Re: [Plugin] Quick Lathe v1.2.0 31mar2013

-

Working now, very clever indeed...

john

-

quick lathe sir i installed the plugin but did not appear in tools menu thks

-

Cool one

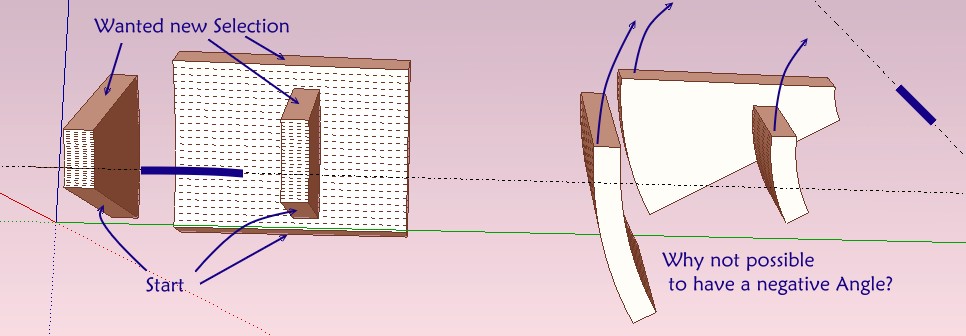

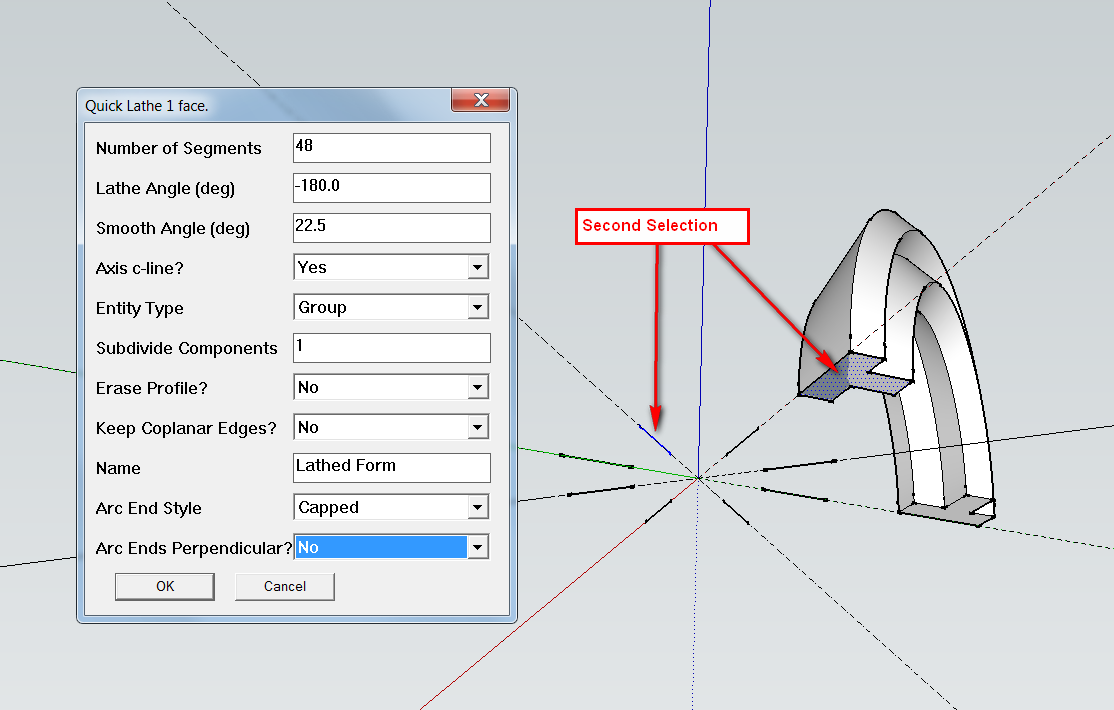

In the case of less 360°

Does it possible to have the End caps as a new selection ?

And a negative angle (or similar) for have a continuous second form etc...!

In this case the "new selection" will make a "return" with the new axe!

( 3 curvated blue arrows wanted ! )

-

Cool!! I don't lathe that often except for coffee, but this one was clever.

A quick question LOCAL_X. Cant You just use X_AXIS ? Since its already available can save you some typing

-

Thanks for the reports and kind words - good to know that it is (mostly!) working!

