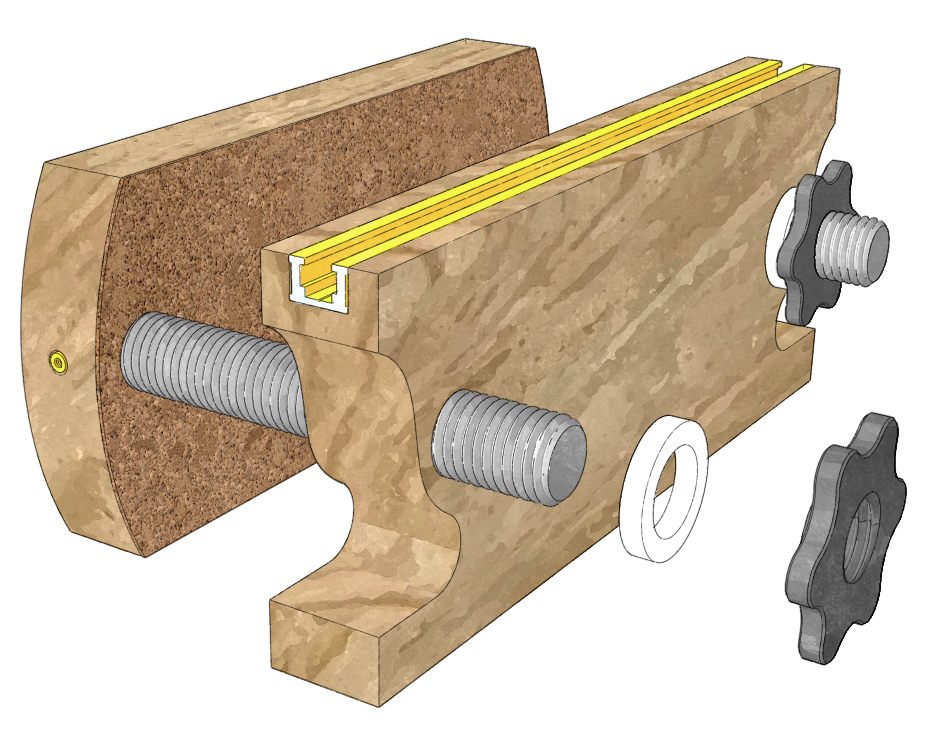

A Moxon-Style Vise

-

This is a model I did for plans for this vise designed by a woodworker in North Carolina. Fairly simple build and cheap. Other than the wood for the chops, there's less than $20 in parts.

It is clamped to the workbench so it can be put away when not needed. -

Great job !

-

Hi Dave. I have been thinking of making one of these.

The function of the track on the front chop is not obvious to me. -

@baz said:

The function of the track on the front chop is not obvious to me.

It's a secret.

Actually, it is used for a couple of hold down clamps. The fellow who designed it uses one to hold a saddle square (he made a wooden one for it today) and another hold down holds the tail board in place while making out the pins. He's been making and using this sort of vise for many years and he says the hold down clamps are really useful.

-

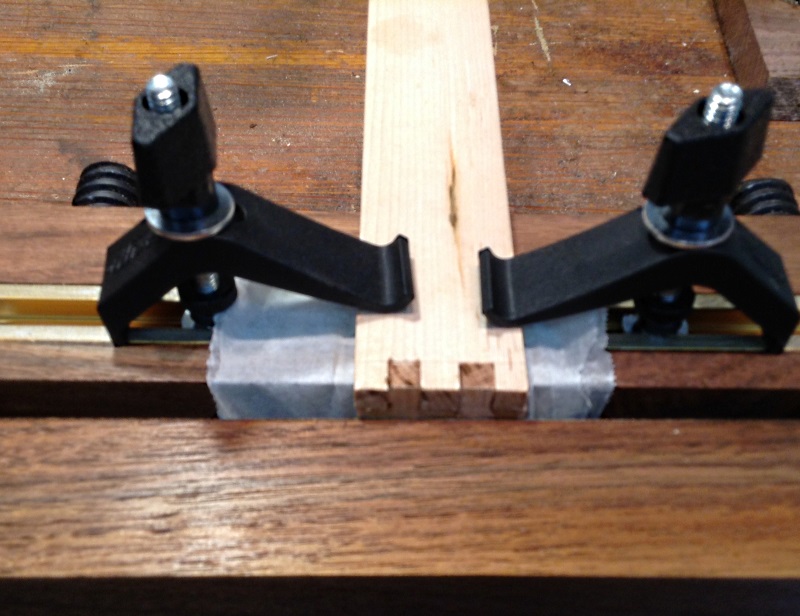

Ah, I see. This style I presume?

