[Plugin] SPGears

-

%(#FF0000)[3D PRINTERS - USE AT YOUR OWN RISK

%(#FF0000)[3D PRINTERS - USE AT YOUR OWN RISK**This was never intended for use outside of drawn models. However, I appreciate your feedback regarding 3D printing issues and it's all going into the bucket for the (mythical; see "unicorn farting rainbows") version 2. So far, these are known issues with the plug-in:

-

Not completely accurate - check fit (in SketchUp) before you print!

-

Not smooth - Sketchup does not use "true" arcs

As of Nov. 2014, I am actively (though slowly) working on version 2. I was hoping it would only need some tweaks, but to fix the accuracy problems it's turning into a ground-up rewrite. Probably not a bad thing, especially since SU 2015 and the unofficial SP v3.5 update were recently released.**]

Copyright 2012, by Mark Jason Grundman

Permission to use, copy, modify, and distribute this software for

any purpose and without fee is hereby granted, provided that the

above copyright notice appear in all copies.

THIS SOFTWARE IS PROVIDED "AS IS" AND WITHOUT ANY EXPRESS

OR IMPLIED WARRANTIES, INCLUDING, WITHOUT LIMITATION, THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE.

#---------------------------------------------------------------

Name : SPGears_mjg.rb

Description : This file draws various types of gears with involute

tooth profiles

Menu Item : Plugins -> SPGears

Context Menu: NONE

Date : 12-27-2016

Version: 1.2

This is a really great tool for creating custom gears in both static and SketchyPhysics (SP) models. For SP users, gears are 'ready-made' objects, so you only need to add a hinge or motor joint and you're done. *** Note: Gears are designed to work with SP, but the tool does not require SP to work in static models.* This tool works well for drawing gears in static model too!

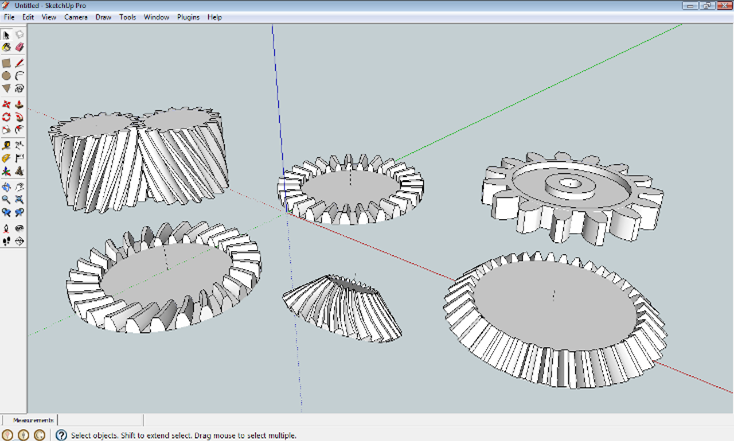

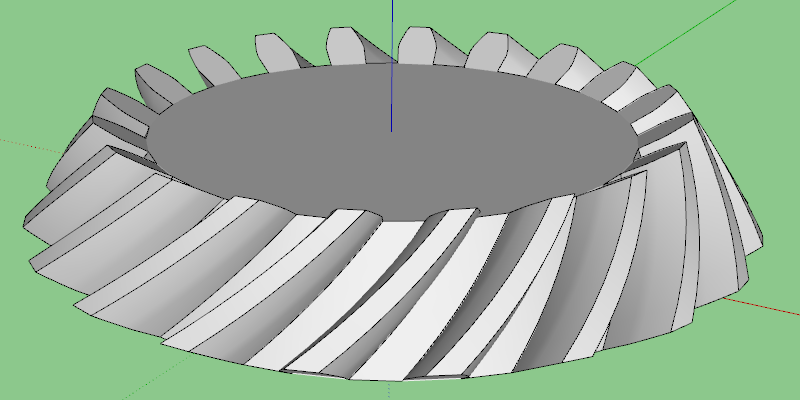

This first version of SPGears will create spur, helical, bevel, and beveled helical gears with involute tooth profiles. It is pretty fast and parameters allow for a huge range of custom dimensions. It's far from "finished", but as my first attempt at a plugin, it's pretty cool, and it works. Hope you find it useful.

This was written using Sketchup8 and has not been tested with previous versions of SU.

