My first bit of furniture

-

@roger said:

What was the CAD tweak? The project seems so straight forward, I can't imagine what CAD would have added.

Hi Roger. The cad tweak was to resolve subtle compound curves fed to the CNC. It required 180 seperate parts hand nested with a tolerence of <0.1mm, 681 parts in total. I use cad on a daily basis and it took 60 hrs cad time. The cad was also used for structural analysis modeling. SU was only used as a visualisation tool.

Cheers, and happy New Year!

-

@steved said:

@sepo said:

1.were you planning to use plywood or solid wood? solid wood would be quite expensive and bending of each element somewhat unpredictable.

2.how would you laminate? I suggest that glue would not be enough in itself. you would need some tension rods.

3.in any case the piece would be quite heavy.. so you might consider missing every other lamination to reduce the weight.

4.last render looks quite good

Hi Sepo, you missunderstood The piece has been produced as is shown in the last (poor) photo. It is a vertical lamination. It is very light indeed (24kg) so lightening it is not an issue. When using a crosslinked or even standard pva the joint is beyond the spec of the laminate itself

cheers and thanks

Ah.. OK... I did understand it is vertical lamination. 24kg is not lightweight by any standard. On contrary it is lot of weight to move around. So what was it made of... ply or solid wood?

-

Furniture grade ply.

-

hi steved,

your piece of furniture looks just amazing , great desing a superb processing.

, great desing a superb processing.I have a few questions.

- did you design it yourself? => where you get proportions of your deckchair?

- how did you manufactured it? CNC router or something else (e.g. water cutting machine)?

- i can see a lot of waste from a plywood boards - am i right?

- what is wood preservation treatment in this case?

- how much is it?

- the renders doesn't looks good. have you tried Vray for SU?

- do you share your models in 3dwarehouse?

thank you for reply in advance.

happy new year .

. -

Great seeing a project from start to finish.

Good luck in Sydney

-

@jarynzlesa said:

hi steved,

your piece of furniture looks just amazing , great desing a superb processing.

, great desing a superb processing.I have a few questions.

- did you design it yourself? => where you get proportions of your deckchair?

- how did you manufactured it? CNC router or something else (e.g. water cutting machine)?

- i can see a lot of waste from a plywood boards - am i right?

- what is wood preservation treatment in this case?

- how much is it?

- the renders doesn't looks good. have you tried Vray for SU?

- do you share your models in 3dwarehouse?

thank you for reply in advance.

happy new year .

.Hi Jaryn, thank you for the compliments!

- Yes I designed It from scratch (my discipline is Industrial design) the start point was solving an engineering/ Architectural problem for another design concept. This started off as a test piece to prove the engineering before attempting a more complex piece, but it got out of hand, LOL. Proportions were initially hybrid thinking intuitively compromising, between engineering, ergonomics, and aesthetics. The tweaking after that was VERY comprehensive and very resolved. It is not a deck chair though, it is an interior recliner. I have had one conversation with only one, high end professional who suggested that I should only produce 1000 of consecutively numbered and charge a premium , in the design/art niche. I am still thinking about that.

- CNC routing, water cutting ply will cause warpage the very enemy of this process. This piece was produced in a humidity controlled environment.

- Sheet wastage is quite moderate, due to very, very careful 'hand nesting' in CAD(Why they need to be hand nested as opposed to auto-nested is a lo........ng story for another day)

- They are for an indoor minimalist environment, they are not for mass production and are very expensive to reproduce, so I do not see them lying around poolside. However academically marine grade ply would be OK.

- Big question?

- Yeh the renders aren’t fantastic but they do show the form very well for pre production for 'aesthetic critique' now I can take images of the real thing.

- No the design is registered but allowing use of the model at this stage would be premature. Will re-visit the question soon though.

The piece is about to be shipped to Sydney in about two weeks as it was short listed for final judging, in the 'Edge furniture design competition' at the international furniture fair where it will be exhibited. And I am interested in some sensitive opinions for options regarding the upholstered component. I would appreciate input, if you would be interested in voicing an opinion (I can present the options to you, for comment) please feel free to IM me.

Hope your questions were adequately answered, and thank you for your interest, Jayrn, and a very happy and fulfilling year to you as well!

Cheers

Stephen

-

Lets start with fact,your product is perfect and everybody loves it

.