@chin925 said:

quick lathe sir i installed the plugin but did not appear in tools menu thks

Hi there - there was a damaged file for the download - I replaced this very quickly, but saw that one person downloaded the bad file. Maybe this person was you?

Please try with the newest file (v1.1.1) in the top post - if this one is also broken for you, then let me know, and I will see if I can find the problem.@unknownuser said:

Does it possible to have the End caps as a new selection ?

And a negative angle (or similar) for have a continuous second form etc...!

Hi Pilou - yes, negative angles can be made possible. I avoided negative angles before because it made shapes with a mixture of front/back faces - but with the new code, I will be a able to make this work with a simple transformation.

Selecting "follow-on faces" is difficult at the moment because the end faces can be in different groups - but maybe by moving the original selection it could be done.I think first, I will work on the user interface - already the options are becoming untidy, so I think it needs a proper tool (e.g. rotation arrows for the selection, like in your picture) to make the tool operation more clear.

@jolran said:

A quick question LOCAL_X. Cant You just use X_AXIS ?

He he, a "Doh!" moment! I didn't see the 'X_AXIS' etc. constants before - thanks for the tip, that will be very useful.

-

Yeah, it doesent say so in the API. I think it was TIG who told me last year or so.

-

@unknownuser said:

Selecting "follow-on faces" is difficult at the moment because the end faces can be in different groups - but maybe by moving the original selection it could be done.

In the case of Geometry is enable and not Group or Component !

-

@unknownuser said:

Cool one

In the case of less 360°

Does it possible to have the End caps as a new selection ?

And a negative angle (or similar) for have a continuous second form etc...!

In this case the "new selection" will make a "return" with the new axe!

( 3 curvated blue arrows wanted ! )[attachment=1:1045vhv7]<!-- ia1 -->notpossible.jpg<!-- ia1 -->[/attachment:1045vhv7]

This can be done reversing the selected face(s)

-

@unknownuser said:

This can be done reversing the selected face(s)

Tricky... but that oblige to reverse again the result for have a consistant volume

And as you have several volumes the orient face just work for ONE volume!

So very, very tiedous when have thousand of volumes!!!

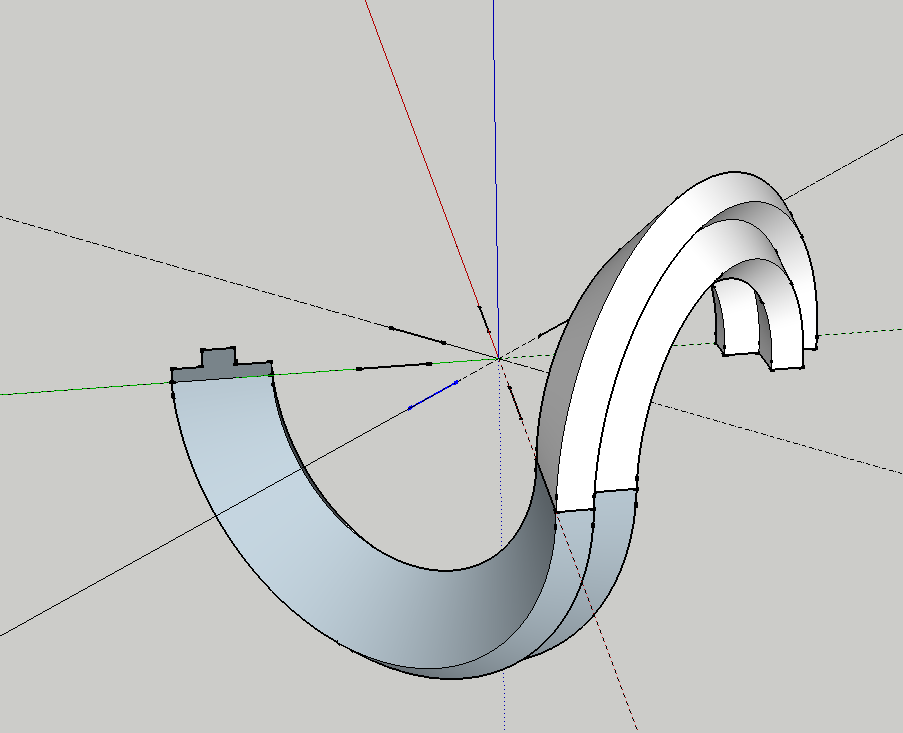

Else very funny when the successive selection will be made! Some sinuous volumes will be made!