-

Yes. Exactly.

-

/quote] Actually, it is used for a couple of hold down clamps. The fellow who designed it uses one to hold a saddle square (he made a wooden one for it today) a.[/quote] Whoops, broke the code:)

Did he make a saddle square for his Moxin. Or a wooden hold down?

Might have to ask him for a pic?

No hurry. -

He made a wooden saddle square. Here is a picture showing the one he made just glued up and clamped in his vise. Previously he used a Veritas saddle square.

-

Adding a square can really speeds things up when setting up to transferring marks. That is an idea I had thought about incorporating into the vice, but I had not done it yet. The hold downs are even a better idea! Thanks to both of you for sharing the tips.

-

I like the idea of keeping the square as a separate thing. You can place it where you want it in the vise and with my luck, a permanently attached thing would just be in the way. Wish I could take credit for the idea but I'm only the messenger.

-

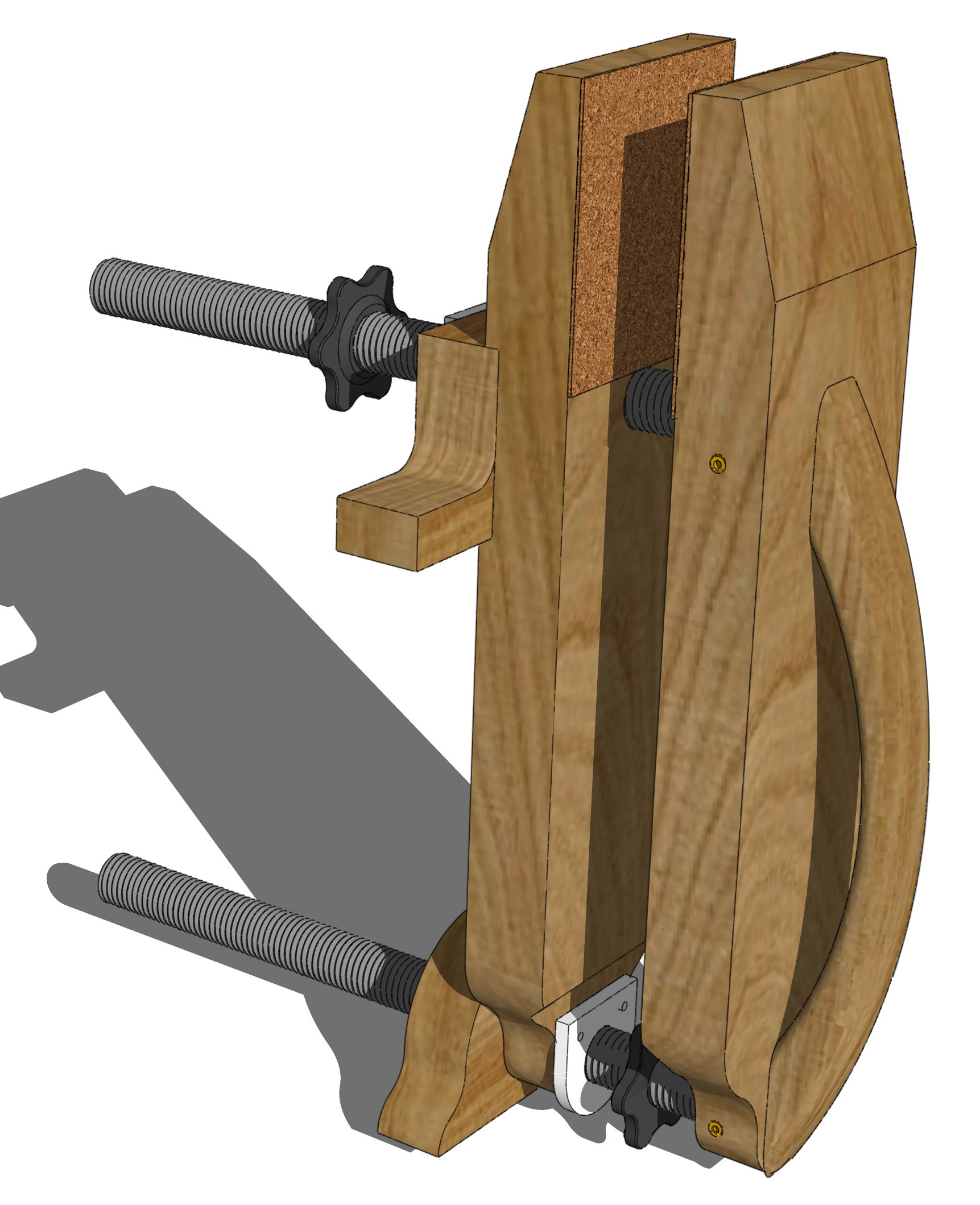

Here''s another vise designed and built by the fellow who did the Moxon-style vise. This one can be clamped to a bench or counter or table when needed.

Modeled for plans like the Moxon.Interesting thing. Both of these use dumbbell handles for the screws. You can buy a screw with two knobs for less than $7 US.

-

Dave you did a great job lining up the edge and face textures

-

Thanks Joe. It's not so hard with a proper texture to work with.

-

@joe wood said:

Dave you did a great job lining up the edge and face textures

So he did, well spotted Joe. The short grain on the handle is a bit of a worry tho'

-

@baz said:

The short grain on the handle is a bit of a worry tho'

It's tough and stringy elm.

I only made it the way the the old head who built it did. It's made out of scrap wood he had around. He probably has more.

-

That would be a handy vice, thanks for sharing. Used some elm on a project and never again. That stuff moves way too much!

-

I wouldn't use elm either. I just made that up. I think he used pine or something else that is easier to work.