.

I like your artefact and than i would like to know something about it.

questions:- did you use golden section rule for design your artefact?

- second question

@steved said:

- Sheet wastage is quite moderate, due to very, very careful 'hand nesting' in CAD(Why they need to be hand nested as opposed to auto-nested is a lo........ng story for another day)

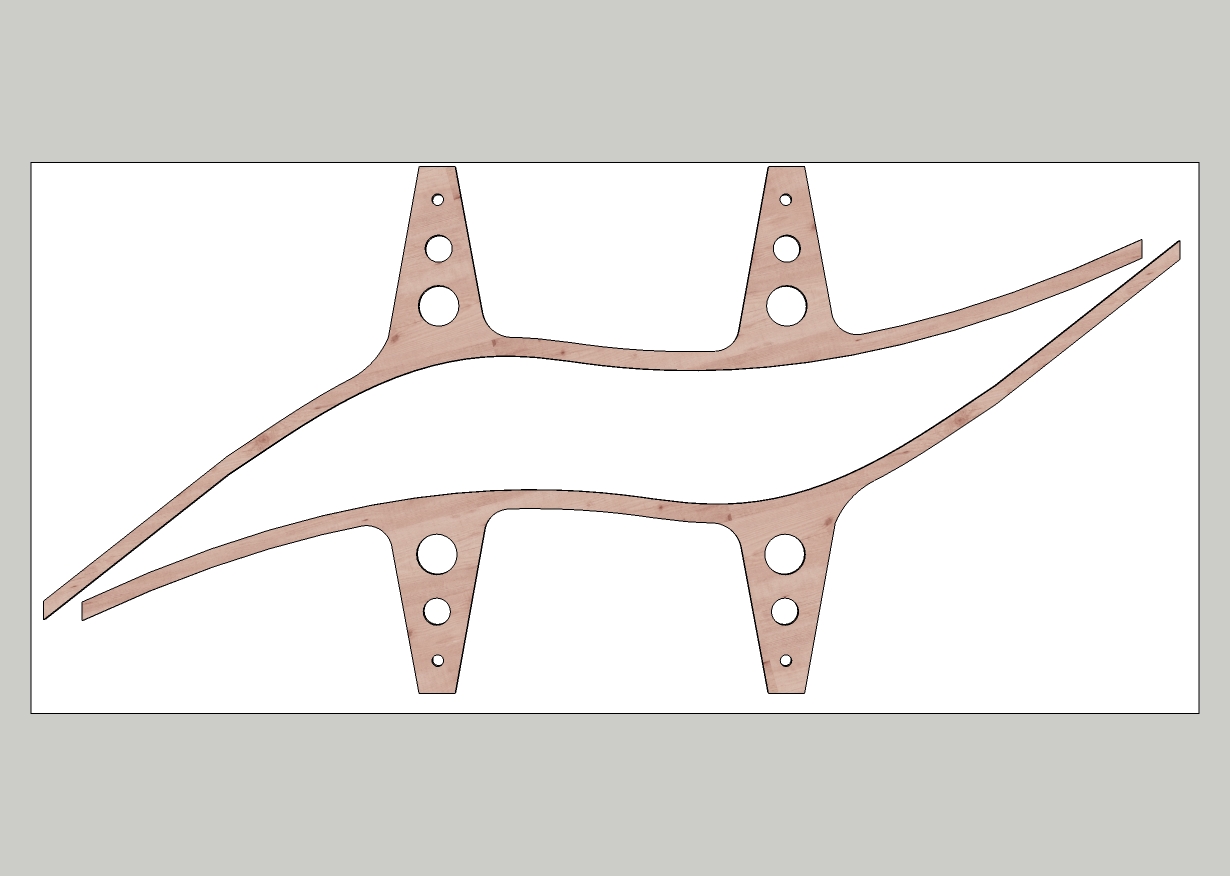

does the sheet look like this? or i am completely wrong?