(in mode Geometry enable) And think to erase the internal faces!

Bravo for Trogluddite!

And it's a little pity that the axe must be coplanar and not with any orientation!

I don't see not very big differences on the calculation!

Happy easter Eggs!

-

Just a quick note. If the version number in the plugin forum is V1.1.1 than the version number in the rb file should be the same. The version number in the download is V1.1.0. This just makes it easier for multiple upgrades, one can be sure he is operating with the newest version.

And this from a very grateful user of your plugin who is incapable of writing one line of code.

Again thank you for this plugin. Since I model from ACAD/DXF files, I find this a very useful plugin.

Ken

-

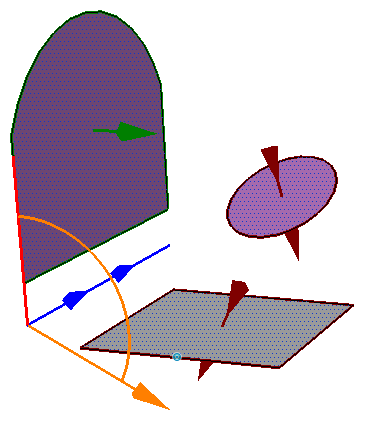

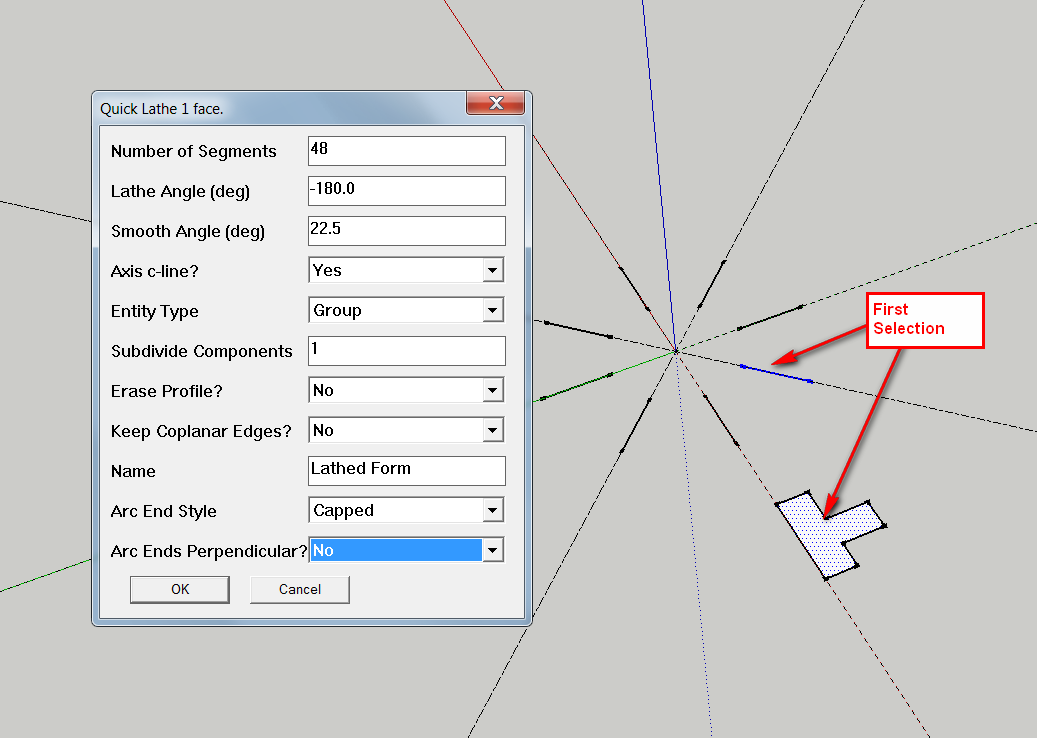

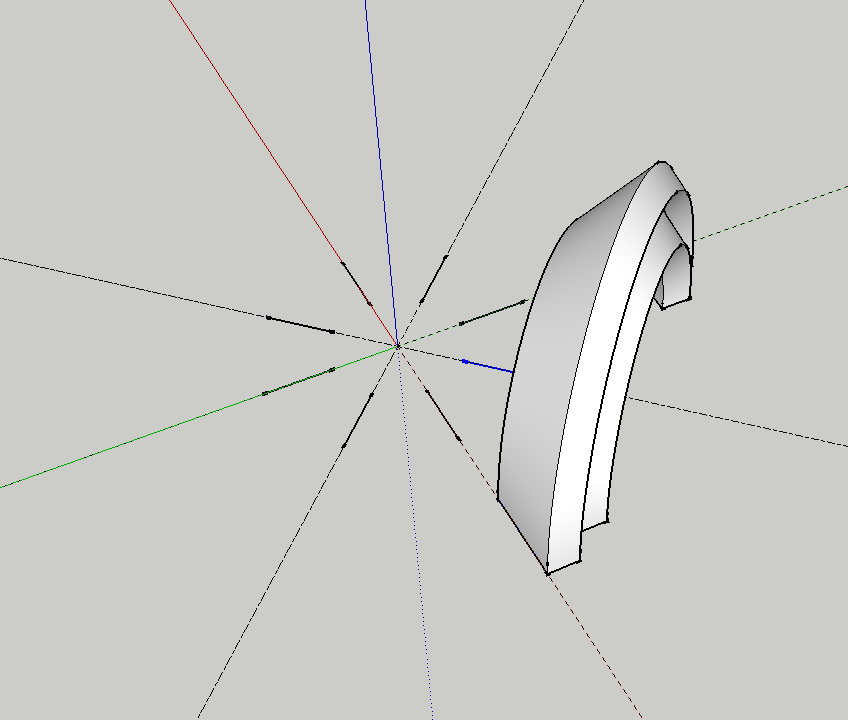

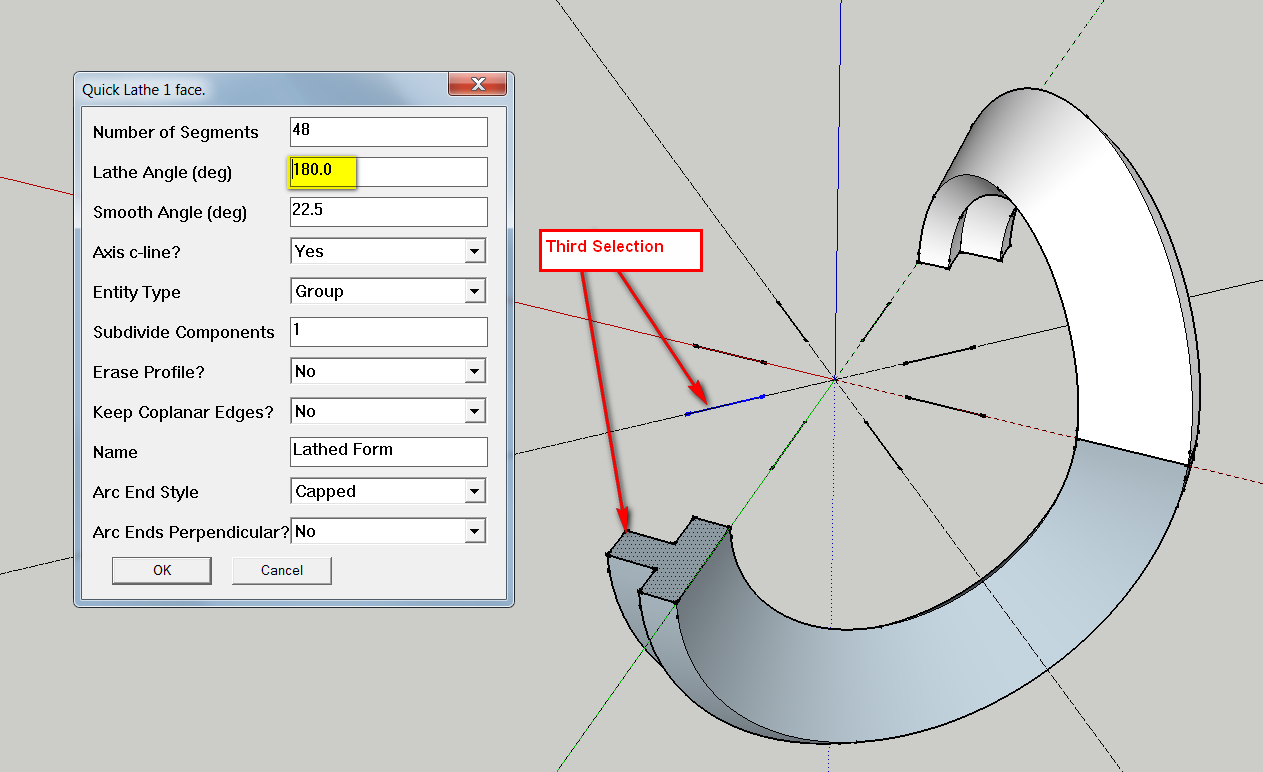

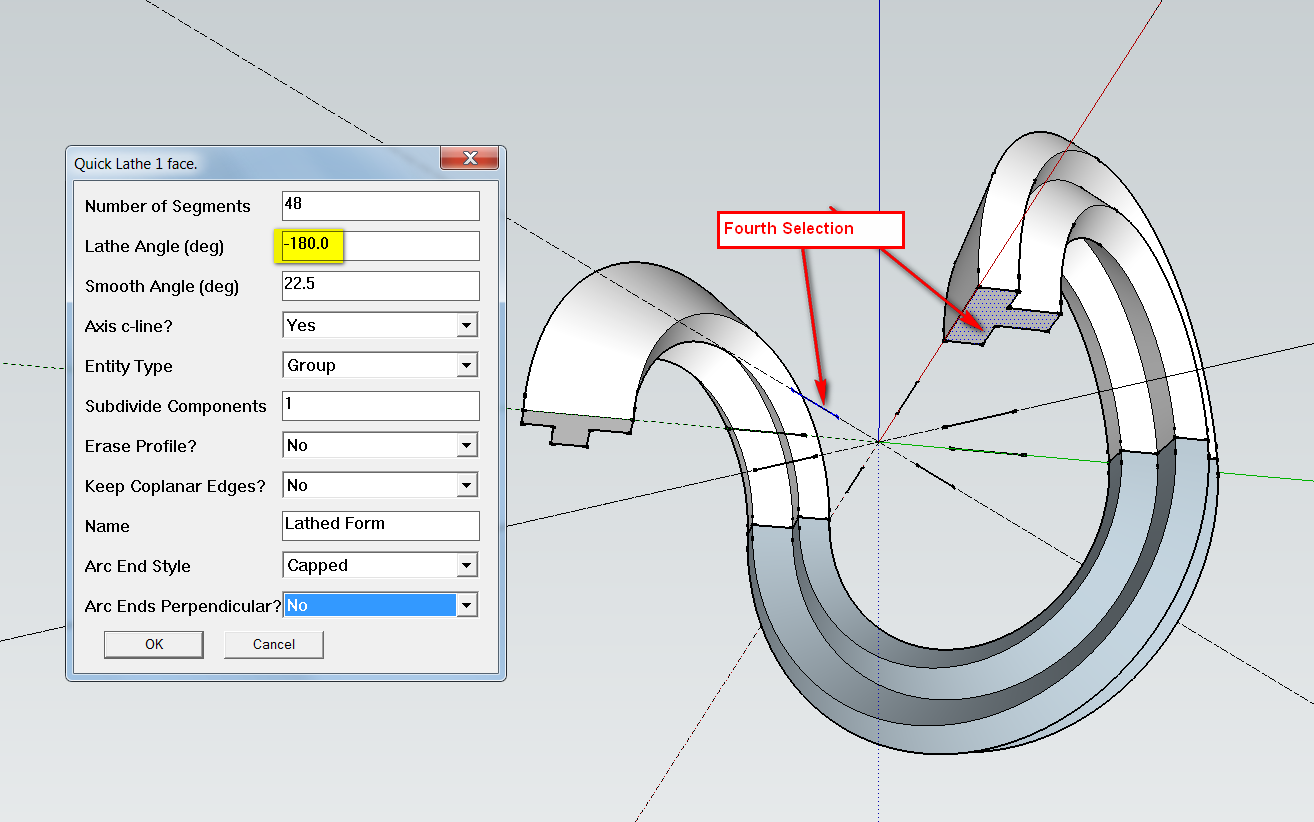

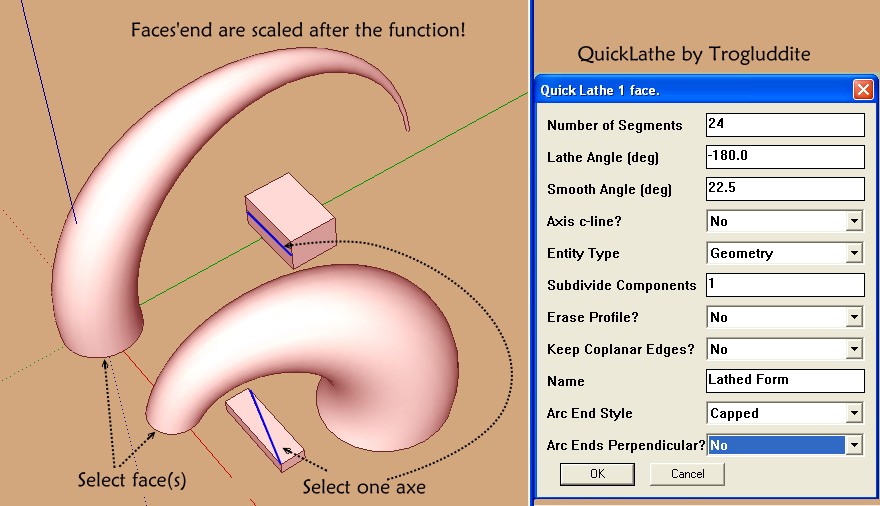

v1.2.0 now available in the top post.

New Stuff...- Negative angles now supported, so you don't need to keep reversing faces.

- Faces don't need to be co-planar - though take care, it means the faces must be triangulated, so much more geometry!

- Face orientation improved - 'inside out' forms should happen much less often.

@unknownuser said:

version number in the rb file should be the same.

Oops, yes, that was a bit naughty. v1.1.1 was a bit of a rush job after I realised that I broke the previous upload by leaving in some de-bugging code.

