Problem with My Spreadsheet Help?

-

Joe,

Fixed it. Ask your local repair guy about an Excel person local to you. They could explain it all firsthand. Basically it has to do with your spreadsheet programs thinking some number are not numbers but letters. As to why this has happened, I don't have a clue. Aren't computers great?

KrisM

-

I'll check it out in the AM Kris,

I see you're a timber frame designer

That's something I've never really done is any serious timber framing.

That's something I've never really done is any serious timber framing. -

Right on Kris, you fixed it

Gracias amigo! What did you do, edit all the cells??

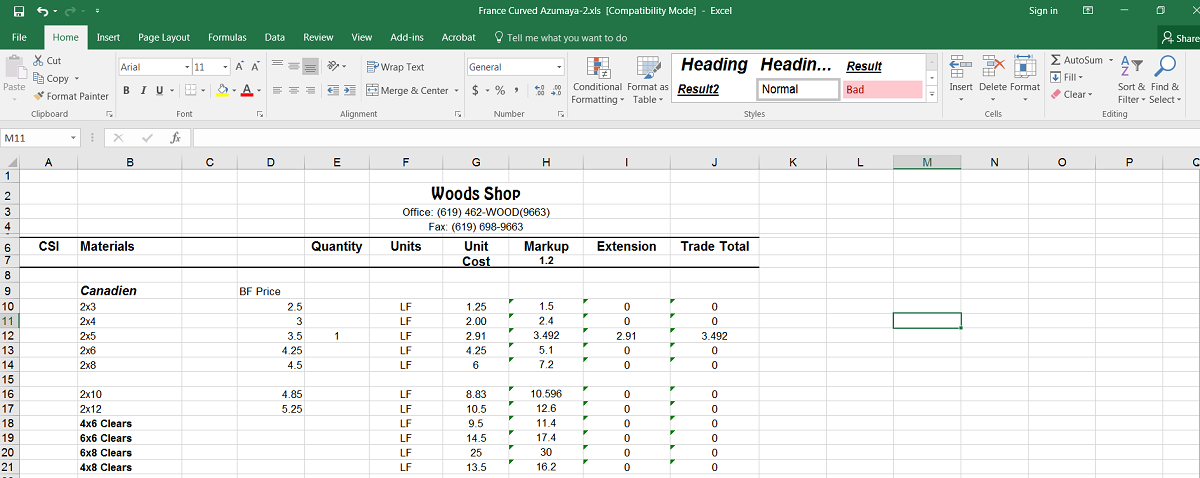

Gracias amigo! What did you do, edit all the cells??top right, what is that Result 'Bad' in the red box? I've never seen that before.

-

Joe,

Glad it works. Here's an explanation of what I did. The #value error message says that the formula is referencing cells which don't have the appropriate format. Using row 14 as an example, if you click on the cell at I14 (column I and row 14), you will see up at the top of the screen that this cell contains a formula which in this case is multiply the contents of cell E14 with the contents of cell G14. If we look at G14, we see it contains '6', a number. Cell E14 is seemingly blank. If we right click on e14 and look at the format setting, it is shown as general. This means that it can contain either text or numbers. When excel wants to use this cell in a multiplication operation as required by the formula and the cell is seemingly empty, it doesn't know what to do and gives the error message. What I did was delete the cell contents with the delete key which allowed excel to reevaluate what it wanted in that cell which it set to being a number. The cell was acting like it contained a space (a letter which you can't see). An alternate method is to type a 0 (zero) into every cell which is referenced by a formula which sets the quantity and establishes the cell as containing a number. I've attached the spreadsheet with 0's inserted everywhere that a quantity is required. Having blank cells is a bit confusing. Better practice is to have an entry in any cell which contains a number, even if that number is 0. Hope that makes sense.

The red box is displaying a setting that you can use if you want to apply a particular look to a cell (colour, text size, underline etc.). This is a setting that you can copy using the paint brush icon onto a cell that you want to look like that. Not really something you necessarily need.

