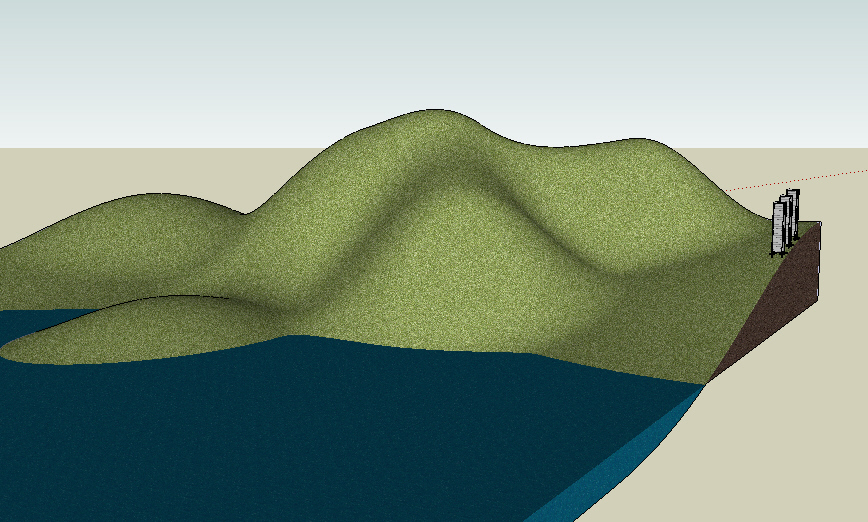

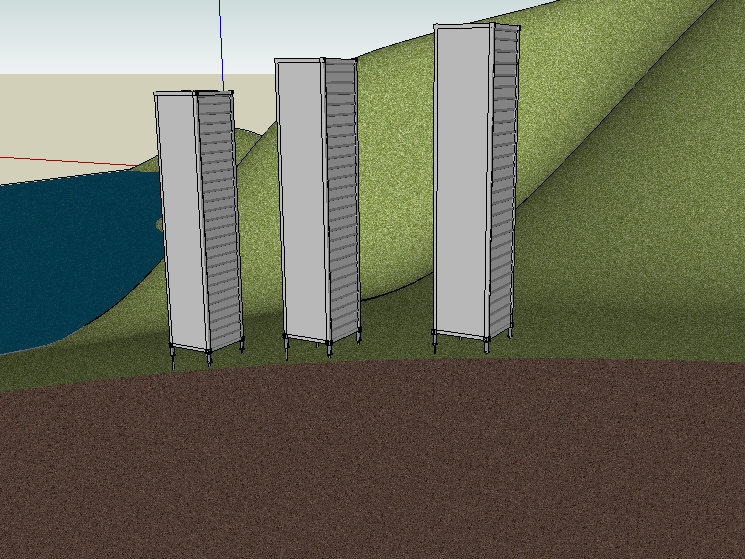

The prefab apartment block.

-

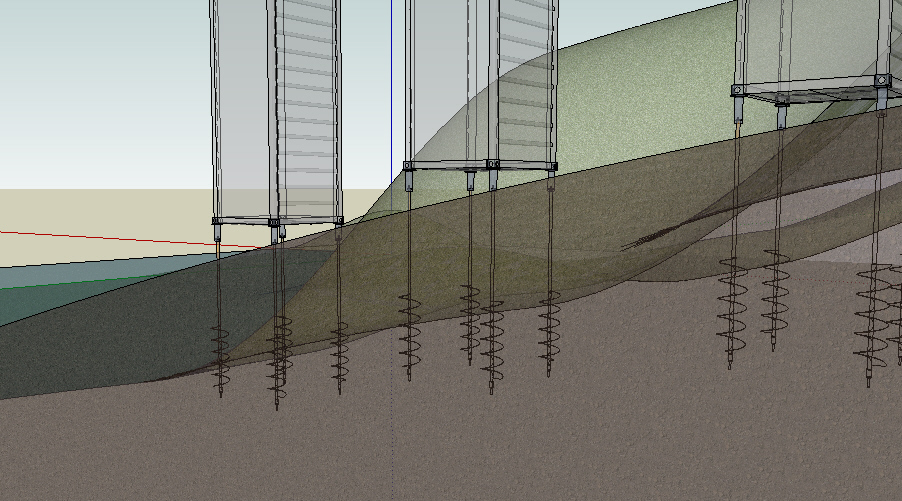

I've seen those screw in supports Ross, a local building used that technique. A hyraulic driven crane attachment holds the screw and basically drills it into the ground. They were 3.6m long and went down to the rockbed as the building was on soft riverplain, the slab was then tied into them.

-

fantastic.

we have several modular systems over here. most go up very fast and are completed in the factory.

people here are very wary of anything new. you see lots of individual mavericks that do this, but as a whole the public has had many options for affordable energy efficient housing. for some reason they just won't switch from platform framing... I guess the lumber is cheap but more over I think it's the common scared/greedy builder who talks them out of it. I see it time and time again with curved walls... builders afraid to do them and preaching that they'll be soo expensive. when I know they are not very much more expensive. especially when compared to the value in appraisal.

anyway... this system you've found looks wonderful if not for the foundation connectors alone. that's a great method.... you could do a lot of different things with those, and they're removable and reusable.

so when will the sketchup components be done John?

-

here's a pic of how it works. You can see the pylons lying on the ground - they have a welded screw thread at the base that scews the unit into the ground driven in by the hydraulic driven screw attachment on the crane.

-

Here's a pdf brochure about that development and its 'BUMA' system: http://www.osborne.co.uk/uploads/BUMA%20Brochure_AW22.pdf

-

I have seen a similar idea in Japan where they put up a house in a weekend.

Similar idea of prefab, prewired/plumbed construction. You went to the retailer and entered your preferences into a computer that built the modular layout on screen. As you constructed it the program read out the cost and the monthly payments in the top right hand corner. Change the stove model for example or add a bedroom and the price changed accordingly.. When you had the layout and features you wanted you hit 'save', the factory then built it amd delivered it to the prepared site.

-

thanks for sharing this, john. i am going to forward it to my design students.

cheers.

-

Thanks for the heads-up John. I'm currently putting some

ideas together for a system build and this was very

helpful.I now wondering if we should have some kind of a sub-

forum for Construction Technology as many of us here

are involved in this field!What do you guys think? I would hate to see too many

forums but these could be reorganised at a later stage

when things settle down.Mike

-

another method is to make the thread a stickey so it stays on the front page and doesn't get shuffled down. The number of stickeys will build up and then you can decide what to do with them.

-

Thanks for the info John, this is very useful.

Im currently undertaking some feasibility studies for 20+ small plots of land in my City. Part of my job is to advise what should go on each site.

This looks like it could be a very good option to consider and look into a little more.I really like the look of the finished units.

-

the foundation piling inspired me to connect it to shipping containers... mmmm you could put them anywhere and then move them.

Advertisement