Roof Membrane Advice

-

Sketchy,

I've been wondering if a foam/plastic mesh combination might work in a similar fashion to ferro-cement. I was looking at nonwoven geofabrics on the web today (see image about halfway down this page) and it seems possible that if you combine something like this with high or medium density foam you could get a really strong lightweight structure.

-

Sailcloth might also be an option. A cloth membrane could be quite tailored. One approach could be to fabricate the 'honeycomb' with tie-down loops so when it's time for adding the sailcloth you overlay the honeycomb structure with loose straw and then cover with the sailcloth and tie it down. The fitted sailcloth having been produced with reefing lines on the underside that can tie down through the insulating straw to those tie-down loops. The result would perhaps look rather... upholstered!

When Sketchy writes the reminder that the denser the foam, the lower the r-value it made me wonder if your basic honeycomb approach of using high-density foam for strength is perhaps overkill. Sure you can make it strong -- really-really strong, but does it need to be? I imagine low density foam is less expensive and yet might still be plenty strong enough to hold it all together.

Regards, Ross

-

Regarding geotextiles...

Unless you have a local supplier where you can go and see the various kinds it might be hard to determine which product is most suitable. As an alternative I'd suggest going to your local Home Depot or other building supply store and check out 'Cedar Breather'. It is a non-woven plastic material about 1/4" thick intended to be used under wood shingles to provide a continuous air space under the shingles. The material is 'loose' enough in its weave (although unwoven) that I suspect it would be a very good reinforcement for either a foam or cementitious covering.Regards, Ross

-

Your idea about using those tube sections, and filling them with foam is a good one, but you have to plan for building it in the real world too. Have you thought about how you'll support it from underneath while everything sets up?

-

Ross,

Point taken about the 8 lbs high-density foam perhaps being overkill. I hope this is the case, as I really want to use spray foam which tops out at 3 lbs. More testing.

Thanks for the lead on the "Cedar Breather". Once more into the home center!

Fred

-

@joe wood said:

Your idea about using those tube sections, and filling them with foam is a good one, but you have to plan for building it in the real world too. Have you thought about how you'll support it from underneath while everything sets up?

Joe, Yeah I've thought about it. Obsessed about it would probably be more accurate.

See the following:

and http://openarchitecturenetwork.org/node/472

Basically the honeycomb structure is the middle layer, above (and supported by) the TIN structure, and below the various surface membranes (and soil/plants in the case of a green roof).

Sorry you asked?

Fred

BTW, I'm loving your curved roof model. I'm a huge fan of traditional Japanese architecture.

-

Ah, no, but don't you see? That house 2 won't work because all the plates undulate all over. You could never build that. You need to start your roof model off of a more realistic plate.

Maybe look at eyebrow roof dormers to get some plate layout ideas? That's a practical way get your roof undulations.

That's a real neat model though!

-

On, that isn't traditional at all! It's a western style roof. That's what's so neat about SUp, you could never design and build something like that without a 3D modeler.

-

Wow quite a flurry of posts since I checked in last. To answer your earlier question a qualified "yes". Many material combinations will work like a ferro-cement skin. The one you suggested may work. The problem might be that the tensile strength of the fabric would not be known and it may seem strong but may not stand up to windshear etc.

I think that if you are serious about making this a habitable structure then at some point you would need to talk with an engineer and watch his eyes bulge when you show him what you want to do

. The reason I like the crackmaster fiberglass fabric (3' x 90' roll I think) is it is made for this type of application and has known tensile strength you can depend on.

. The reason I like the crackmaster fiberglass fabric (3' x 90' roll I think) is it is made for this type of application and has known tensile strength you can depend on. -

Well Fred ,

We like to do the things with EPDM roofing that are (almost) impossible.

Al our Epdm-roofs are produced from cad files ,every 3D-form is first drawn in Sketchup

Surveyes on existing roofs are done by trilateration of the differend faces of the roof.

a nice free piece of software to help with this is ''Sketchflat".