I don't think elm is good for much. My father told me that before I came along, he and my mother lived on the second floor in an old Victorian style house that had been divided up into apartments. He was given some elm to burn in the fireplace. He said he'd burn the same log for three or four nights. When they were ready to go to sleep he would put on asbestos gloves, grab the log and throw it out the window into the snow. In the morning he would go collect it and bring it in so it would dry out. He said it didn't give off much heat, either.

-

You are both right about Elm, nasty and unpredictable to work with and tough as old boots. It rewards you in the end but its a battle. I used it in Pommieland many years ago.

Of course, now, Dutch Elm disease ruining city landscapes.

And funnily enuf: on the news tonite, A lady walking down one of our leafy Melbourne boulevards today, got fatally crushed by a hundred year old healthy Elm. (Theres more to this).Is this a Hijack? Never sure.

Anyway, I love the portable Leg Vise. I want one. Suits my lifestle. But goes on the project list about 90 down.And the story, Dave, sounds intriguing. The 'Old head'. More please.

-

I don't know much more about the "old head". He's a member of one of the woodworking forums I participate on and he seems to have a vice for shop made vises. The screw is typically the most expensive part but he came up with the idea of using these cheap dumbbell handles which work quite well. He also buys inexpensive HDPE cutting boards to use for the bearings, shown in white. Another cool trick that he does is to drill and tap the ends of the brass pins so a small machine screw can be inserted to use as a handle to extract the pin if he wants to disassemble the thing.

-

@dave r said:

I don't know much more about the "old head". He's a member of one of the woodworking forums I participate on and he seems to have a vice for shop made vises. The screw is typically the most expensive part but he came up with the idea of using these cheap dumbbell handles which work quite well. He also buys inexpensive HDPE cutting boards to use for the bearings, shown in white. Another cool trick that he does is to drill and tap the ends of the brass pins so a small machine screw can be inserted to use as a handle to extract the pin if he wants to disassemble the thing.

Great stuff, are you able to share the model?

If so I might adapt it for metric and me, and share of course. Although I s'pose I could do it the hard way....

Advertisement