'd still be up against the same sort of issues if i just took the same shape and made it of a different material.

i'm making a total of 4 different pieces.. a bar and 3 tables.. none are the same shape and the forms will be trashed (about $500 in form material)

-

Yeah all of that fits, I know you are a wood man which is why I don't understand the concrete. Why make a negative wood former to caste when you could make a fantastic laminated wood positive.

-

boredom ?

(oh, and I mentioned concrete at one of the meetings and they loved it.. basically, at this point, they're buying concrete tables/bar top)

-

I love and use concrete a lot, and have built a lot of countertops over the years, and I wouldn't hesitate to build it as you have it designed.

Attached is a test done on Glass Fiber Reinforced concrete with no rebar, and it resists 1100 lbs befor breaking, so with rebar as per your design..... no problemBut if you really want to have some fun you should get into Fabric Cast Concrete.

-

Boredom in my book is written on the door to god's waiting room. If you want to make it make well for everything else there is IKEA

-

@jeff hammond said:

• high volume cafe/coffee house..

• one of those "i don't know - what do you want to build?" setups

• i want to build thisFrom an ergonomic (and potentially ADA) standpoint, long benches suck for folks with knee and/or hip injuries, since being anywhere other than the end basically means they're trapped in there until everybody else moves.

Then again, cramped and uncomfortable is the in thing for coffee shops these days.

-

@airwindsolar said:

@jeff hammond said:

• high volume cafe/coffee house..

• one of those "i don't know - what do you want to build?" setups

• i want to build thisFrom an ergonomic (and potentially ADA) standpoint, long benches suck for folks with knee and/or hip injuries, since being anywhere other than the end basically means they're trapped in there until everybody else moves.

Then again, cramped and uncomfortable is the in thing for coffee shops these days.

That's so people don't stay too long!!! NEXT CUSTOMER PLEASE!!!!!!!!

-

@airwindsolar said:

From an ergonomic (and potentially ADA) standpoint, long benches suck for folks with knee and/or hip injuries, since being anywhere other than the end basically means they're trapped in there until everybody else moves.

Then again, cramped and uncomfortable is the in thing for coffee shops these days.

comfort? this is brooklyn-- we only care about how many people we can cram into one spot

(i kid, i kid)

(i kid, i kid)but yeah, some of what you're saying was discussed already and if you saw the whole design, i think this actual table would make more sense.. as per a client request, this table is communal seating.. there are also some tables which are easier in/out and more 'private' (as well as a few standup/chair_less tables).. then one wall table with stools.

as i imagine it happening at least-- the two ends of this table will be occupied first and will be the most used areas.. when it's busy though, people will be able to sit in the middle without asking the people on the ends to move..

@dale said:

I love and use concrete a lot, and have built a lot of countertops over the years, and I wouldn't hesitate to build it as you have it designed.

Attached is a test done on Glass Fiber Reinforced concrete with no rebar, and it resists 1100 lbs befor breaking, so with rebar as per your design..... no problemBut if you really want to have some fun you should get into Fabric Cast Concrete.

thanks for your thoughts Dale.

i remember you posted something about the fabric casting a couple of years ago.. i'm hyped on the stuff and hope to find a use for it one day..i saw that video last night and found it impressive.. the spans/overhangs i have are less than the spans in the video so this table should be able to resist more weight than they've done.. not to mention this design has rebar in it as well.. to be honest, i'm now confident these spans won't break under normal condidtion- not even close.. my main concern now is the balancing or wether or not it will topple.. i'm just going to do a mock up and test it like that-- if it topples, i'll be able to make a tighter radius which should provide more stability..

here's a bench design i came across last night and to me, that's a lot more stress than what my design is calling for.. this bench is using the same #3 rebar and the cantilever is the same thickness (2.5").. if this thing holds up, my design definitely will.

i found quite a few objects which were similar in size/material with sections of it being under greater stresses than what i'm planning.. i think the one i've drawn will be o.k.

-

@futurepast said:

That's so people don't stay too long!!! NEXT CUSTOMER PLEASE!!!!!!!!

haha.. right.

the client didn't want booths.. she wants benches

@box said:

Boredom in my book is written on the door to god's waiting room. If you want to make it make well for everything else there is IKEA

boredom is the wrong word.. (well, it's the right word in my head but i'm not using the right definition for it)..

more along the lines of-- for whatever reason, this concrete/steel idea is exciting to me and i look forward to building it..

as long as i have that aspect going for me in a project, the project becomes fun and more easy..if i'm not excited to do it and i'm strictly working for the money, it becomes such a drag and the days feel twice as long..

something like that.

-

Ok then, can you add a "I really don't give a shit" Icon. So we don't expend any energy on the answers we give.

-

@box said:

Ok then, can you add a "I really don't give a shit" Icon. So we don't expend any energy on the answers we give.

rich would have to do that..

fact is, i do give a shit.. lots of what is being said has already been discussed/thought through so my responses are filling in the background info.

the stuff that i haven't discussed or thought through is the maths / forces which are happening here.. in fact, i don't even know how to do that..

it will be sweet when we get the ability to do this stuff in user friendly_ish programs.. basically, in this case, assign the material then turn on gravity.. apply side force.. have susan and sang jump on top.. etc..

ie- Engineering for Everyone!!

-

.

went with the 80%

pouring tomorrow

-

Nice update!

-

looking good.

I am curios how will you do round corners.good luck

D.

-

When the end comes... I want to be under this table.

-

forgot to update--

poured it.. wrapped it in plastic for a week while i was in seattle.. came back, removed the forms, sealed with tk6..

the thing is super solid/strong.

(in west texas now for a few weeks.. a little bit more work for this cafe once i get back to nyc.. i'll post a final update when all is complete)

-

Robust!

Advertisement