A Moxon-Style Vise

-

Unfortunately I'm not at liberty to share the model.

-

@dave r said:

Unfortunately I'm not at liberty to share the model.

No worries, thought that might be the case.

-

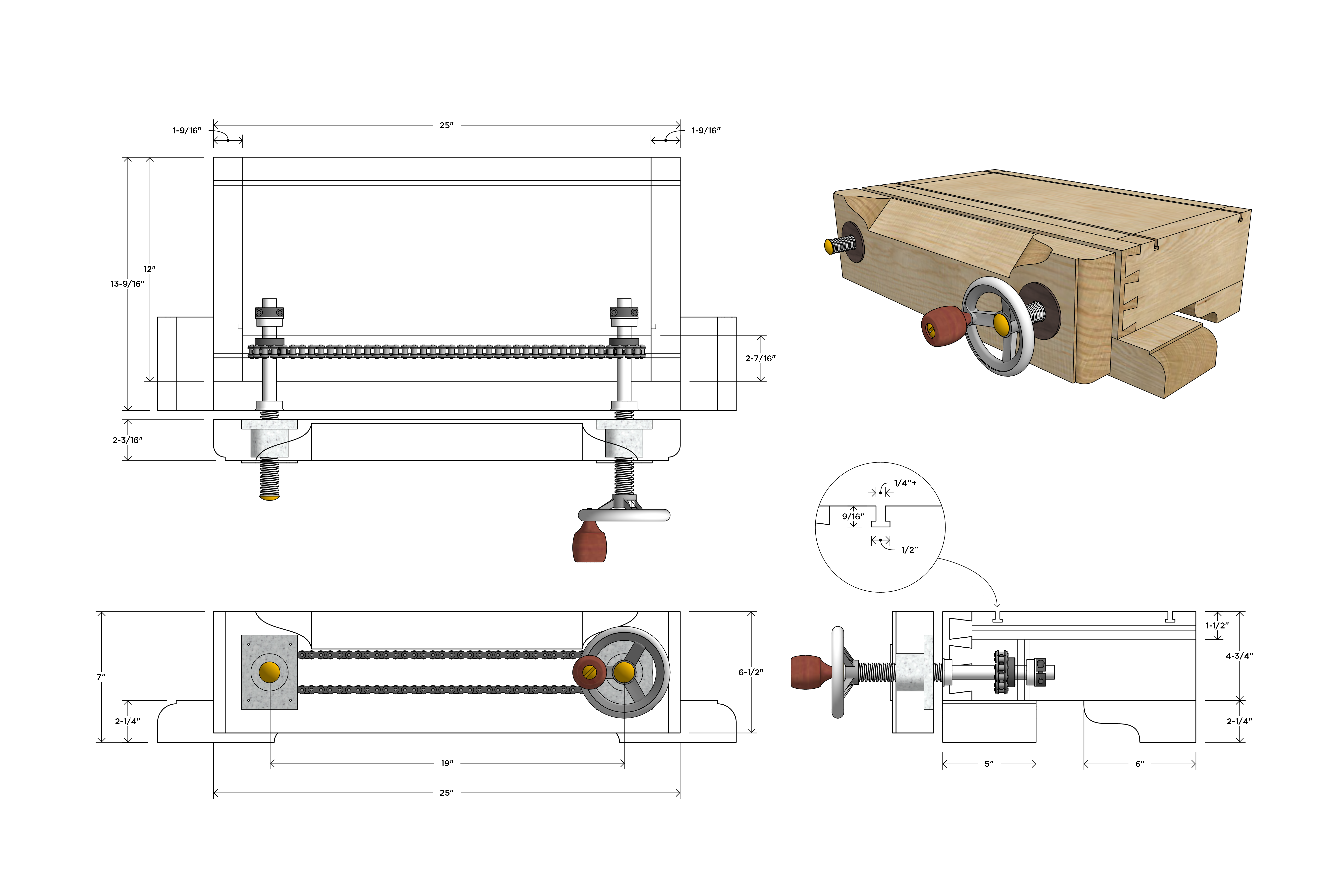

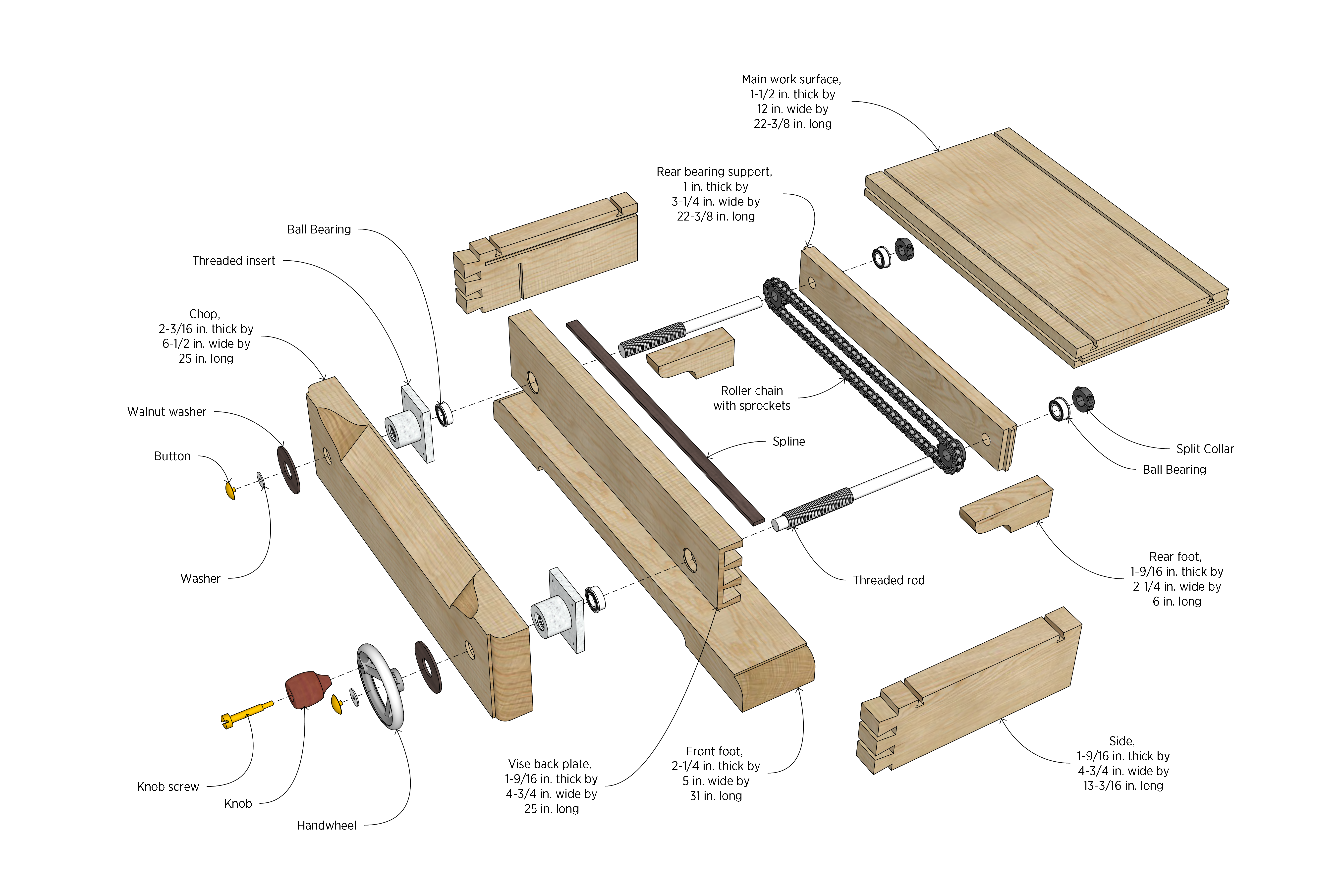

Here's a work in progress shot of another Moxon-inspired vise. This one is considerably more expensive to build, though. The screws are Acme left-hand threaded rods that have been turned down over a good part of their length. The left hand threading allows the chop to be moved in when turning the handwheel clockwise. The main body of the vise has sides dovetailed into the front piece. Just waiting on some dimensions for those bits.

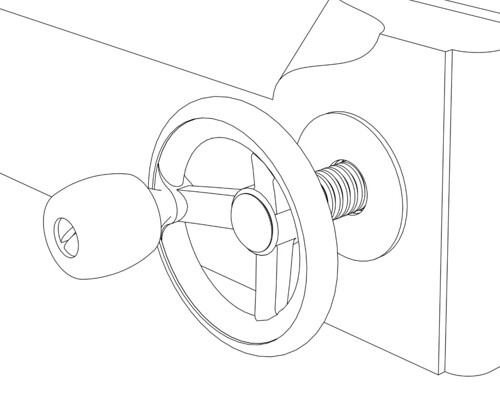

Here's a view from earlier when I was working out the order of the round bits that go on the shafts.

-

-

Fab drawing, love the combination of solid line and x-ray. (Now to figure out how you did it

-

Great drawing thanks for sharing! That is an ambitious project (drawing and fabrication) for sure. What is the inspiration for this vice or is it a copy?

-

Thank you, gentlemen.

baz, I'll be interested to see what youcome up with for that.

jtri, this latest vise is from a design by a woodworker on one of the woodworking fora that I am a member of. Interesting point: He used solid counter top material to make threaded inserts for the chop so it moves in and out with the turn of the hand wheel.

-

I have used "corian" for many things other than counter tops but not as a nut! Your texture should have told me what the material was. Is there a metal insert in the nut or are the threads to be cut into the "corian"? I need a small metal lathe to cut threads and turn some parts. Now to convince the wife...........

-

The guy who designed and built this vise said he threaded the Corain. He also said it was "not an easy task, but time and patience win out." He made a tap out of a piece of the threaded rod. He tapered the end and cut groves down the length.

A metal lathe would certainly be a nice addition to your shop.

-

I think this is the final of my part in this latest Moxon vise deal.

-

Very nice. Super-clean presentation.

-

Thanks Doug.

-

Fantastic vise!! So many useful and cool details. Oh, really nice presentation too.

Now I just changed my bike chain and cassette and still have the old chain and gears, Going to save them. -

Thank you. Good to have something to do with that chain.

-

FredoGhost perhaps?

@baz said:

Fab drawing, love the combination of solid line and x-ray. (Now to figure out how you did it

-

-

-

Remember this!

thousand of videos of the constuction of this incredible machine!

Advertisement