You might find it useful to take a short excel course at your local college or wherever it is offered close to you. Excel is in fact quite simple and I am quite sure that you would pick it up quickly. Speaking from my own software experiences, I had to learn a new timber software which had me totally befuddled. After I was shown a few things about how it worked, it was in fact dead simple to use. Good to send your brain in a different direction once in a while.

Speaking of your timber frame skills, I would say that looking at your work, that your skillset is right up there.

KrisM

-

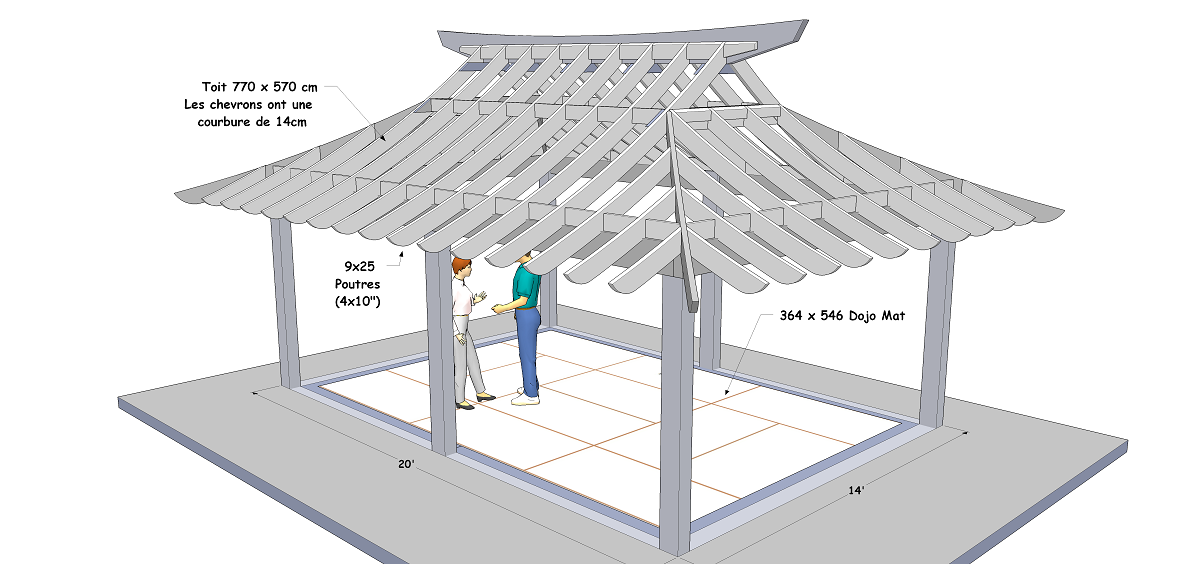

Right on x 2 Kris! Now I can work on an estimate for one of my azumaya kits going to Cannes France

Thanks for taking the time with this for me!

