Matching holes through multiple objects

-

I often need to make arrays of matching holes through more than one object.

Examples:- riveting two pieces of sheet metal together. (Rivet fields can run to many hundreds of rivets in a single project.

- drilling matching holes for dowel joints.

- any mechanical assembly of multiple parts held together with fasteners.

Is there an easier way to accomplish this than using the push/pull tool on each individual hole in each individual object? I certainly hope so.

Thanks. JA

-

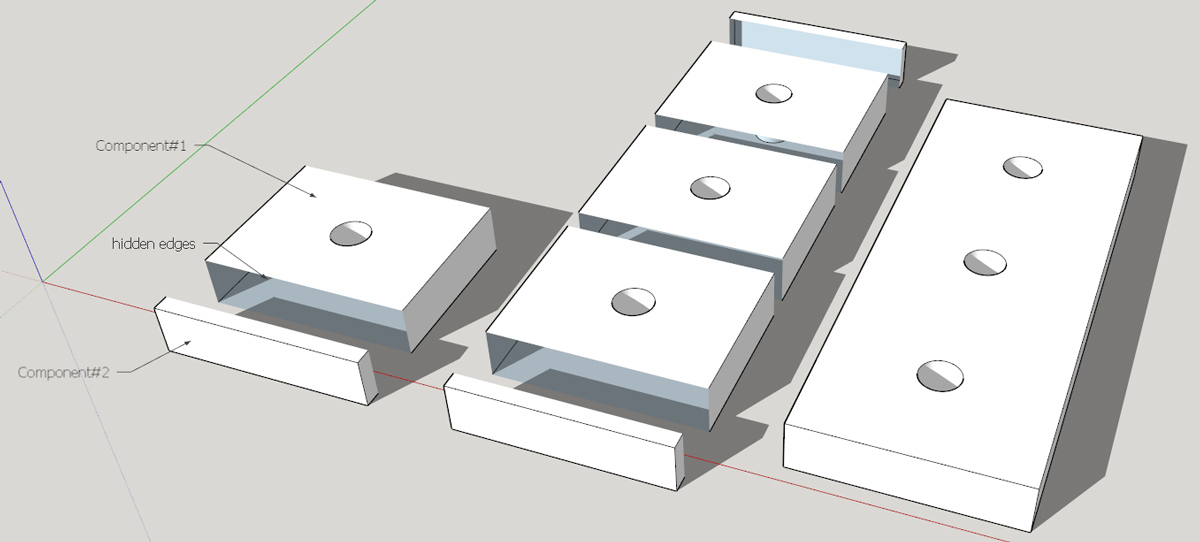

You could try this. In the attached SKP file a component is made of four hole-cutting components which fit the thickness of your material. Then array this component in the context of the faces of your material. Explode the components (ONCE). You are left with hole-cutting components on the faces of the material. However they may not be cutting holes. This is where you need to use ReGlue plugin by TIG. In this case it can be a task to select only the components and their face to work the ReGlue magic (it's OK to selct the face's edges too)--but that's all I got right now.

-

pbacot,

Thanks. I tried it & it helps with laying the holes out. But unless I'm missing something, you still have to select and delete the inside of each circle. I'm still hoping there is a way to automate the whole thing. JA -

They are hole-cutting components. As you see the components have no face in the circle. When they cut a hole on the face there should be nothing to delete. My description is the full process. Maybe a ruby could be written.

-

If your objects are solids, you can try Tak2hatas plugin hole on solid...

[screenr:1ts4j5l2]VBSN[/screenr:1ts4j5l2]

