Dealing with Complexly Curved Facades?

-

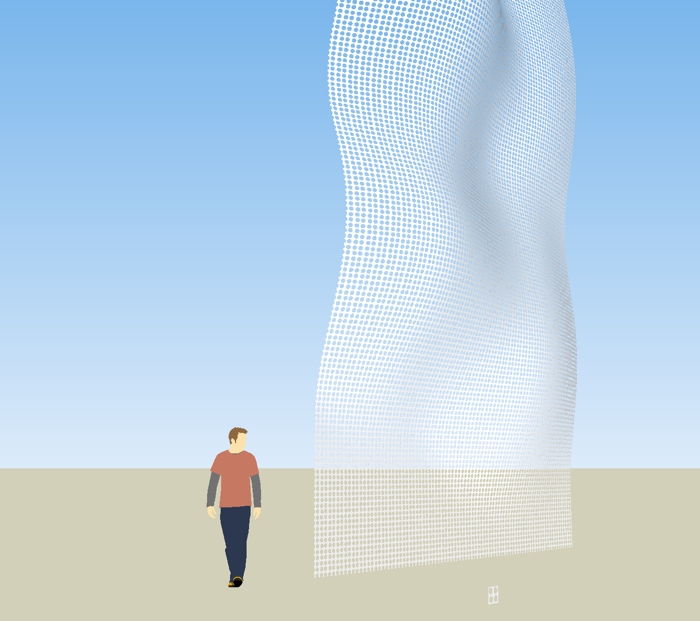

On a more practical note. While out for a kayak I wondered if I could use a texture with transparency to simulate a perforated mesh surface. Works nicely except for shadows.

-

@fbartels said:

On a more practical note. While out for a kayak I wondered if I could use a texture with transparency to simulate a perforated mesh surface. Works nicely except for shadows.

[attachment=0:3iqgkovs]<!-- ia0 -->screen test.jpg<!-- ia0 -->[/attachment:3iqgkovs]

Unfortunately, in SU the texture won't cast the shadows you would actually expect from a perforated surface...the transparent portions of the texture are opaque to sunlight. That's really irritating.

-

Lewis or Chris,

Will renderers correctly cast shadows with a .png texture with transparency?

Fred

-

I don't render in SU. Rhino Render and Blender will cast shadows correctly if you place a transparency map (a copy of the bitmap where white represents no transparency and black represents full transparency) in the Transparency channel. If you don't put a transparency map in the correct place, you get the same problem as you have with SU, in that transparent portions of the bitmap still cast shadows.

SU doesn't have native multichannel rendering, unfortunately.

Yet.

-

When using a so called 'clip map' texture, yes.

Most render apps support 'clipmaps', 'opacity maps' or 'transparency maps'.

All different names for similar functionality.

A clip map basicallly is a black and white image where the black parts usually are the areas that will be 'clipped' i.e being made completely transparent. (A mid tone grey will have semi-transparancy, while full white will keep full opacity etc...) -

In Kerkythea you can choose the alpha mask to work as a clipmap (so you need not edit your image to create a real clip map). AFAIK Tomasz' latest SU2KT sets this parametre automatically (but I'm not sure).

-

As for who uses what software:

Gehry certainly was using Catia. In 1997, as a student, I did a work placement in London. The firm I was working for were designing interiors for the "Experience Music Project" building in Seattle. All the data from Gehrys was from a Catia system.

http://en.wikipedia.org/wiki/Experience_Music_Project.I went to a Zaha Hadid exhibition several years ago at the Building Centre in London. Rhino was referenced as a production tool.

British Aerospace (aeroplane builders) is just up the road from me here, they use Catia.

-

Both Gehry and Zaha taught in my graduate program at Yale, which I finished in 2005. We received a full indoctrination.

Gehry tends tends to hire his grad studios, interestingly enough.