Dome-like structures can only be approximeted EPDM Dome.skp

Please post a sample file of a roofing face and i will let you now if it can be prefabricated.Greetings Bep van Malde.

-

Beb,

Thanks for sharing more about the EPDM fab process. Since my goal is to produce curved roofs like the one in this image, it may be more appropriate to use a more modular layered system.

Fred

-

@joe wood said:

Ah, no, but don't you see? That house 2 won't work because all the plates undulate all over. You could never build that. You need to start your roof model off of a more realistic plate.

Joe,

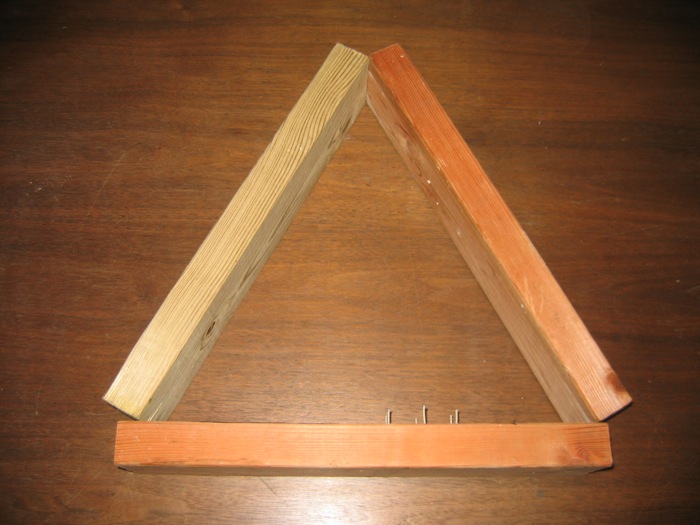

These images should make it clear why a TIN framing structure should work well.

The first image is just 3 2x4 pieces in a triangle. It represents one triangle frame segment of the many that would make up the whole frame.

The next two images show how a honeycomb of PVC pipes drapes over a frame segment. I'm fairly confident that a honeycomb mat of PVC pipes would form a nicely curvaceous surface. Once the surface was tweaked to get the curves just right then the high-density foam could be injected, locking the shape in place. That's the theory anyway. As I do more experiments with small structures I'll share the results here.

Fred

-

Well, yeah, the whole curved roof system will probably just work just fine, but the outer edges of the whole assembly needs to bear on a plate line doesn't it? Also, maybe that TIN system needs the walls to be a little buttressed maybe, resisting outward thrust? I'm saying the plate line/top of wall needs to be more realistic. Your existing plate line is shaped like a roller coaster now, and how's someone going to build that out in the field.

Seems like you should concentrate on that major issue before you go too much further with the roof system. You might just need to start out with a level plate line. That TIN system is how geodesic domes are built then?

-

I agree with you Joe that it would be much easier with a level top plate but it's certainly not impossible. An undulating top plate can be built as a laminate. Imagine building a wall with only the bottom plate (run the studs wild). Draw the curves you want on a strips of 3/4 plywood. Attach these to either side of the studs and then cut the studs flush to the curves. Now work up a top plate a layer or two at a time using the bottom edge of the plywood to clamp to.

Not the easiest or cheapest way to go, but I don't think that's the primary concern in this project.

-

I don't know Sketchy, I do alot of laminating, and curves, and laminating curves that curve in two directions is very difficult, especially with extreme curves as in Fred's model.

Not impossible, but something he should address before he gets much farther into this design.

-

Good point Joe, I really didn't take as close a look at the model as you did. Compound curves would be a nightmare. It is something to address for sure. It would be worth it to look at the plate line and mellow out the curves to make it more reasonable to build. Perhaps reighn it in to undulating curves instead of wild curves.

Anything is possible with unlimited time and money but who has that?

Advertisement