Craftsman Tool Chest

-

So it's been a long time since I've done a woodworking project in SU I've been using all my SU time to expand my Architectural Visualization skills just as a hobby.

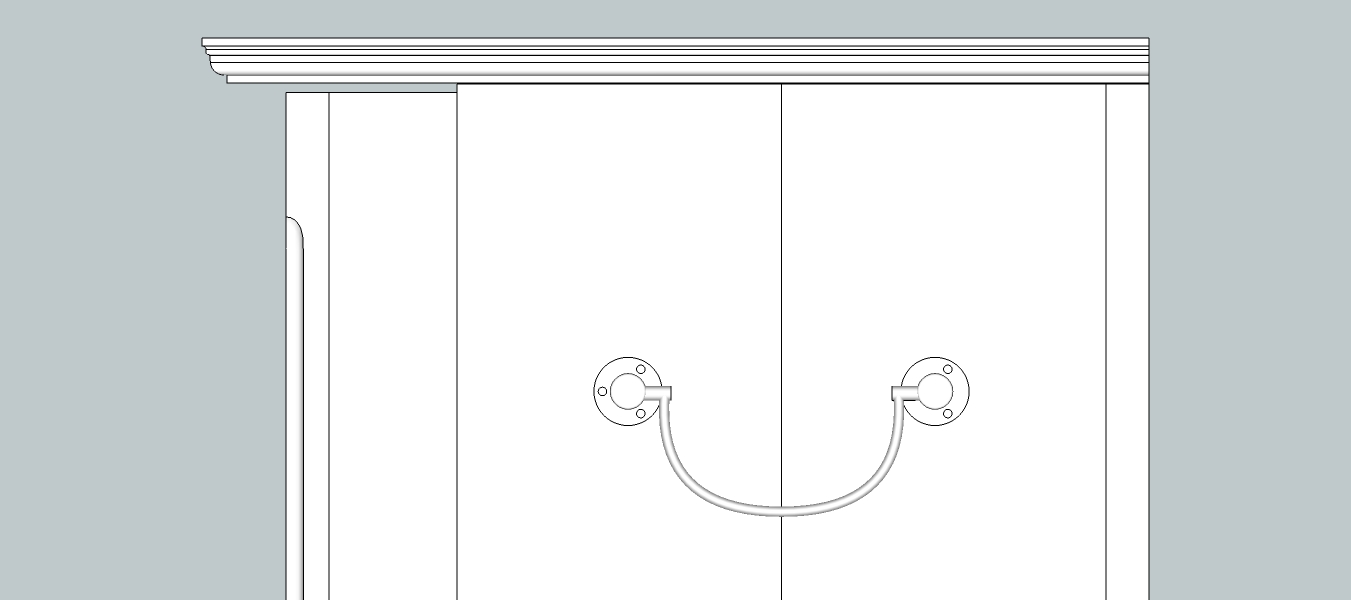

But I've started this project so I can build it some day and hone up on my LO skills. So I thought I would start this as a WIP thread to get some ideas and some C&C. So my first question is in the plan in the magazine that I'm modeling this from the doors have quite a gap at the top to account for wood expansion but I think it's a bit much and kinda well unsightly? the gap is 1/8, which it might expand that much. The front of the doors are a frame and panel constructruction. To get some feed back. Not ready to post screen shot of entire model, another day

Thanks in advance.

-

Walt, I agree the 1/8 in. gap looks unsightly in the 2D side view. It might be that you need that much of a gap though to allow for seasonal movement and still provide clearance for opening the door. You won't see the real one in 2D though so the gap won't look so big.

In the projects I do for my major client, doors and inset drawers are drawn to the dimensions of the opening. We allow the person building the piece to make the determination of how much clearance they need. Since these projects could be built anywhere in the world, the gap would need to be different. In places where there aren't large swings in humidity, the gap can be quite small because there'll be little seasonal movement. In places like Minnesota where we have large changes in humidity throughout the year, a larger gap is needed. The width of the gap at the time of construction needs to be considered based on the current humidity.

You also need to consider the species of wood and how it was cut. If the wood is quarter sawn it won't move as much as it would if it was plain or rift sawn.

Before you build this piece you might go around and measure the gaps on pieces of furniture you have around the house. Consider how those gaps look and work for the piece and make adjustments as needed.

I'm interested in seeing your progress on this.

-

@ Dave I think your right, as usual.