Anyway, the first major project they used the aerospace-derived software CATIA on was that big ol' fish thing at the Vila Olimpica in Barcelona in 1992, followed by the Rasin Building in Prague in 1996. Most famously, CATIA was use with the Guggenheim Bilbao in 1997. But Stata Center in Cambridge was the last Gehry Partners project with CATIA itself. Since then, a separate company founded by Gehry, Gehry Technologies, has put together an architectural package called Digital Project ("DP"--it's the CATIA engine with a GUI designed for architecture, a kind of super-BIM), which of course gets pride-of-place in his work process. Zaha's firm and SOM have also begun using DP.

http://www.gehrytechnologies.com/index.php?option=com_content&task=blogcategory&id=8&Itemid=65

We've been looking into getting educational licenses where I teach...it's pricey, at about $16k for a base seat, but that is considerably less expensive than a full seat of CATIA.

My former classmates at FOGA describe DP in these terms..."you dimension first, then it tells you based on your material qualities what shapes you can achieve." I'm doing OK as an architect, but I can't justify that cost on my own so that I can verify that.

We're getting really far afield here from SketchUp, though...

On behalf of my school, I've also been looking at some licensing for Bentley's equally "swoopy" rival to DP, called Generative Components ("GC").

Do you know what the Bentley people said, in the first five minutes of our conversation? "...and it can import your SketchUp models natively, and even pull entourage from the Google Warehouse."

-

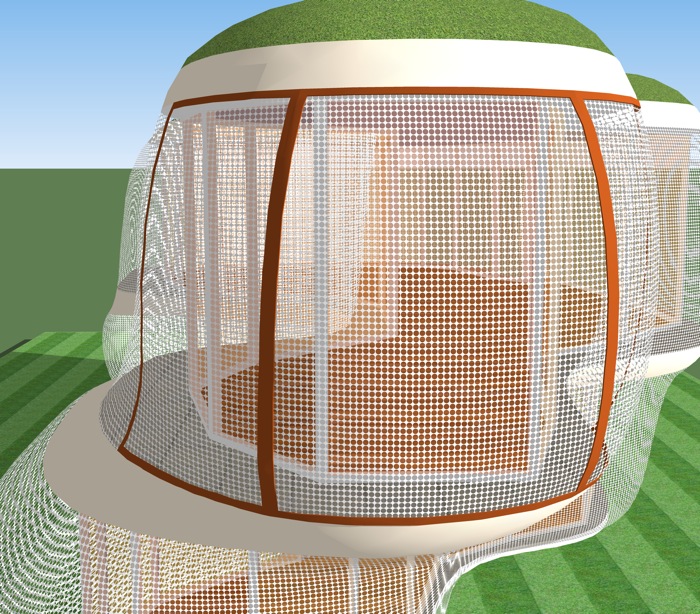

A quick and dirty (ok, not so quick and actually pretty clean) attempt at using a curved perforated "screen" for a building. Meant to spend about an hour on it but it took two. Urghh, and it is a beautiful day outside.

I didn't attempt to align the texture to the different screen segments (actually I started to but it was so tedious I gave up) so there are lots of moire like effects, however I think the general idea comes through. Not sure if this is worth pursuing even though it is kind of interesting.

-

Most "perf metal" sheets have very limited spanning capability and no stiffness to speak of, Fred. That means you need a framework behind them, with secondary elements to tie the framing into the main structure (and we're not even thinking about wind loads yet).

Also, perf metal is essentially a factory-made sheetgood: it won't take bends along multiple axes and doesn't deform neatly. For a given sheet, you can put onenice bend in it, in onedirection, in other words, without making cuts in the sheet.

A piece of stiff paper is a good cognate for the behavior of metal sheetgoods, incidentally. Imagine how you might make your shape out of stiff sheets of paper (without crumpling them and with a minimum of cuts), and that will give you some idea of how you might approach this project should you continue to pursue it.