@Pilou

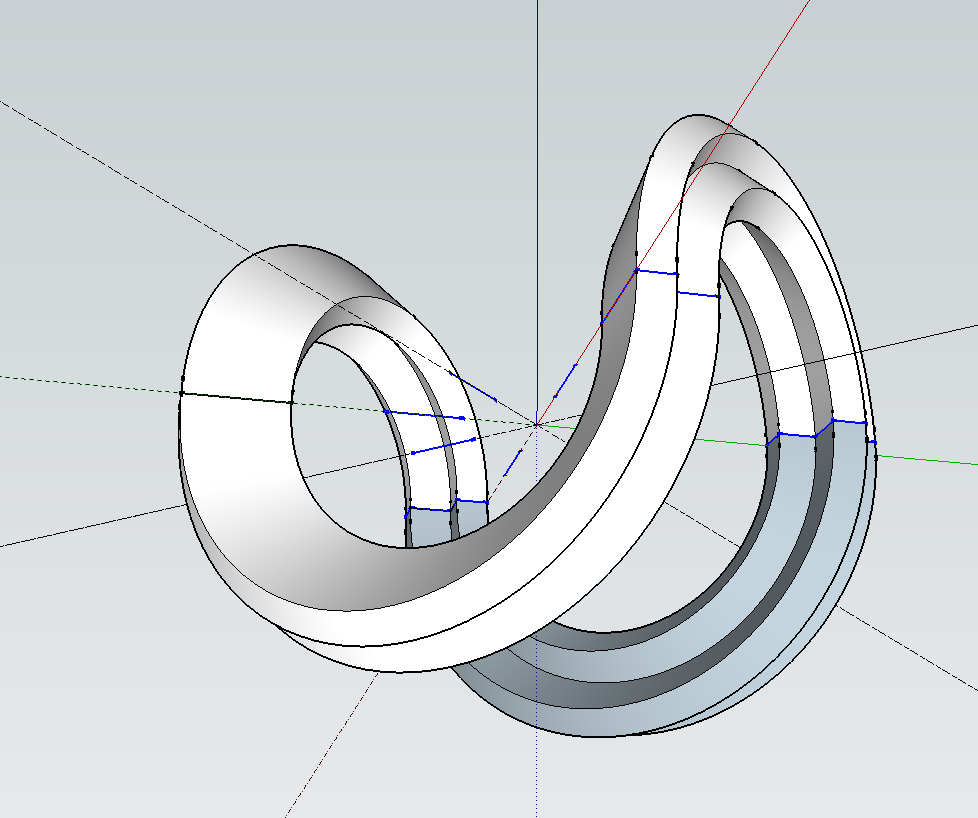

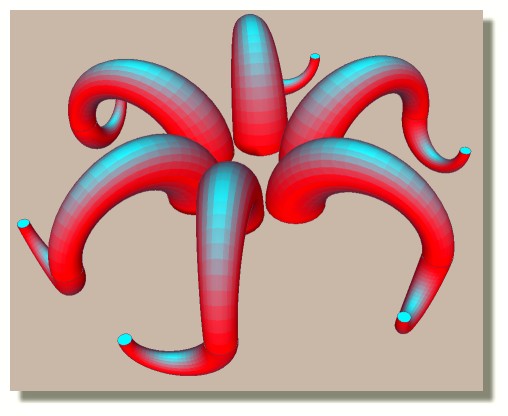

Your funny shapes are very inspiring! May have to re-name the tool though - it's some funny kind of lathe that could do those shapes!

This will probably be the last v1.x update - I'm now working on a whole new user interface to make the settings more visual and easier to work with, and enable a few of the other cool features that people have requested.

Here's a little sneak preview of where I'm at so far...

Features which will almost certainly be included...- Ability to select faces from other contexts (e.g. inside multiple groups/components)

- Axis and angle setting by drawing them with inferences from other geometry.

- On screen direction arrows and colour coding, so you can visualise the settings more easily.

- Quick VCB input of values, and help/hints in the status bar.

Dammit, this Ruby thing is addictive...