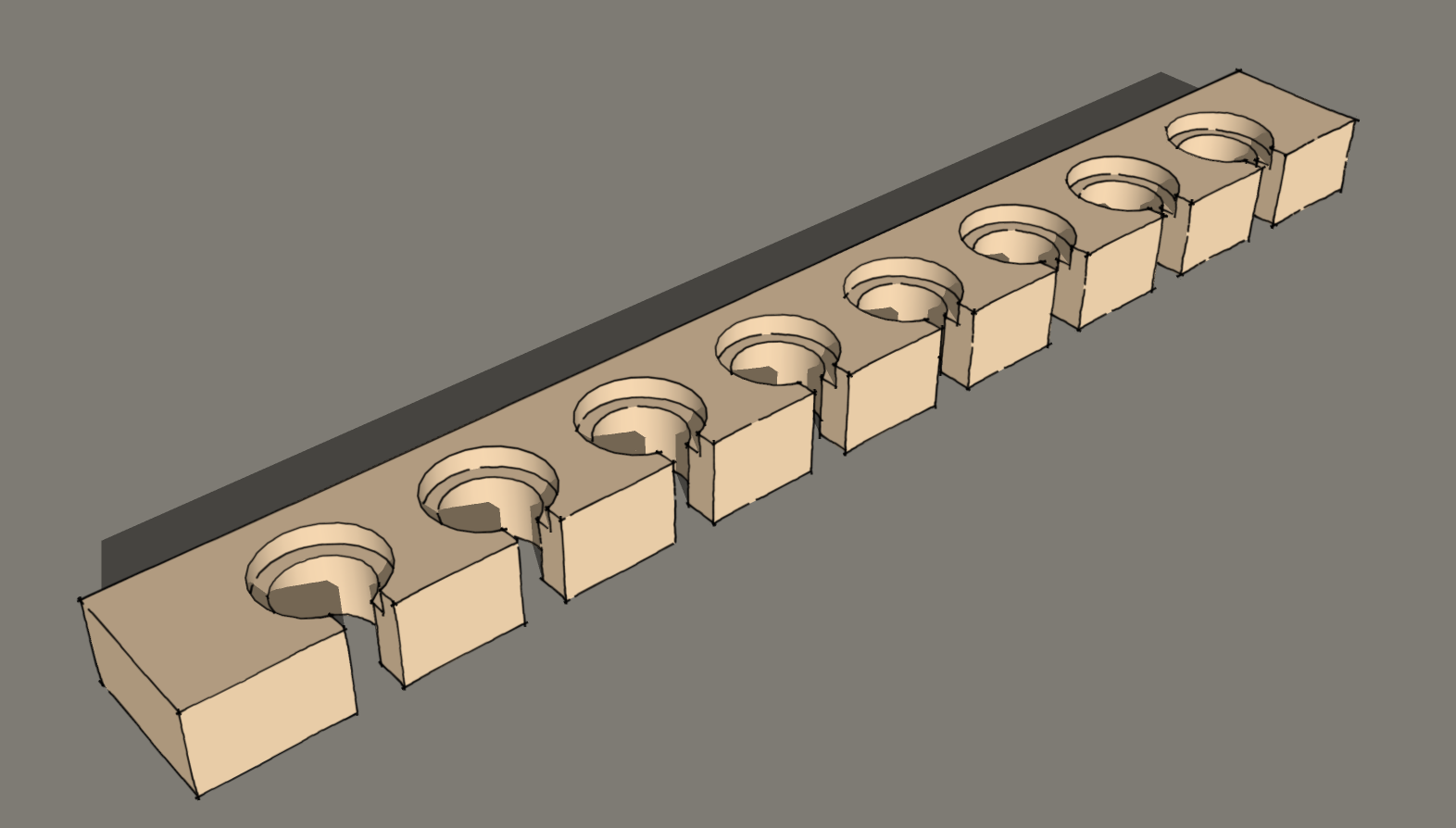

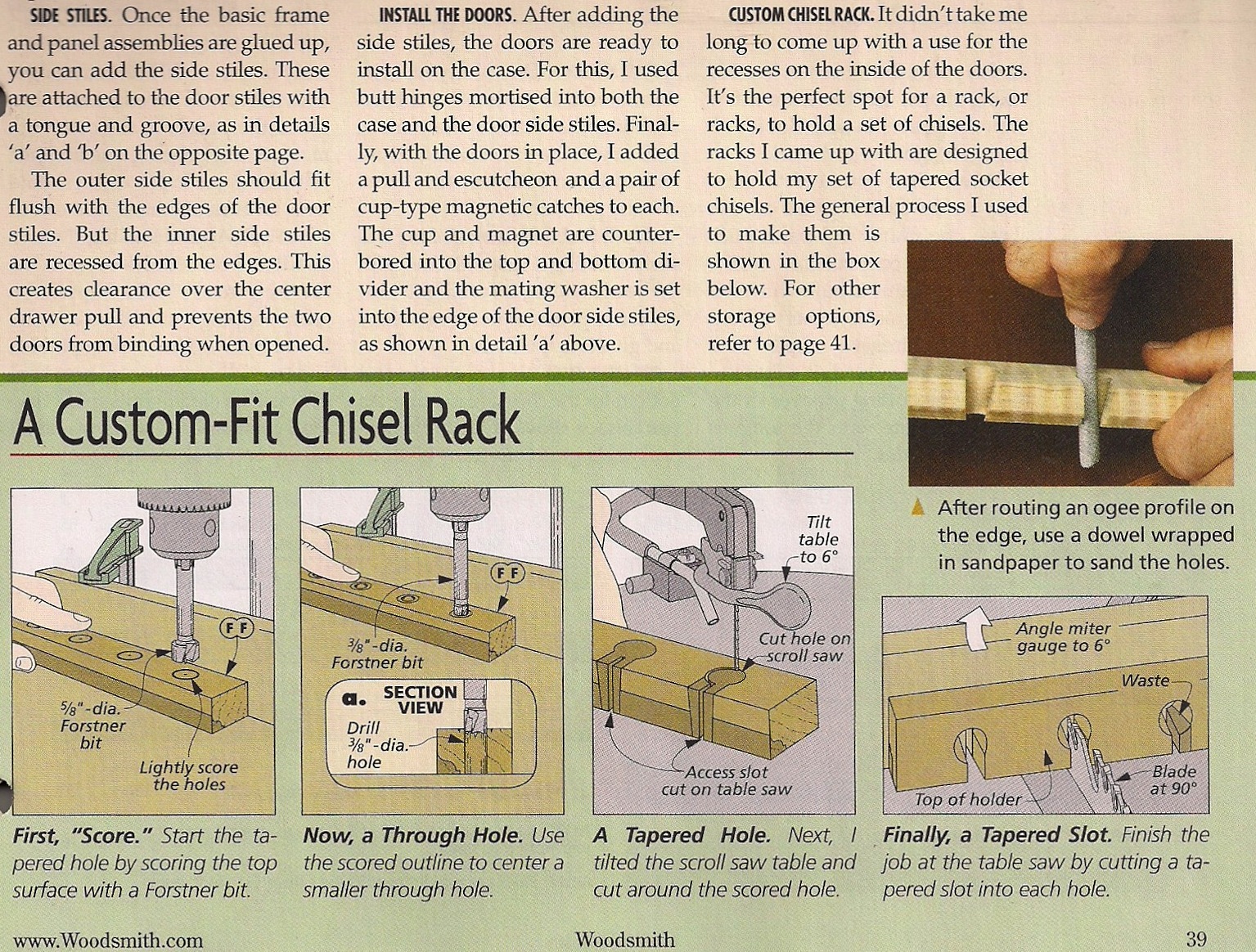

I have a problem doing these chisel racks I want them to have tapered slots. I made the hole with circle tool and push/pull then scale bottom hole 75% about center then draw lines accordingly as you can see in .skp the first one didn't really have a problem but the way they're made they could slip out not what I wanted after I took another look at it so in doing the second one ( rack) the first slot came out fine the way I wanted but in doing the following slots have some strange geometry resulting, even scaling by 1000. Something simple I'm missing I'm sure.

-

I saw in chisel rack.skp some extra lines in the tapered slot. Deleting them resulted in the adjoining faces disappearing but I then traced along the top edges of the slot and the surface appeared to be heeled.

Out of curiosity, how do you plan to create the tapered holes? If I were making chisel holders I would use counterbored holes instead of tapers because I could drill them without special tools. Then I would cut slots with parallel sides using a dado set in the table saw which would be very straightforward.

-

The way you mentioned is the way buit them in my shop probably the best way to go. KISS as my shop teacher always told me.

-

Actually you should make the holder with tapered holes just because I want to see how you do it.

KISS is best.

