Making a sash window profile from image?

-

a recent example of fine work: http://sketchucation.com/forums/viewtopic.php?f=81%26amp;t=55419

-

Or you might have a CAD drawing that you can import as SU edges. If you are not interested in the internal parts, clean up the CAD (section) drawing before or after import to just show the outer skin. Create a face and extrude.

-

@dave r said:

What's the image? Is it the whole window? Is it a line drawing, photo,...? Depending on exactly what info you have, you might be able to import the image for Match Photo and start from there. You might import the image as an image and trace it. Sometimes I'll import an image as an image and just set it up in the background of the model space so I can use it for reference without having to look away from the screen.

Yes Dave, tracing it, how would I do that?

-

Import the image as an image--set that in the Import window. Trace the edges as needed until you close the face. Then you can extrude it. I've shown how to do it in several tutorials. Here's one. I have to run but there are more I can link to later.

-

-

Thank you that was a lot easier and faster than I expected.

-

-

Mike, I'm glad that worked out for you. Out of curiosity, how many segments did you use for the cyma curve in your molding profile?

-

@dave r said:

Mike, I'm glad that worked out for you. Out of curiosity, how many segments did you use for the cyma curve in your molding profile?

I bent the arc twice.

-

-

-

My guess is he used two arcs of default segments therefore the complete curve is 24 segments.

Ooops and a flat in the middle so 25. -

That would be my assumption, too. But you know what assume does.

So 25 segments for that tiny curve is probably about twice what you need for modeling.

-

@dave r said:

That would be my assumption, too. But you know what assume does.

So 25 segments for that tiny curve is probably about twice what you need for modeling.

You've got me lost, I don't have a clue what you are talking about.

