Cordless Drill

-

a lot of people actually hold drills in the palm of their hands and use the pinky and ring fingers on the trigger.. (which puts your arm/shoulder/body directly behind the motor and inline with the bit.. ie- way more power and stabilitly)

i watched the C12 advertisement:

http://video.google.com/videoplay?docid=-5430410674798623774&hl=en#...and it looks like he's constantly putting his other hand on top of the drill to get the extra power But, that's the same place where the gear shift is so i'm guessing the switch gets changed accidentally.

i sort of wish one of these tool companies would do some scientific research on how we actually hold drills and/or how best to design a drill for optimum stability and power.. this gun handle type design has been around forever and surely they didn't get it right on the first try ?

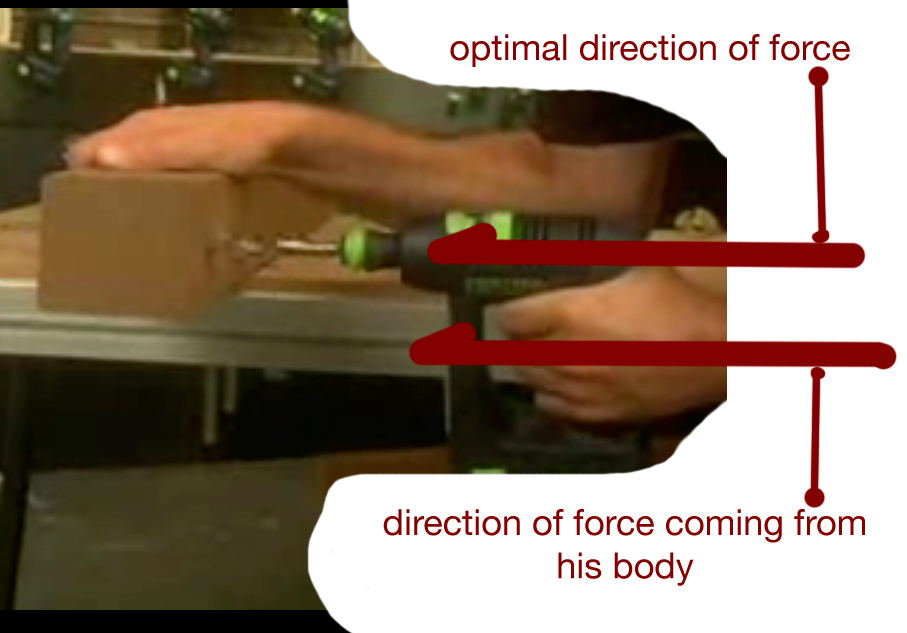

screenshot from the festool video:

-

I use both DeWalt and Milwaukee cordless drills at work nearly every day and have never found the need to hold the drill as you describe. That's just me, though. Doesn't seem like a point worth arguing about since most drills are designed to be triggered with the index or second finger.

-

oh wait, i'm not coming from an argument stance.. just nerding out on drills

i assume you're doing mainly light duty work if you're comfortable holding the drills like that..

my crew doesn't do too much heavy duty drilling but we do use a lot of 3" screws (as in 10000 of them for a two week job) as well as boring up to 1/2" holes in 1/4" steel.

if we held the drills as they're designed to be held, our wrists would break off.. (as it's the wrist that has to make the weird angular change of force from your shoulder to the actual bit.. as shown in the picture above)

anyway, i (and much of the construction industry) am now using an impact driver for the long screws (i'm pretty sure i linked to one last year in this thread).. those things do so much of the work for you that you can hold it pistol style with only one hand and drive 3" screws..

[edit -- well, two years ago.. http://forums.sketchucation.com/viewtopic.php?p=53520#p53520 ]for boring holes, we use a certain dewalt corded drill that fits comfortably in the palm of your hand.. even has a little groove for your thumb to rest.. i'm pretty sure the design was accidental but it works out great.

-

Hi Boo

Sorry I missed the return of this post, I was offline for a few days. You asked about the chuck. The attached pictures show you the set I have got when I purchased my C12. This was not the standard set but was on offer at the time. The right angles chuck and the offset chuck have been absolutely brilliant for fitting kitchens. You can get a screw in anywhere with this kit - right into the corner of a unit or you can screw cornice down onto the tops of units very close to the ceiling. The standard kit comes with the keyless chuck and the centrotec chuck, the latter will not accept standard hex bits - which can be a bit annoying but I have the centrotec bit set as well so it doesnt affect me too much. I hope this helps and enjoy the new toy - it is a great piece of kit.

-

I'm late to the party as well... The centrotec holder will NOT hold anything that doesn't come from Festool. Standard bits like you'd buy at one of the big box stores won't fit unless you take a belt sander to 'em, and even then the groove is in the wrong place for them to lock into the chuck. I honestly don't remember if a bit holder comes with the kit, but the BHS 65 holds standard sized short driver bits. Problem solved

If you don't get one with your new drill, Festool's part # is 492 539. I think you're gonna like it Boo!

If you don't get one with your new drill, Festool's part # is 492 539. I think you're gonna like it Boo! -

Thanks.

It came in on Wednesday and I was not able to open the box until yesterday. I got the whole kit like Dermot shows.

Batteries charged and ready for action... I think I have a fence that needs fixing. -

Cool! How could you hold off on opening that box?

-

Trust me it was real hard. I had a bunch of work to do and for two nights did not get to bed until after midnight.

-

You shouldn't be on the computer today, then. You should be out making like a woodpecker on your fence.

-

But it was break time with a glass of ice water in my other hand. It topped out at 98 before the skies let loose and our house, then later on the road my truck, almost got hit by lightning.

-

Wow!. Well then I don't blame you. Glad you didn't get hit. Hopefully there was no damage.

-

Nope, no damage other than a paranoid 10 year old now

When I was a young'n living in Plano, TX our house did get hit by lightning. The chimney exploded sending shards of brick up to 3 blocks away. Our old electric organ got fried, some funky metallic wallpaper we had in the hall bathroom had new streaks all over it and the doorbell button disappeared. We were at church when it happened. -

Good golly! And the doorbell button disappeared?

-

So an update. I love this drill. I was putting together some furniture tonight and needed the right angle attachment, worked brilliantly.

Also, during halftime of the seriously depressing Tennessee LSU game I was watching the end of a "This Old House" and beginning of an "Ask This Old House" episodes and in both Tom Silva was using his Festool C12 and T15 drills. And odd enough the end of the TOH episode he was installing a new Newel Post and the beginning of the ATOH he was fixing an old one.

-

I knew you'd like it.

-

They have a new one out too!! The CXS - great looking lightweight cordless:

Have a wee look. I have the card out already!!

-

Didnt read the entire thread but if you have some minor electronics experience you can purchase individual cells and rebuild your battery pack. Most often this is FAR cheaper than purchasing a new pack or drill.

If you have moderate to good experience in it, you can find cells with a much higher capacity than the originals and extend the battery life by a large amount.

This is something I have done with laptop batteries in the past. What was a 150 dollar battery pack cost a friend of mine 45 dollars and about an hour of my time.

Advertisement