A Useful SU to 3D printing thread.

-

How about it then?

Please anyone jump in and make a useful thread for best practices, useful tools and tricks to get an SU model to 3D print.

-

DesignSpark Mechanical (Sketchup on Steroïds(free = SpaceClaim Light)

import / Export SKP (prefer the old V1 for some more functions in modeling! )

Is perfect for any 3D Printing works! Has STL, PDF 3D export etc...

-

Hey, my specialty!

Do you have a particular project you're working on now Pete? Any specific questions?

Do you have a particular project you're working on now Pete? Any specific questions?Here's where I always send folks first, my article on MasterSketchup: 8 Tips for 3D Printing with Sketchup. This article covers the best practices.

-

Here are a few more tips that I wish I know when starting out.

-

Learn about the printing process, even before designing in Sketchup. Surf YouTube or go to a makerspace and get some hands on time with a machine. See what makes a print fail (despite the media hype, you can't print anything!) and how you can design around the limitations. I would say this is the #1 thing you can do to design effective prints, especially when using a commercial print service like Shapeways.

-

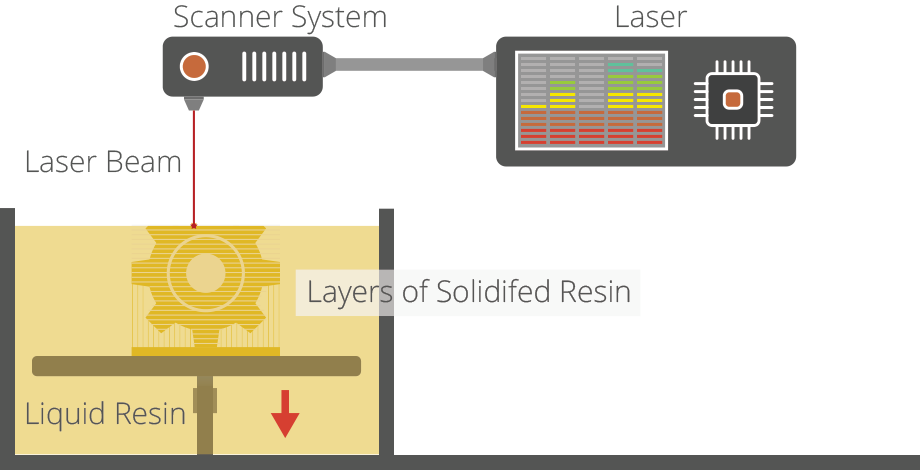

Understand that there are a handful of 3D printing processes, and that designing for each one has its nuances because of the particular way the machine works. Ie: hollowing models is great for some machines to help reduce material costs, but working with a solid block of a model may be easier on a common filament-based machine. Become familiar with each process, and decide which one will work best for your particular needs. This tip builds directly on #1.

Here's a good guide on 3D Printing Industry to get you started.

-

It helps to get your hands on 3D printed samples, so you can feel for yourself the mechanical properties of each kind of material. You can get samples from a trade show, a local makerspace, request from a manufacturer, or as a last resort buy a 3D printed part from a print service.

-

Once you know what machine you'll use, learn the "print resolution" of the printer. Similar to DPI in photos and paper printing, 3D printers have a smallest minimum feature/detail resolution that they can print at. 2mm screw threads? Probably not. 20mm screw threads? No problem! This is a very common problem when starting out because it's so easy to zoom up to 1000% on your model and everything looks gigantic, but the printer can't actually produce that detail in the real world.

-

One tip that you can use to check for minimum detail is to make a dummy cube the size you want your smallest feature to be (say 1mm x 1mm x 1mm), and then drag that cube around for size reference in your model. Importing an object to compare the overall size of your model is another good idea. Making a phone case? Import a model of the phone to get an idea of scale. BTW, did someone say 3D Warehouse?

-

Now for making your model solid. I like to work in little solid bits of solid groups or components, and then use the Outer Shell command to combine them all at the end. This way you experience less of Sketchup's quirky ability to goof up some seemingly good geometry. You can also save copies of your model at important steps along the way to create a sort of model history, enabling you to go back to a previous point in the model. Not quite parametric modeling, but as close as you can get with Sketchup.

-

Use plugins to check for errors and sometimes fix them. Thomthoms Solid Inspectors and Tig's SolidSolver are great free options. For really frustrating problems, use a 3rd party program. Netfabb Basic and Netfabb's online model repair are excellent to quickly fix an exported STL before sending it to the printer. If you're uploading models to Shapeways or another 3D print service, they have an automated fixing system similar to Netfabb that will fix minor problems.

-

-

@unknownuser said:

Do you have a particular project you're working on now Pete? Any specific questions?

I could potentially have around 12 houses that need a fast turn around from SU to solid .stl, however if I do not get that job I will need the knowledge for future anyway.

Thanks for your valued input.

-

For architectural scale models, you almost have to start from scratch or rebuild them using the existing model as a guide for the scale you want to print at. The reason is because when you scale down an existing model, you're left with tons of features that are too small to print, so you have to start over and exaggerate the size of features that are important to show, decide what needs to be left out. It's pretty easy to repeat after you've done one, because the modeling is so much simpler. I guess an analogy would be low-poly models for faraway components in a game vs. the high detail closeup objects.

Advertisement