Revit to SketchUp [Rant]

-

Sucks big time.... I am just saying...

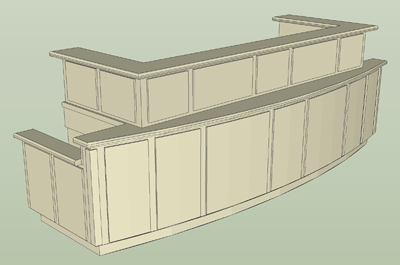

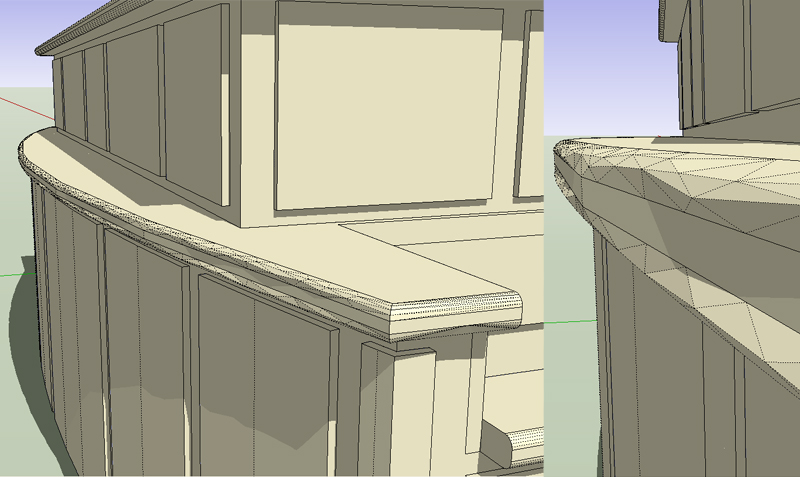

And yes, I understand it is a Revit problem not SU. I built this in Revit then exported as a dwg and brought into SU. Not only the obvious but there are so many other issues wrong with this model it is just sad.

I need this model in Revit so I built it in Revit.

I was just going to "play with it" in SketchUp. It is not an issue, I am just ranting.

-

Time for a relook at 'Autodeath'

-

not just revit, but from what i know, autocad architecture does silly things too... splits up surfaces, triangulates all over the place, etc. etc.

-

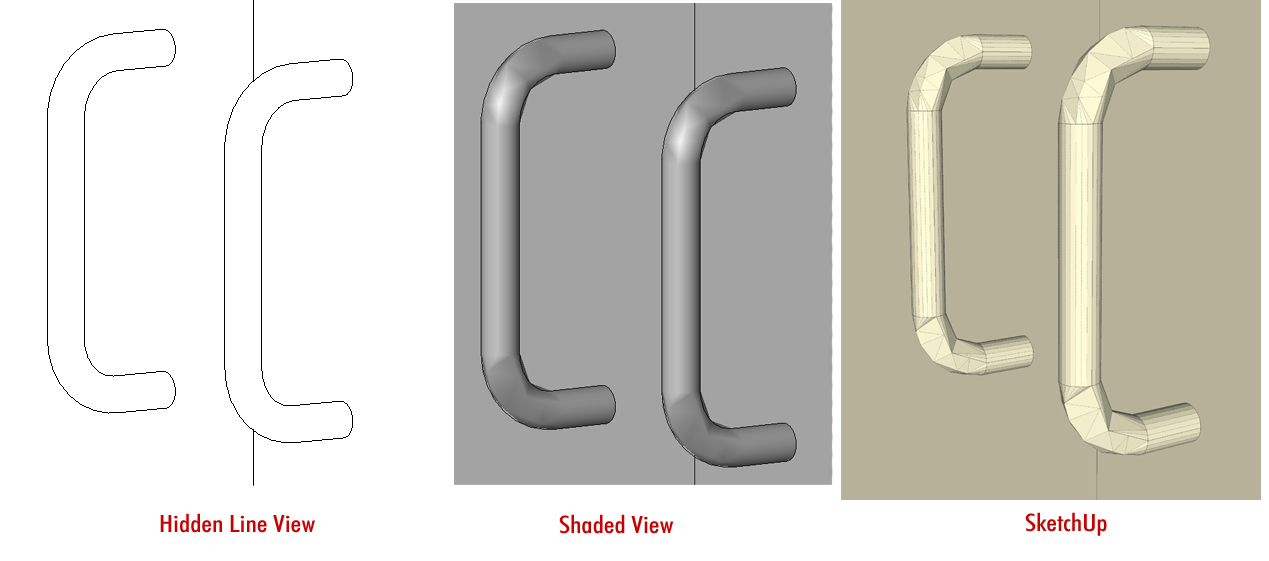

Yea - I've seen that too. You get cylindrical columns from Revit that's been faceted into thousands small triangles. STupid thing.