Already planned improvements for next version:

- additional gear styles (rack, worm, and internal ring)

- improve calculations and accuracy

- web dialog UI (additional input params and auto-calculations)

- gear properties/specs dialog via context menu

- improved validation

Coming soon: Video of gears in action, using SketchyPhysics

Helpful tips:

- Helical direction is determined by +/- angles. (pos.= CCW / neg.= CW)

- The core is a solid cylinder/cone, in a separate group, with a construction line on the center axis. You can easily add circles and use push/pull tool to add hub/rim details.

- Beveled helicals are not very precise (yet), so getting them to line up with mating gears may not work.

- Pitch radius is about the midpoint on the gear teeth. Outside diameter (at the gear tips) is actually larger.

[v1.2 - 12/17/2016 revisions and additions

- all measurements default to model units and can be specified using standard unit suffixes (such as "mm" for you folks that have been asking for that option)

- added root fillets

- added rim and web to base profile

- modified involute calculations to maintain curve detail as size decreases

Don't forget to uninstall previous versions!](/uploads/imported_attachments/fSp1_SPGears_mjg_v1.2.zip)

-

-

Welcome to the forum! Thanks for contributing.

It'd be nice if you could include a screenshot or two of the plugin in action and what it does. When people scan quickly through to find a plugin it's more likely they'll stop and investigate if there's some imagery. Very visual people here you know.

Sidenote - I scanned through the source code and saw this on line 200:

t4 = Geom::Transformation.rotation [0,0,0], Z_AXIS, (2 * Math::PI * n / @teeth)The

Numericclass in SketchUp has been extended to make it easier to convert between degrees and radians for you: https://developers.google.com/sketchup/docs/ourdoc/numeric You rarely need to use PI yourself. -

Welcome, and thanks for sharing.

No joy getting your plugin working so far, I'm sorry to say - instant Bug Splat.

Does it require Sketchy Physics in order to draw the gears? If so, a non SP version purely for drawing them would be really nice. -

Have you a little Youtube video of this plugin ?

-

Hello Again,

Apologies for my earlier bug report being rather scanty - had to dash out of the office mid-way through posting. So here is some hopefully more useful detail...The dialogue box appears OK, and I am able to enter new values. The 'splat' happens as soon as I press the 'OK' button - too quickly to see if there are any messages in the Ruby console.

I checked whether it was a clash with some other 'rogue' plugin by temporarily clearing my plugins folder so that 'SPGears' was the only one available. I've also tried using alternative units and having some/none other geometry in the SU session. Sadly, a bug splay every time.I'm using SU Pro v8 (latest maintenance release to 8.0.14346) on WinXP, and my PC is nice and stable with my usual plugin collection.

Got my fingers crossed this can be fixed without too much trouble - I've been after a simple, versatile way to draw gears for a while, and your screenshots have really whetted by appetite! -

Trog,

Sorry you're having difficulty. I did find an error when adding the tool to the plugins menu, but the issue you're seeing sounds different. I've reposted the zip file with the correction that I found, so try it and let me know what happens. If you still get the bug splat before the console can report any errors, check the splat details to see if it provides any clues. Thanks! -

Having written a rather primitive gear plugin of my own, I was very interested in seeing how you did yours. Very nice I must say. I had no problem loading and running the plugin. My only question/request is, given the examples in the screenshot, what parameter values did you enter to achieve the various gears?

-

NICE, real nice!

Works on Mac BTW ( I commented the logtofile method because it was clearly window and specific, so I don't know if that would crash if I didn't, didn't try, but with it commented, no problem)

Thanks for this nice plugin!

-

+100000000000000000000000000000000000000000000000000000

I couldn't, just couldn't Draw twisted gears myself. No doubt, this is an awesome plug. THanks!!!!

-

Hi Again,

re: Bug Report

I've now checked out the plugin on a couple of other machines in the office - all working perfectly; an excellent piece of Rubying!

The alternative machines all have a clone of the plugin folder on the troublesome one - so it looks to be a problem with the OS or SU installation on my main machine. The only bugsplat dump that I managed to find was just a mess of raw binary - but if you have the ability to decode it, I can post it up if you think it may be useful.