-

@lewiswadsworth said:

I don't render in SU. Rhino Render and Blender will cast shadows correctly if you place a transparency map (a copy of the bitmap where white represents no transparency and black represents full transparency) in the Transparency channel. If you don't put a transparency map in the correct place, you get the same problem as you have with SU, in that transparent portions of the bitmap still cast shadows.

SU doesn't have native multichannel rendering, unfortunately.

Yet.

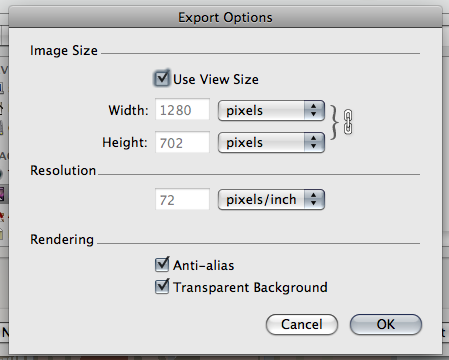

Just a side note: One little surprise when switching to osx, was the fact that sketchup on mac does export tranparency, just remember to export as png, and check the options.

All the other channels (depth and material), can be exported with some ingenuity, though, it´s not a 1 click process

-

Repetition of a planar shape:(project of H&DM)

repetition of a planar shape: triangle. (project of Toyo Ito)

repetition of a 'foldable': (project of H&DM)

-

Indeed, the metal mesh would fall down like a sac as it is now.

Either you make the structure 'self supportive' (Herzog &DeMeuron did a facade like that) by making the mesh itself 3D, but that will never be enough to support a structure like yours as there are too much horizontal forces going on purely by its own weight....OR, a secondary support structure is needed, which in the most opportune case supports a repetition of a pure planar mesh shape or a 'foldable' one (around just one axis) making it more rigid than a planar one.I suggest browsing the internet for works of Herzog & De Meuron (older projects from the nineties) as they have done good experiments on steel meshes and facade skin.

3D- mesh: (project of H&DM)

-

Lewis and Chris,

I'm just playing with ideas here guys. Nothing that is actually going to be built... but you knew that.

The perforated screen is not meant to be in any way structural. (The real support structure could be traditional post/slab stuff.) Think of the perforated facade more as a heavy duty insect screen that can maintain its structural shape (see image). It just needs to support itself, nothing else. There has to be some material -or some way to shape material- that would work for something of this nature. If not, the material scientists need to get to work.

This thing is starting to remind me of an aviary. Maybe it's time to move on.

Fred

-

Don't move on yet! I have been following in the background

I am working on a facade for my Final Major for my degree and this is fatastically interesting!

I am working on a facade for my Final Major for my degree and this is fatastically interesting!

How do you align textures on these surfaces?

I downloaded your model in this thread and the material was aligned perfectly, then I used it on my curved faces and it was all over the place!

Also in the above pic it looks well aligned

-

Hi Geomp,

I agree about this thread being interesting. Kwist and Lewis have been holding a little graduate seminar for all of us.

I'd love to keep the tutorial on complexly curved facades going. Kwist presented some options in terms of small repeatable units. I'm curious what solutions Lewis is exploring? I've got some ideas related to the work I've been doing with complexly curving roofs, ideas which I'll share in the next couple of days. Can you share what you are working on?

Regarding the textures. The key is to align the texture image to the face you want to project onto, then to sample the image by selecting the paint tool and holding down the Command key (on a Mac). Once the texture is sampled you can then use that texture to "paint" your curved surface (both sides). I've attached the png file I used. In this case only one transparent circle is needed because the texture is just that one circle tiled across the surface.

If this isn't clear please let me know.

Regards,

Fred

-

If you like developable surfaces please see the book written by John Sharp about my D-Form geometry. Search Amazon for:

D-Forms: Surprising New 3-D Forms From Flat Curved Shapes

Enjoy.

Regards

Tony Wills

Advertisement