Though, this does not happen with all the file format you export to.

What did you use? .3ds or .dwg? -

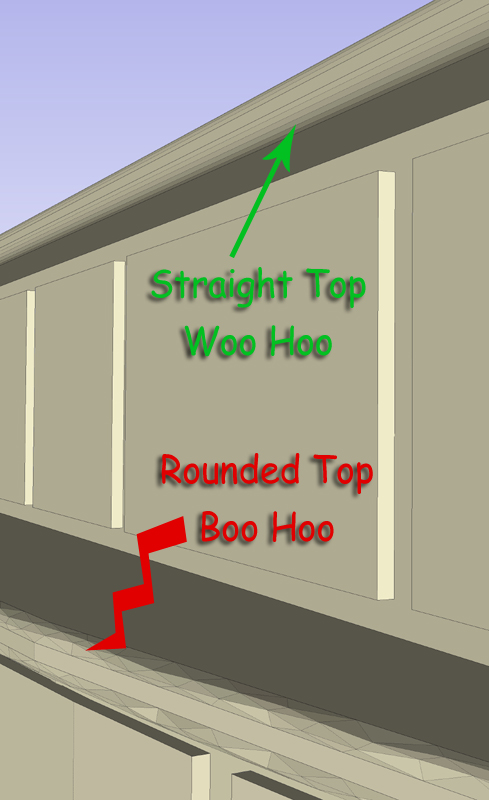

Boo, not a Revit user, but would it be incorrect to say that Revit selected the kind of surface to use in order to optimize the performance of its model? The straight bull nose is optimally constructed with rectangular faces, while the arced bull nose is best suited for a triangular mesh? That being the case, perhaps its SU lack of tools to work with mesh that is the problem.

Again I demonstrate my ignorance with this speculative post:-) Sigh.... I better go and find a hobby.

-

No - it does not optimize. A cylinder is not optimized by thousands of triangulation.

-

But Boo's triangulated mesh is not a straight cylinder (the one at the top of the case), it is the curved bull nose below the stright one.

-

@thomthom said:

Yea - I've seen that too. You get cylindrical columns from Revit that's been faceted into thousands small triangles. STupid thing.

Though, this does not happen with all the file format you export to.

What did you use? .3ds or .dwg?been using dwg... maybe i should try .3ds?

then there is an issue with the windows / doors / etc. needing multiple steps to turn them into 'solids' for them to come into skup so i can see them. i've often rebuilt things from scratch so i get clean surfaces to work with.

-

@bmike said:

then there is an issue with the windows / doors / etc. needing multiple steps to turn them into 'solids' for them to come into skup so i can see them. i've often rebuilt things from scratch so i get clean surfaces to work with.

Ditto.

Another issue is that I often find that models that comes from Revit has small accuracy problems. tiny fraction off axis.

Or dividing a face with he line tool and I get double set with faces on top of each other. -

@thomthom said:

@bmike said:

then there is an issue with the windows / doors / etc. needing multiple steps to turn them into 'solids' for them to come into skup so i can see them. i've often rebuilt things from scratch so i get clean surfaces to work with.

Ditto.

Another issue is that I often find that models that comes from Revit has small accuracy problems. tiny fraction off axis.

Or dividing a face with he line tool and I get double set with faces on top of each other.same here! the off axis is a head scratcher - especially when a component is created out of 'solid' or a block. usually i'm just using this for 'presentation' and to work out kinks that are easier to model / discuss / show in sketchup - but it is a pain.

we are trying to write a script to automate turning 'solids' into true solids. it will run in our 3rd party timber overlay... initial results look promising.

-

@honoluludesktop said:

Boo, not a Revit user, but would it be incorrect to say that Revit selected the kind of surface to use in order to optimize the performance of its model? The straight bull nose is optimally constructed with rectangular faces, while the arced bull nose is best suited for a triangular mesh? That being the case, perhaps its SU lack of tools to work with mesh that is the problem.

I can see what you are saying but see this drawer pull for example. There is no reason for this IMO. The first two are Revit views. The problem is obviously on Revit's side, not SU. Hidden line view looks like it should but once you go to shaded view you can see the problem.