-

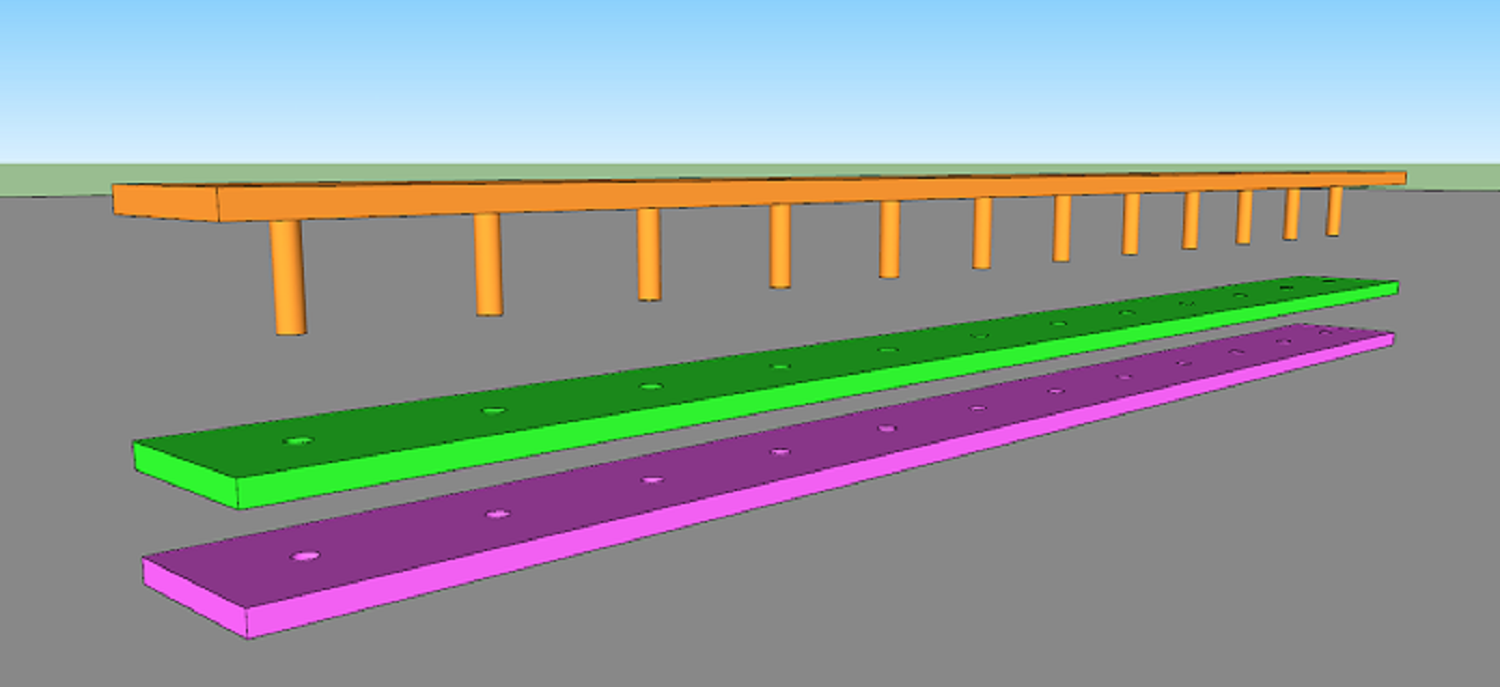

Cotty, Thanks for that. I also found a way to do it using solid tools -- see attachment. First create the top comb-like object by using array copy. Then create the "back" of the comb and join all together using union. Place the "comb" on the object(s0 to be drilled and use trim to punch the holes. Keep the comb in case you need to repeat or modify the action. JA

-

You could also just array a single hole section as a component to make your flat bar with holes.

-

Box, What's a "hole section"? JA

-

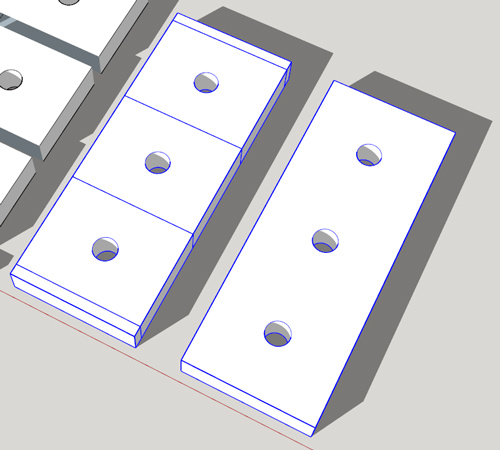

I just meant if you made one rectangle with a hole, make that a component and array it you get the same result, and you only had to make one hole.

It's an over simplification of what you want to do, but as your example shows everything the same size it's a simple way of doing it.

Your 'comb' works for things that aren't the same shape though. -

Box, Got it. Thanks.

-

A picture for Boxs suggestion...

-

Ah! This illustration raises a big issue, i.e., how to end up with a solid after such manipulations. I spend a lot of time "fixing" objects that started out as solids and still look OK, but in fact are no longer solids (Entity Information doesn't include volume). Solid status is needed to use solid tools and to export for 3d printing. For example, let's say I make a cube and punch a hole through it, and then decide to move the hole. If I select the entry and exit holes and move them with the move tool, the result may look good, but quite often SU says it's not a solid anymore. Fixing it involves using Solid Inspector and editing individual lines in X-ray mode with hidden geometry on - a real PITA. I often have to start over and create the object again from scratch. Big loss of time. Am I doing something wrong? Is there an easier way? Thanks.

-

@jalsina said:

how to end up with a solid after such manipulations.

After alignment, you can group all items of one object and explode all components in it. In the shown case, the resulting object will be a solid one...

@jalsina said:

let's say I make a cube and punch a hole through it, and then decide to move the hole. If I select the entry and exit holes and move them with the move tool, the result may look good, but quite often SU says it's not a solid anymore.

This shouldn't change the solid status. Do you have an example where this happened?

-

I don't have an example handy, as I obsessively fix such messed-up objects and don't keep the original messed up one. Very often, what used to be a round hole now appears as two circles on opposite surfaces, but with no void between them. If I click on the inside of a circle, one of two things happen: 1) I am able to highlight and delete the area inside the circle, which leaves an empty shell with a hole in it instead of re-creating the cylindrical through-hole I started with, or 2) clicking inside a circle highlights the whole face, as if the circle weren't there. Drawing a new circle over the old circle sometimes enables me to select the area inside it, sometimes not. Very frustrating when trying to rescue a complex object that has hours of work in it.

-

" Solid status is needed to use solid tools and to export for 3d printing. "

Now you tell me. I wouldn't have bothered with the hole-cutting component idea.

-

I like your comb idea, but a row of individual cylinders made into a single component make a solid component--you don't need to connect them. It sucks that solids get messed up. I haven't had too much trouble with that, but I know it's not foolproof.

-

Here is an example of a messed-up solid, and how to create it. Works every time. I'm astonished that such a basic operation would cause a problem. In my experience, if I work an 8-hour day doing complex mechanical assemblies with SU, at least 1 hour is spent fixing solids. Happened again yesterday, with very simple parts: flat plates or angle iron with holes punched through them. Seems as if every other time I move the holes or change their dimensions, the whole thing goes ka-boom and I have to start over.

Advertisement