3. question and suggestion

i know design process of new product from its start to end, and i know that is very tough and time consuming process (sometimes it could be frustrating experience) and then please take these sketches as a questions at the begining of the design process than a suggestions of modification.@steved said:

- Yes I designed It from scratch (my discipline is Industrial design) the start point was solving an engineering/ Architectural problem for another design concept. This started off as a test piece to prove the engineering before attempting a more complex piece, but it got out of hand, LOL. Proportions were initially hybrid thinking intuitively compromising, between engineering, ergonomics, and aesthetics. The tweaking after that was VERY comprehensive and very resolved. It is not a deck chair though, it is an interior recliner. I have had one conversation with only one, high end professional who suggested that I should only produce 1000 of consecutively numbered and charge a premium , in the design/art niche. I am still thinking about that.

Stephen

@steved said:

It is a vertical lamination. It is very light indeed (24kg) so lightening it is not an issue.

cheers and thanks3a.i made a quick sketch and quick renders that shows recliner's modification (no lamination process and half weight). did you think that your recliner could look like this at the beginning of your desing process? i think that production is cheaper than laminated version (less material, less work, less machines)

3b. do you think that this could work?

4. question@steved said:

- CNC routing, water cutting ply will cause warpage the very enemy of this process. This piece was produced in a humidity controlled environment.

what do think if you cut it on laser instead of on CNC router? you get closed surface but with srange color.@steved said:

The piece is about to be shipped to Sydney in about two weeks as it was short listed for final judging, in the 'Edge furniture design competition' at the international furniture fair where it will be exhibited.

good luck in Sydney

.

.@steved said:

And I am interested in some sensitive opinions for options regarding the upholstered component. I would appreciate input, if you would be interested in voicing an opinion (I can present the options to you, for comment)

i am looking forward to it. i work on deckchair and i have same problem

.

.last question please

@steved said:feel free to IM me

- what is IM?

good luck on february in Syndey

.

. -

No possibility to make a sort of rocking chair?

-

@jarynzlesa said:

Lets start with fact,your product is perfect and everybody loves it

.

.

I like your artefact and than i would like to know something about it.

questions:- did you use golden section rule for design your artefact?

- second question

@steved said:

- Sheet wastage is quite moderate, due to very, very careful 'hand nesting' in CAD(Why they need to be hand nested as opposed to auto-nested is a lo........ng story for another day)

does the sheet look like this? or i am completely wrong?

[attachment=0:3rjzjsxb]<!-- ia0 -->sheet waste.jpg<!-- ia0 -->[/attachment:3rjzjsxb]

3. question and suggestion

i know design process of new product from its start to end, and i know that is very tough and time consuming process (sometimes it could be frustrating experience) and then please take these sketches as a questions at the begining of the design process than a suggestions of modification.@steved said:

- Yes I designed It from scratch (my discipline is Industrial design) the start point was solving an engineering/ Architectural problem for another design concept. This started off as a test piece to prove the engineering before attempting a more complex piece, but it got out of hand, LOL. Proportions were initially hybrid thinking intuitively compromising, between engineering, ergonomics, and aesthetics. The tweaking after that was VERY comprehensive and very resolved. It is not a deck chair though, it is an interior recliner. I have had one conversation with only one, high end professional who suggested that I should only produce 1000 of consecutively numbered and charge a premium , in the design/art niche. I am still thinking about that.

Stephen

@steved said:

It is a vertical lamination. It is very light indeed (24kg) so lightening it is not an issue.

cheers and thanks3a.i made a quick sketch and quick renders that shows recliner's modification (no lamination process and half weight). did you think that your recliner could look like this at the beginning of your desing process? i think that production is cheaper than laminated version (less material, less work, less machines)

3b. do you think that this could work?

[attachment=2:3rjzjsxb]<!-- ia2 -->recliner_uprav.jpg<!-- ia2 -->[/attachment:3rjzjsxb]

[attachment=1:3rjzjsxb]<!-- ia1 -->recliner_uprav_scena_2.jpg<!-- ia1 -->[/attachment:3rjzjsxb]

4. question@steved said:

- CNC routing, water cutting ply will cause warpage the very enemy of this process. This piece was produced in a humidity controlled environment.

what do think if you cut it on laser instead of on CNC router? you get closed surface but with srange color.@steved said:

The piece is about to be shipped to Sydney in about two weeks as it was short listed for final judging, in the 'Edge furniture design competition' at the international furniture fair where it will be exhibited.

good luck in Sydney

.