-

Know a good tool and die man?

-

I used to.

-

I was being facetious by the way

-

I know. There are boring tools for cutting tapered holes. Windsor chair makers and other chair makers for that matter would use them. There's probably one sold by Brian Boggs. Still, a couple of readily available Forstner bits would do the trick.

-

This is a scan of the article so I was just following as close as I could and see if I could do it in SU probably won't build it that way however. But after all it is a Craftsman Tool Chest.

-

Ah. I see. That seems like a lot of work to me. Good SU practice, though.

-

Aw man, I saw the title and thought you were making one of these.

-

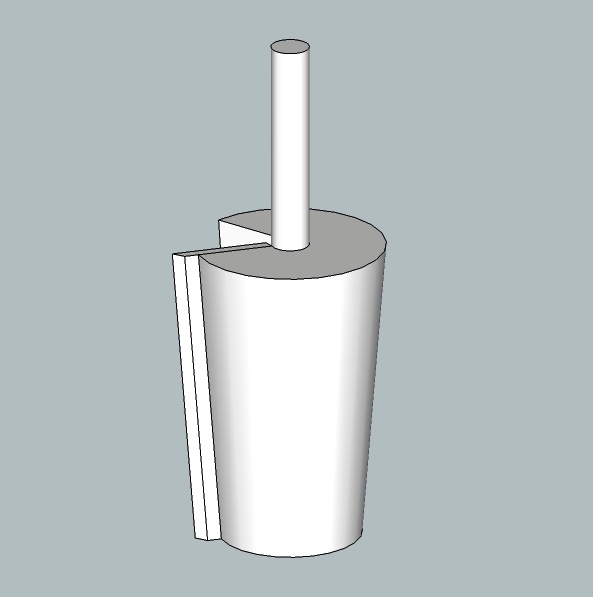

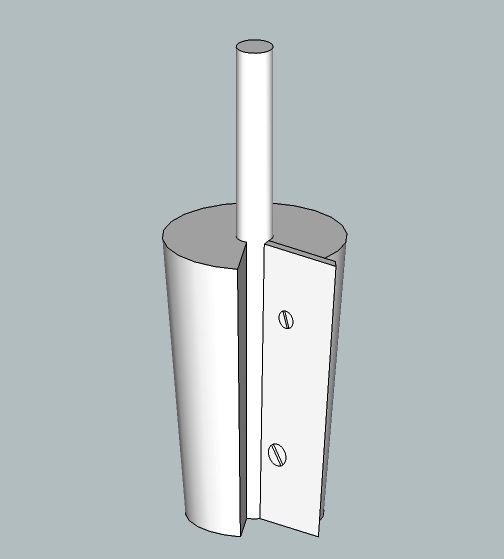

Check it out, it was a lot trouble but it was good practice I used your method in the stopped chamfers tut cut and paste in place and used the solid tools for the first time since I bought SU

-

@ Eric maybe someday. Here's peek I got so far

-

That looks great. I long to make one of those myself someday. My tools are just laying around inside the cart I posted above, not very organized.

If I may, a visual tip with SU. If you turn your back face color to a black or near black you wont' get the white jaggies showing up in your image export.

-

Thanks Eric great suggestion

-

@unknownuser said:

If I may, a visual tip with SU. If you turn your back face color to a black or near black you wont' get the white jaggies showing up in your image export.

Yes, that's a good suggestion. I do that before I make image exports although I use my default green back face color while drawing.

Walt, it looks like a good model. Keep up the good work.

-

Am I missing something? Seems to me that modeling a tapered hole and slot for the chisels is infinitely easier in SketchUp than in real life. In real life, I'd probably use a reamer, like the one Dave R. mentioned that Windsor chair makers use. In SU, I'd make a hole for the smallest diameter, then use the Offset Tool to set the largest diameter on the top face of the board. With the Move/Copy Tool, I'd pull the smaller diameter over to the larger one, tapering the hole. Then, for the slot, I'd turn on X-Ray view and hidden geometry. Trace over hidden geometry lines to mark where the tapered slot falls on the hole, then carry those lines through the board and across the faces. A little erasing, and I'm done. Took longer to type these abbreviated instructions than it did to do the modeling.

dh -

David, I agree with you. Modeling it would be easier than making the real thing. I'd still just use the counterbored holes in real wood.

I can think of several ways to create the tapered hole in SketchUp. Using Cardinal Points is one, Autofold, another.

Advertisement