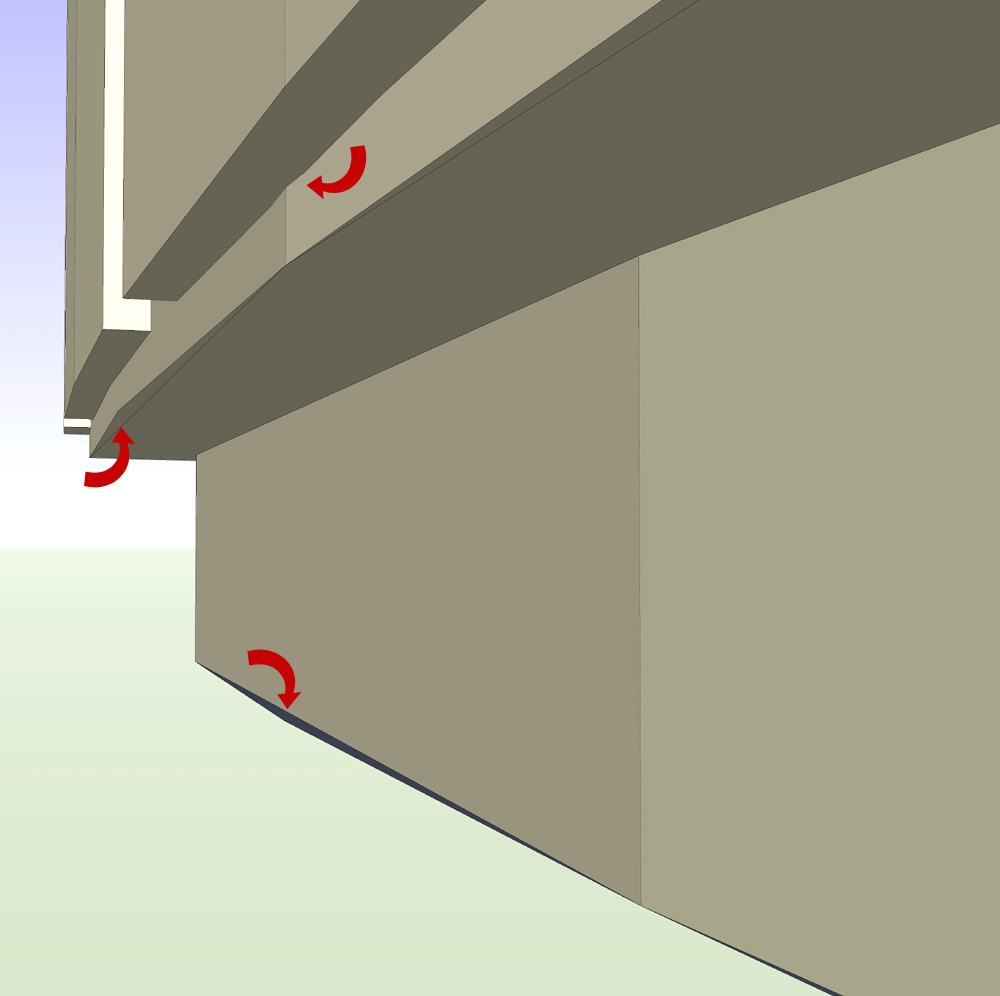

Or these problems. Why the extra triangulated faces at the bottom of the arc?

@thomthom said:

What did you use? .3ds or .dwg?

I used .dwg

Correct me if I am wrong but I don't see an option to export .3ds from Revit. I am using Revit 2011.

The only formats I see available are .dwg, .dxf, .dgn, .SAT and .FBXAnd one last thing. This counter was made in separate sections. Every panel is a separate extrusion yet when brought into SU most everything is exploded. Frustrating.

-

I have tried with .FBX - and then used Autodesk's FBX converter to convert to .3ds.

-

Does it work any better?

-

FBX will preserve materials - while DWG will have none. But DWG preserve components better.

I made a crude script that iterated the model and applied some basic materials to DWG imports from revit - does most of the work. -

Hmmm........ So the problem is apparent in revit. Sort of like SU's default number of edges in a circle. At least SU provides the user the option to change the number of edges. Well hope you fellows can find a acceptable solution.

-

It would be trivial to write a Ruby that welded coplanar triangles back into polygons.

Or is this something different?

Adam

-

That is the problem Adam, they are not coplanar. See image.

I have also attached the main curved part of the counter for review. The geometry is simply a mess.

-

I think I can see what is happening. Revit is trying to coalesce triangles. You can see this from your pic.

I think what is happening is the tolerances for flatness are being confused the scale of the curvature. Imagine a single triangle. Is has 3 edge neighbours which are potential candidate for merging. If the curve is sufficiently small scale then Revit could mistaken choose a neighbour on the curve rather than the triangle that completes a Quad ..again and again.So see if there is a tolerance for flatness/planarity that can be tweaked. You could also try doing a scale up of your model in Revit before export to workaround any hardwired tolerances in the exporter.

Adam

-

Ah, I see where you are coming from now. I will try to remember to have a look this week for a tolerance.

-

Is there a difference between exporting the model from Revit as a polymesh or ACIS solids? I must try myself, but I am just trying to learn Revit and haven't made anything spectacular to play with yet.

Anssi

Advertisement