.@steved said:

And I am interested in some sensitive opinions for options regarding the upholstered component. I would appreciate input, if you would be interested in voicing an opinion (I can present the options to you, for comment)

i am looking forward to it. i work on deckchair and i have same problem

.

.last question please

@steved said:feel free to IM me

- what is IM?

Hi Jaryn,

- No Fibonacci played no part in this

- Nothing like it at all.

- I understand your approach with you questions that’s fine.

3a Apart from infringing on an existing patent, there are a number of issues with that concept both aesthetic and technical. I am not prepared to go further than that ( as I have mentioned this product is the child of ten years of R&D on making another design that looks impossible but made possible the results of which is a complete new aesthetic. I will let that one out of the bag in about 2 months. If you could actually touch, feel “Laya'

the nuance would be obvious the weight is perfect and on the predicted target The model was tested for stress computer analysis and is “best fit for purpose” For example: no movement when it takes body weight, it flexes immeasurably BUT when it takes the weight it flexes enough so that the weight is transferred to the 'legs' with enough rotational flexion that it conforms to an uneven floor as a maximum BEAM load and not PIONT loads. - It was a close call between laser and routing, but routing won for me. You are right. edge finish won out. CAUTION: The type of wood in the Ply i.e. hardwood’s or softwoods and there respective resin content will play a part in your decision.

As far as the rocking chair I came up with maybe 50 or so variables on the theme as part of design correlations process a few of which were rocking chairs. The only one that looked so right and so perfect is the version you have seen. Because I know so intimately every radius and curve everything else looked like a train Wreck.

I am looking closely at the final treatment of the soft component and am looking at aniline leather (it is more an emotional response I am after to the materials in the context of Laya)

or this new surface, check it out at: http://myface.com.pt/foamcoating.html I would appreciate your input.Errr sorry typo PM not IM (personal message icon under signature)

I would be happy to assist you with you project if you wish. I can tell you have done some work by the intelligence of you questioning. Yes it is a Lo...................ng hard frustrating road but ultimately

such a personally rewarding journey. Just to correct you, product development it is NEVER not a frustrating process NEVER, but you just hope the outcome is commensurate with the pain.It is nice to communicate with those that understand the birth process, LOL

One last thing if the product was 'hit and miss" (beam no beam) the "platform would have to be twice the thickness = Train wreck!Thank for your best wishes for Sydney

Stephen

-

Well done!

Good luck in Sydney!

-

@steved said:

no movement when it takes body weight, it flexes immeasurably BUT when it takes the weight it flexes enough so that the weight is transferred to the 'legs' with enough rotational flexion that it conforms to an uneven floor as a maximum BEAM load and not PIONT loads.

this sounds great

, i did not realisedat first that could work this way.

, i did not realisedat first that could work this way.@steved said:

As far as the rocking chair I came up with maybe 50 or so variables on the theme as part of design correlations process a few of which were rocking chairs. The only one that looked so right and so perfect is the version you have seen. Because I know so intimately every radius and curve everything else looked like a train Wreck.

last sendtence

LOL

LOL@steved said:

Just to correct you, product development it is NEVER not a frustrating process NEVER, but you just hope the outcome is commensurate with the pain.

it's about point of view, but i have to agree with you.

@steved said:

One last thing if the product was 'hit and miss" (beam no beam) the "platform would have to be twice the thickness = Train wreck!

please no.

ok rest in PM. jaryn

-

@unknownuser said:

No possibility to make a sort of rocking chair?

[attachment=0:3lmldqfx]<!-- ia0 -->rocking.jpg<!-- ia0 -->[/attachment:3lmldqfx]

good idea

-

@unknownuser said:

No possibility to make a sort of rocking chair?

[attachment=0:19xqag00]<!-- ia0 -->rocking.jpg<!-- ia0 -->[/attachment:19xqag00]

Sorry mate I thought that was attached to another post. Yes it may be possible to work as a rocking chair. I went for aesthetics (elegence) though, and that configuration was the best. I did do some rocking chairs and about 40 or so other permutations as part of my exploration. Bottom line yes a rocking chair would suit this process

Cheers

Stephen

-

Stephen

I am interested in the engineering process you use in your work. Is this the realm of a structural engineer, or is there engineers who are specifically trained for the field of product development.

I work with structural engineers in building design, and have asked several of them a question to do with the stresses on acoustic guitar cross bracing, and I get the "Deer in the Headlights" response.