-

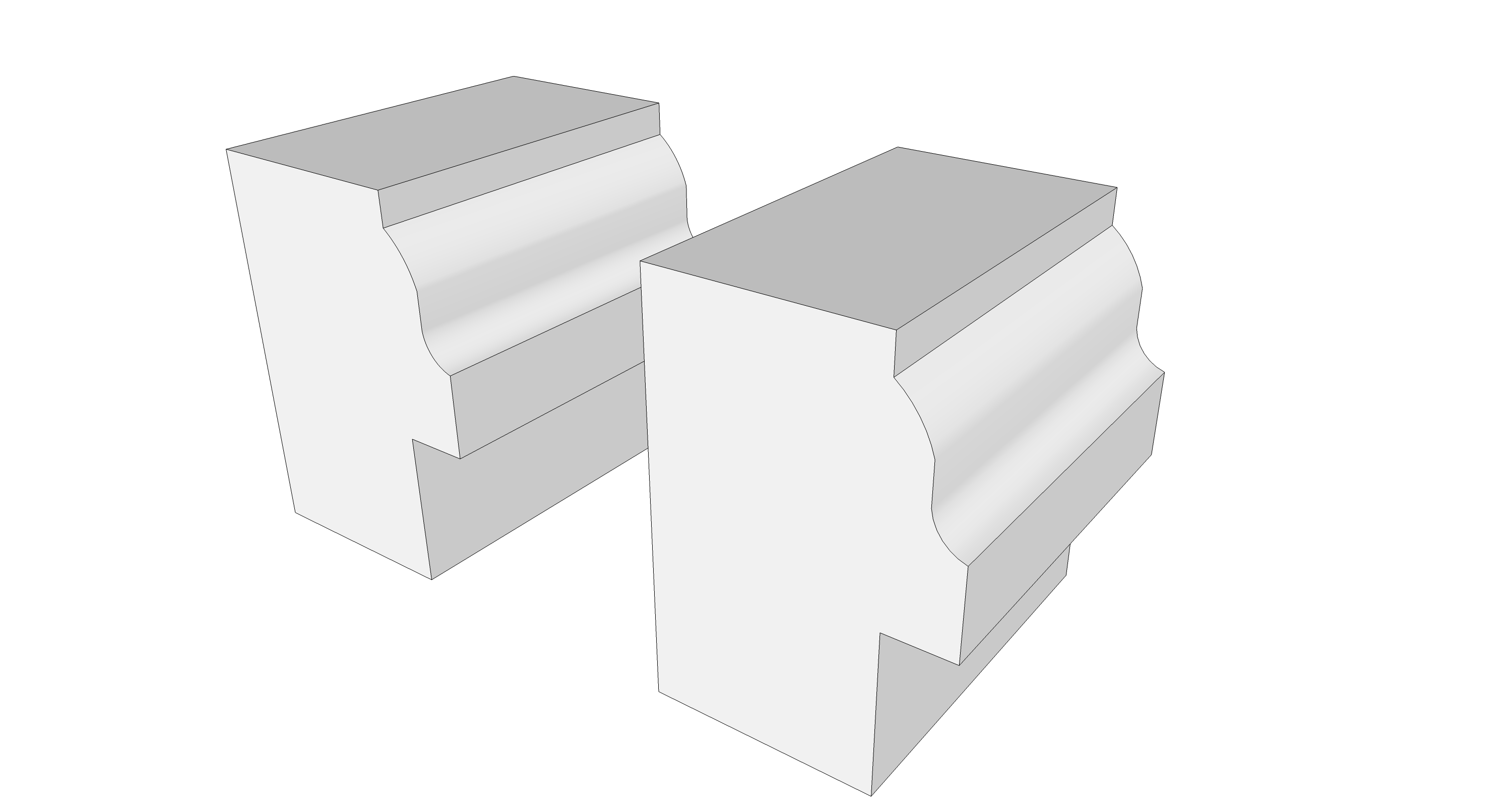

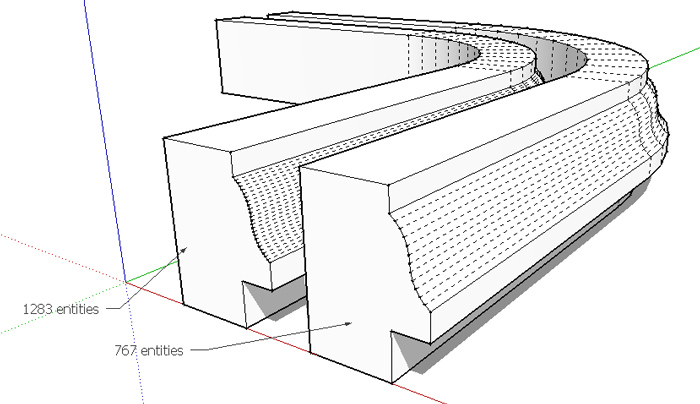

Perhaps you've noticed that SketchUp represents arcs and circles with a series of short line segments. By default an Arc is drawn with 12 segments and a circle with 24. For small arcs such as the ones in your molding profile, 12 segments is overkill. The more segments you have in curves, the more faces you'll have when you extrude the profile. As entity count increases, so does file size. There's little point in using more segments than needed to get the job done. In this image the molding on the left is made with 12 segments in each arc while the one on the right uses only 6. There's no noticeable difference but the one on the right would result in a smaller file because the entity count is lower.

When you use high segment counts for small details, the faces will necessarily be smaller. The small faces can be a problem and result in missing areas.

Save the larger number of sides for things like round table tops and other large curves pieces.

-

You can control the difference if you turn on hidden geometry (view -> hidden geometry).

-

@cotty said:

You can control the difference if you turn on hidden geometry (view -> hidden geometry).

I have turned on hidden geometry but how do I edit to how many segments?

-

You can edit an arc's segment in the "Entity info" window BEFORE you extrude it.

-

@pbacot said:

You can edit an arc's segment in the "Entity info" window BEFORE you extrude it.

In the entity window it says 12 segments but it won't allow me to change this number?

-

Or you can change the number of segments in the VCB box between selecting the tool and starting to draw.

Advertisement

Huh?

Huh?