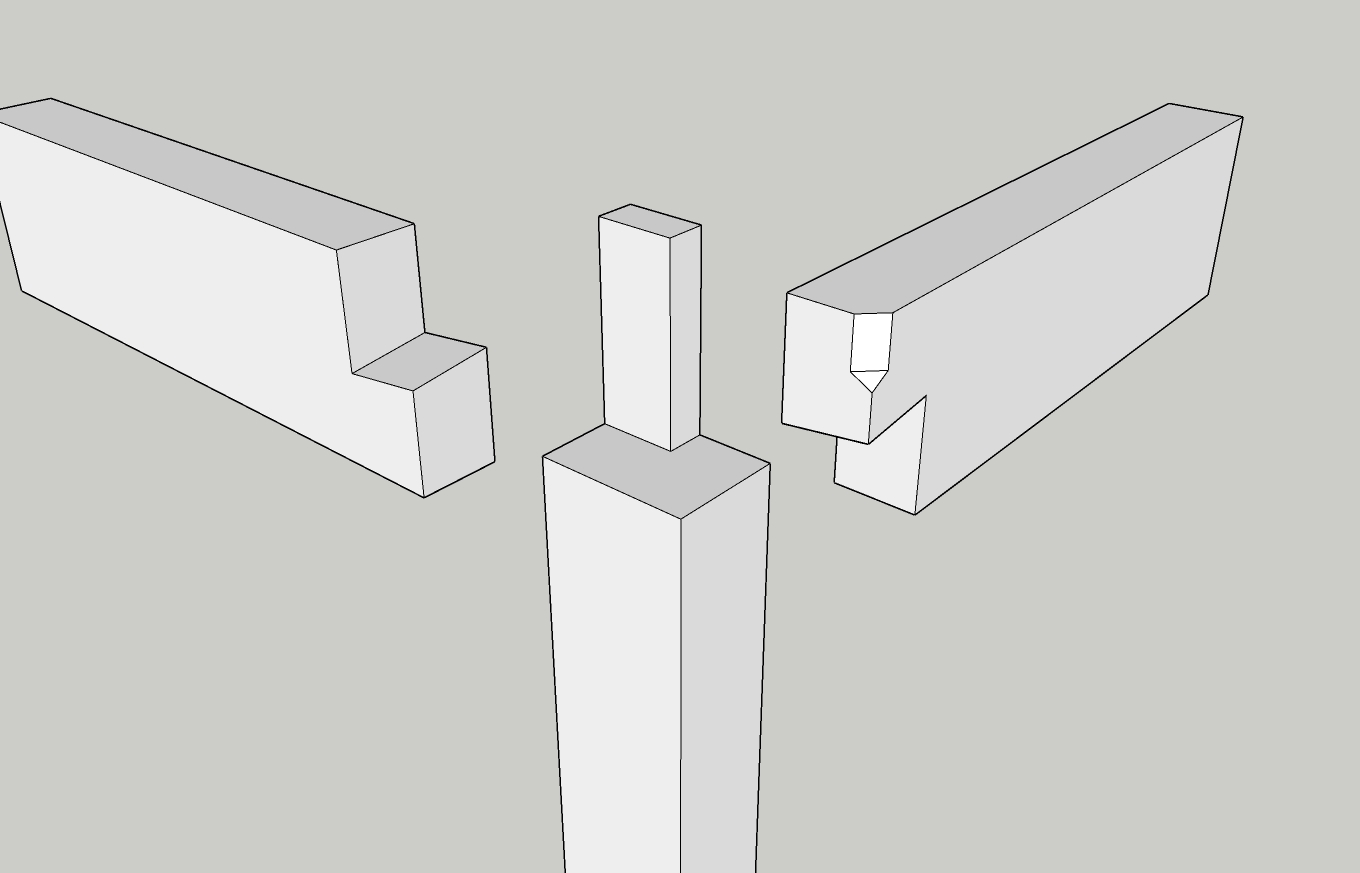

Thanks for taking the time with this for me!matter of fact, could I ask about how you'd do a post to beam connection using T framing??