Thanks for your efforts so far - but as I seem to be the only user having trouble, please don't expend too much effort on this lone bug report. As it happens, our IT team are just setting me up with a new PC - so with any luck, I'll get to use your plugin to make some funky gear trains in a day or two anyway! -

@trogluddite said:

...so it looks to be a problem with the OS or SU installation on my main machine.

Trog,

Thanks for the update. I'm having similar issues on my end. My 2 yr old notebook (I used to write the code) was giving my fits with the animation. When I tried it on my 12 yr old desktop, animation was smooth and ran for 800+ frames before crappping out. That's why I took down the warning about animation issues. I think my problem is too many background apps taxing the processors, but I haven't tested it yet. Anyway, glad to hear its working on other machines. -

@sdmitch said:

...what parameter values did you enter to achieve the various gears?

For the larger diameter samples, I used the default 10" radius and the smaller ones are between 5" and 7" radius (don't recall, exactly). The beveled and flat gears are different bevel angles of 45 and 90 degrees, respectively. The helicals are all 30 degrees, except the mate to the long pair which is -30 degrees. The bevel can be set to negative values, putting the teeth on the interior, but the results are less than satisfactory. I will be adding true "internal" gears in version 2. I also need to redo the beveled helical since the current params result in a semi-hypoid shape.

-

Thanks for this plugin. I'm a longtime user of gear.3.rb and this looks like an upgrade.

Addition of worm gear function would be great. I'm struggling with getting a parametric worm gear in sketchup which I use to export to .stl and print on a 3D printer for various projects. The hard part (as discussed in this thingiverse model: http://www.thingiverse.com/thing:9827) is the worm gear part.

Anyway, thanks again,

Brendan -

Hi Again,

Just a little follow up on that old bug report.

The IT guys finally got my new machine set up - and, oh no, the plugin was still having problems...

...until I went into the BIOS and increased MoBo GPU RAM to 500MB instead of the paltry 32MB allocated by default (had to use the MoBo, as the supposedly nice graphics card they put in couldn't even handle the SU view port!).

It now strikes me that this might have been the problem with the old PC - that also was using the MoBo graphics, and can't have have 500MB GPU space because the whole machine only had 1GB installed!

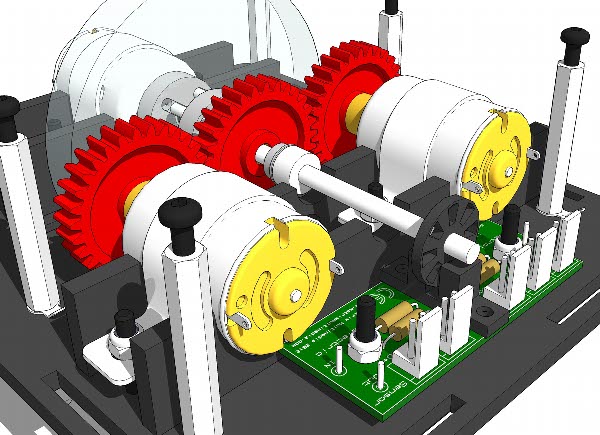

Here's a piccy of the first completed project...

...suffice to say, the boss was well pleased, especially as upcoming projects will require much more complex gear trains than this.Many thanks for your excellent tool,

Trog -

Thank you, the gears are perfect for use in sketchyphysics

-

First of all a huge thank you!

I've been looking for a way to have custom gears made for a while until I found this plugin. Decided to try it out by drawing a pair of helical beveled gears and had them 3d-printed. As far as I can tell, the gears mesh beautifully and work axactly as they should!

I just have one small wish: It would be great if the center guide that is created for the (bevel) gears would extend all the way to tip of the pitch cone. It would speed up aligning the gears in sketchup significantly. -

oh my god thank you

-

Found a small bug:

Regardless of the unit of measure of pitch radius, the face width is always measured in inches, makes it a little harder to make gears of certain widths when using the metric system. -

I am brand new to this Plugin and Sketchup. I had no problems in principle with this plugin - I'm using Win 7. My aim is to create gcode and so far I have played with the plugin gear.3.rb to make the gears and the Phlatboyz plugin for gcode. However, I was dissapointed to find that gear.3.rb uses all straightline segments which to cut a long story short, makes the code too long for our mill. I was hoping for arcs in this plugin but it too uses straight lines. I'd love arcs to be a feature of this plugin.

Cheers

-

Sweeet Plugin.

Advertisement