Since your analysis was quite thorough, it interests me.

And. I really like your piece. I think it is also really good for people to understand the complexity of fine design when applied to products and industry.

-

That is exactly that I was driving at.... I used to be involved in designing and prototyping furniture. I have a decent amount of experience in laminated ply structures. My suspicion that without lateral support/tension and due to micro climate and extensive use lamination in leg area would fail..

@jarynzlesa said:

Lets start with fact,your product is perfect and everybody loves it

.

.

I like your artefact and than i would like to know something about it.

questions:- did you use golden section rule for design your artefact?

- second question

@steved said:

- Sheet wastage is quite moderate, due to very, very careful 'hand nesting' in CAD(Why they need to be hand nested as opposed to auto-nested is a lo........ng story for another day)

does the sheet look like this? or i am completely wrong?

[attachment=0:nx2bvj14]<!-- ia0 -->sheet waste.jpg<!-- ia0 -->[/attachment:nx2bvj14]

3. question and suggestion

i know design process of new product from its start to end, and i know that is very tough and time consuming process (sometimes it could be frustrating experience) and then please take these sketches as a questions at the begining of the design process than a suggestions of modification.@steved said:

- Yes I designed It from scratch (my discipline is Industrial design) the start point was solving an engineering/ Architectural problem for another design concept. This started off as a test piece to prove the engineering before attempting a more complex piece, but it got out of hand, LOL. Proportions were initially hybrid thinking intuitively compromising, between engineering, ergonomics, and aesthetics. The tweaking after that was VERY comprehensive and very resolved. It is not a deck chair though, it is an interior recliner. I have had one conversation with only one, high end professional who suggested that I should only produce 1000 of consecutively numbered and charge a premium , in the design/art niche. I am still thinking about that.

Stephen

@steved said:

It is a vertical lamination. It is very light indeed (24kg) so lightening it is not an issue.

cheers and thanks3a.i made a quick sketch and quick renders that shows recliner's modification (no lamination process and half weight). did you think that your recliner could look like this at the beginning of your desing process? i think that production is cheaper than laminated version (less material, less work, less machines)

3b. do you think that this could work?

[attachment=2:nx2bvj14]<!-- ia2 -->recliner_uprav.jpg<!-- ia2 -->[/attachment:nx2bvj14]

[attachment=1:nx2bvj14]<!-- ia1 -->recliner_uprav_scena_2.jpg<!-- ia1 -->[/attachment:nx2bvj14]

4. question@steved said:

- CNC routing, water cutting ply will cause warpage the very enemy of this process. This piece was produced in a humidity controlled environment.

what do think if you cut it on laser instead of on CNC router? you get closed surface but with srange color.@steved said:

The piece is about to be shipped to Sydney in about two weeks as it was short listed for final judging, in the 'Edge furniture design competition' at the international furniture fair where it will be exhibited.

good luck in Sydney

.

.@steved said:

And I am interested in some sensitive opinions for options regarding the upholstered component. I would appreciate input, if you would be interested in voicing an opinion (I can present the options to you, for comment)

i am looking forward to it. i work on deckchair and i have same problem

.

.last question please

@steved said:feel free to IM me

- what is IM?

good luck on february in Syndey

.

. -

@dale said:

Stephen

I am interested in the engineering process you use in your work. Is this the realm of a structural engineer, or is there engineers who are specifically trained for the field of product development.

I work with structural engineers in building design, and have asked several of them a question to do with the stresses on acoustic guitar cross bracing, and I get the "Deer in the Headlights" response.

Since your analysis was quite thorough, it interests me.

And. I really like your piece. I think it is also really good for people to understand the complexity of fine design when applied to products and industry.

Hi Dale, I am an Industrial Designer and have only an intuitive skill in engineering, and a friend who is a Mechanical Engineer who did a structural checks via a computer program.

The structure of musical insruments though has almost always baffled me. The material strength of a sound board of a harp is about 1000 times what you would intuitivly expect a 3mm piece of wood could handle before failure AMAZING!! and considering inherent resonent frequencies no less! And done by experience and intuitioin before the days of computers. I think it was called art then

If you have any specific question feel free to get back to me

And thank you

Cheers

Stephen

-

The design is special.

Advertisement