-

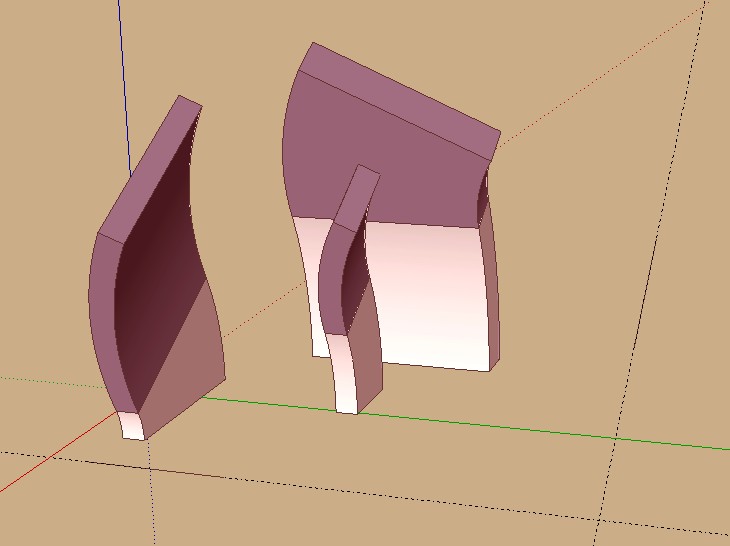

Very cool effort!

Test as soon as possible!

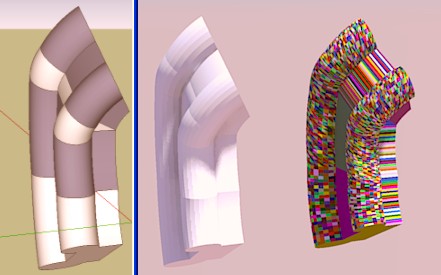

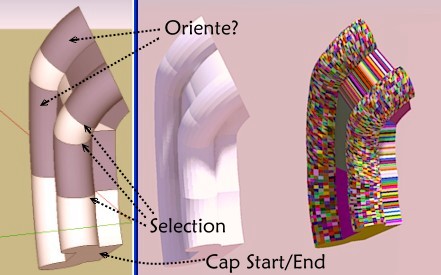

Works fine except unexpected oriente face

Missing automatic Updated Selection between new axis

Must be not a "face" but a profil until the last end face!

So result will be a real "solid"!Suggestion : run the script with only a list of axis in one pass

-

Great plugin. Thanks a lot.

I find it similar to TIG's "extrude edges by lathe" - I like both of them.

My question is - is it possible to add an extra option to "follow me" around a square?

-

Hi,

again a great tool. Right now I have not any specific application but it is fun to experiment with it.

-

@unknownuser said:

Works fine except unexpected oriente face

Hmm, I'll have to have another look at that - seems that the shapes in Charly's pictures also show some 'inside out'.