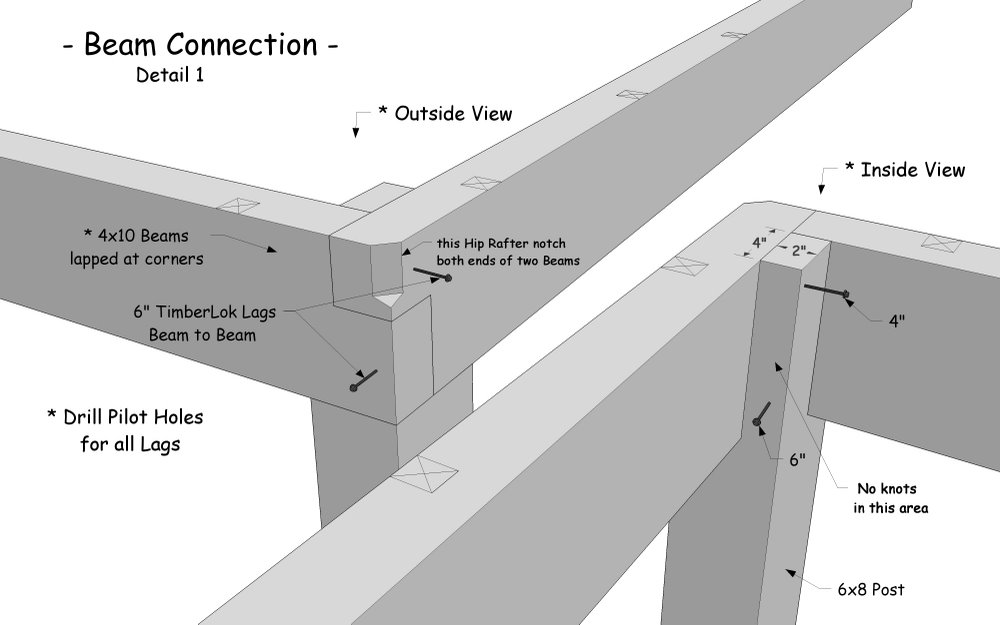

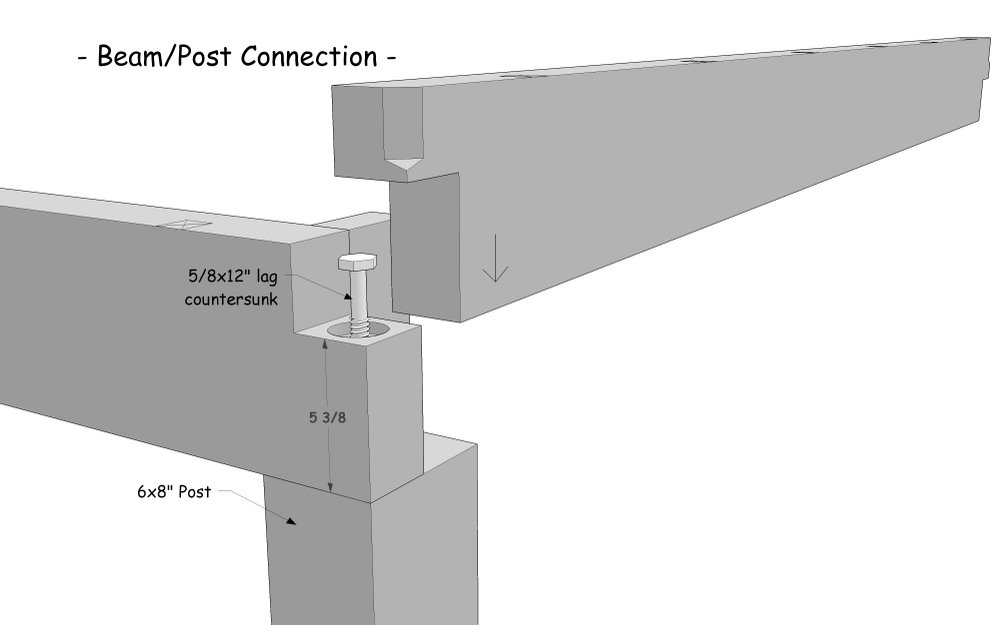

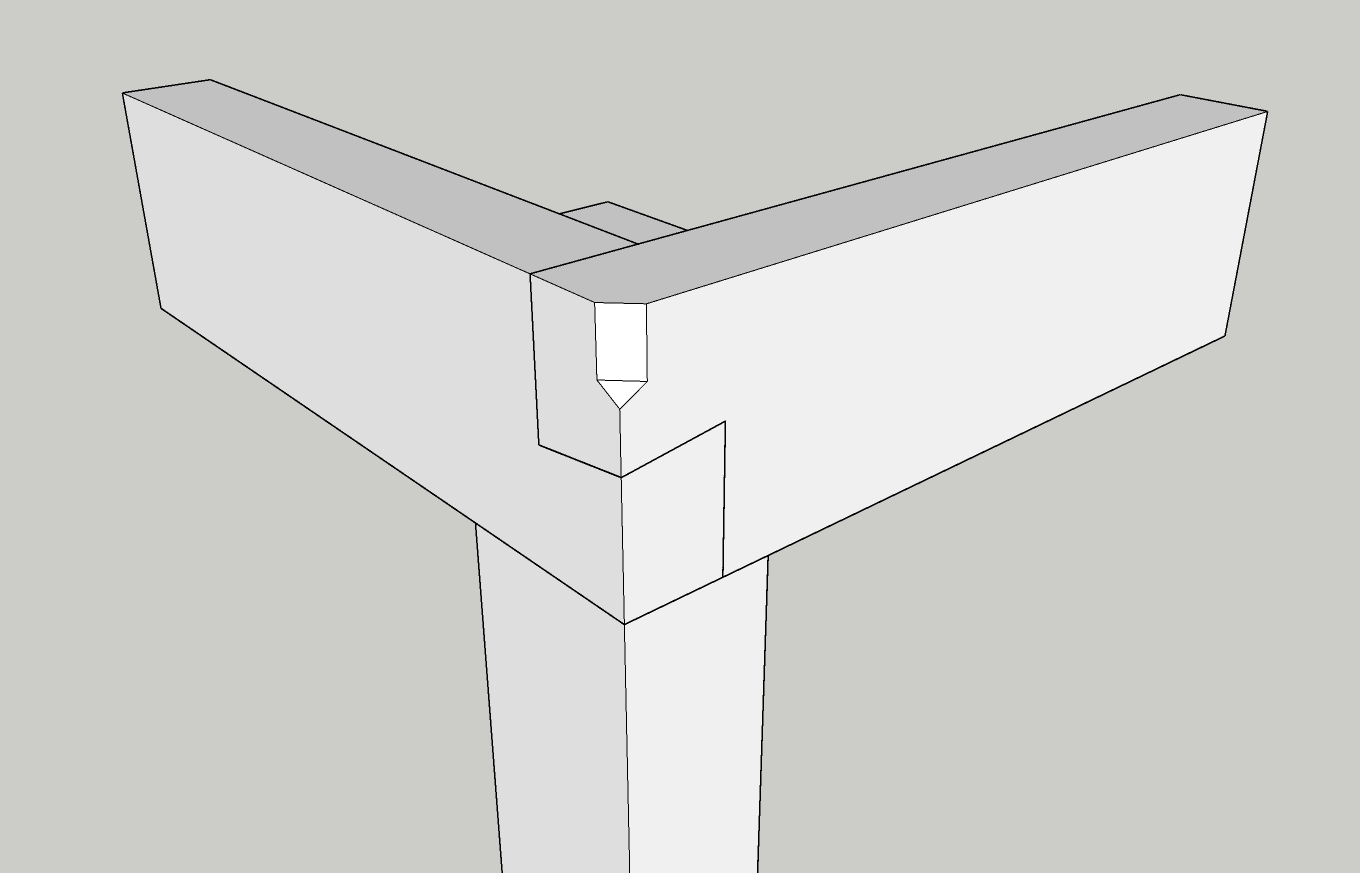

this is how I usually do it using 6x8 posts and 4x beams for my azumaya which are fairly small buildings.

this one to France will be a larger building and I just know I need a better post connection, and in France they have a long tradition of T framing and they don't want to see any fasteners!

-

This is the building Kris, around 20' x 14'.

-

Joe,

Here's one way to do it. Same half lap but the mating surfaces are on a bevel so that the weight from above locks the corner together. Put three timber screws through the beams (plates in timber frame parlance) down into the post. Two more timber screws from the bit of the post sticking up into the sides of the beams. Countersink and plug those two screws. The fact is that the timber frame industry in Europe has invented and uses a lot of metal products to make their industry more cost efficient. For example, the timber screws we now see came from products created in Europe. If you really want the whole meal deal, you could put the ends of the braces into a 3/4" deep housing and then also have a mortise & tenon connection with a peg. Authentic and strong. Also more labour intensive and costly than what you have drawn.

KrisM

-

I've thought about doing something like that Kris but not sure how i'd make those angled cuts. My normal way is using my radial arm saw and dado blade.

so you know much about the metal products / connectors used in France?

-

Joe,

You can do most of the straight cut with your radial arm saw or a skil saw. Finish the rest with a handsaw (Japanese style is my favourite). Its really not that much work.

Here are a couple of links to various metal fasteners -

http://www.specializedtimberfasteners.com/products/ (look at SFS Intec & Sherpa in particular)

http://www.timberlinx.com/ (An American company) -

Advertisement