First, I will check my 'testing' schematic - somehow the shapes I'm using are not showing this problem when I test, so I need to identify some definite problem ones.'Face moving' should come soon - this will be part of a new feature I am making to allow holes in the faces - for making pipes etc.

@smicha said:

I find it similar to TIG's "extrude edges by lathe"

Aha, I wondered when someone would discover my 'inspiration' for my plugin! Indeed, TIG's tools are an indispensable part of my toolbox - in fact, used so often that I made this plugin just to save a few seconds every day doing curve selections...

...and for some practice using Ruby - it will be a long time before I could ever get as good as TIG, ThomThom, Fredo, Dan etc., but I hope to extend this tool for many other types of automatic 'shape creation' eventually.@charly2008 said:

but it is fun to experiment with it

Thanks - and apologies for those inside out sections; they really shouldn't be like that, as Pilou already spotted.

The reactions so far to my first proper 'geometry' Ruby has been amazing - that people can see so much to do with what began life as a tool for knobs and table legs really inspires me to see how far I can push the code...

...but first, I really must get that 'inside out' problem dealt with once and for all!!

-

Believe me this one will be a Ruby.

-

@unknownuser said:

I'm using are not showing this problem when I test, so I need to identify some definite problem ones.

About the oriente face selection (blue / White)

I believe it's just that the face's selection becomes Out/ In at each apply!

(look the Charly's image above) -

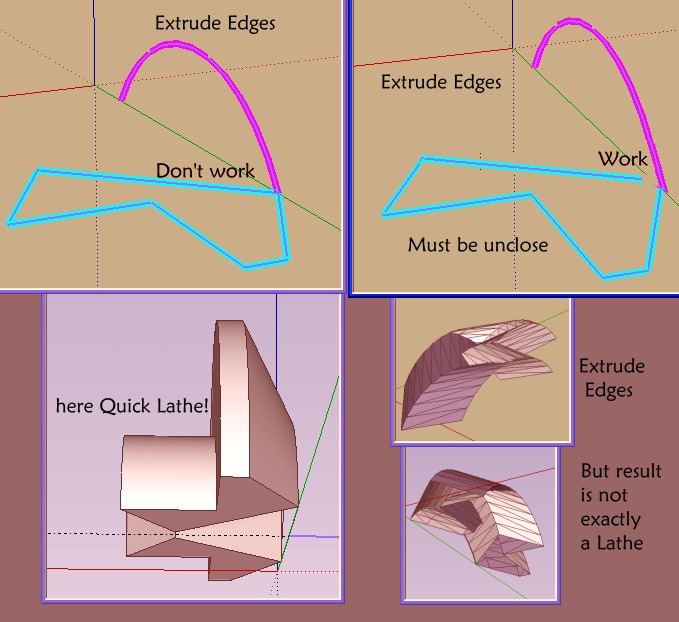

Is this tool ideal for this? Can it also be done with "Edge by Rail" ruby?

-

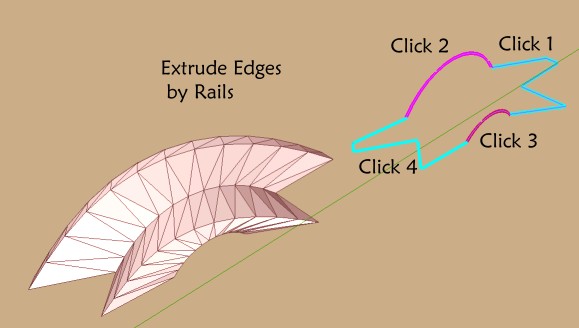

Extrude Edges by Rail by Tig ?

Extrude Edges by Rail works with 2, 3, or 4 curves maxi and has not the same concept!

And can't have a closed profile!

here 2 curves, blue is the profile, Violet is the rail

Must be like this for have similar than a lathe

@unknownuser said:

Is this tool ideal for this? Can it also be done with "Edge by Rail" ruby?

All can be make that but will be not easy with the Extrude by Rails

-

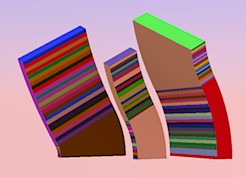

Very funny!

You can select the face after the fonction and Scale or move it(with Alt)!

here Color by Slope by Chris Fullmer

Advertisement