Banca Desk

-

Great model. Nice legs...Haha

Really, good job on the table and render. I haven't thought of Sketchup when I can't sleep. I "build" enough stuff in my head at night as it is.

-

Thanks Peter.

If I didn't have to worry about waking up the family I'd be out in the shop building real stuff. At least SketchUp is quiet.

-

Nice job Dave,

Very interesting piece

Very interesting piece -

Dave,

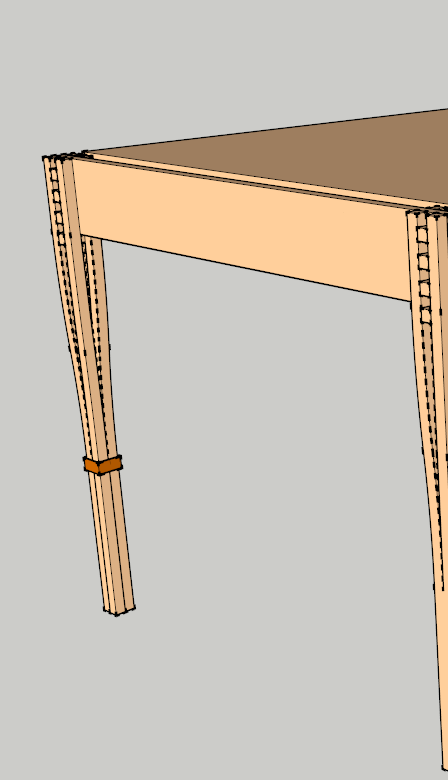

More on those legs. If the legs are four pieces glued and bent, the glue joint will be in tension. Wonder how long it takes for one of those joints to fail? If the leg is split, then the joint where the legs intersect the box jointed stretchers is in compression, so it might be stronger in the long term.

None of this has anything to do with SketchUp, of course. I'm just curious. Yours is a nice model and a nice render.

Best,

dh -

Thank you, Walt.

Thank you, David. I was thinking about those legs and figuring that my approach would be to steam them to put the bends in and reduce some of those stresses. I'm guessing Mr. Sherwood didn't do that, though. I think the hardest part would be to get four legs that are all the same.

-

I agree with David about the glue joints at the top of the legs (not good just a butt joint). I like some of

his (Torsten Sherwood) designs but I think he needs a course in wood working.I would use one piece of wood or 4 pieces glued together if you wanted to maintain grain direction.

Then use a mortise machine for the mortises and also for the tapered mortise down to where they started to taper then either chisel the rest or scroll saw then a chisel. Then for the outside taper a bandsaw. And sand to finish. I'll bet Norm and David Marks might do different though. I wonder what some would say at Fine Wood Working? -

Walt, there's no butt joints in the table and no mortises in the legs for that matter. The aprons are joined together with a box joint and the four piece of the leg are glued into the corners. Lots of face grain glue surfaces so that part would be quite strong.

I agree most of the furniture looks like it could do with some refinement. On the other hand his target audience seems to be those apartment dwellers with little to spend on furniture, litte in the way of tools and who would build it themselves. I think it's more of that 'maker' philosophy like open Desk but without the need for expensive CNC machines or really any power tools at all.

-

Dave has a point. Steaming the components of the legs would reduce the stresses where the four pieces join, as well as around the box joints.

dh -

-

Dave oh I see now

-

My first take on it was a mistake. I made all the components 3/4" thick, not 5/8".

I think I'll go back at it and do it all in 16mm parts thickness.

With white pine, I don't think there is much to be gained by taking all the trouble to bend with steam. Today's glues should hold all together just fine. There is a lot of long grain to long grain in the joinery.

The top is a floater. The project should make for a pleasant weekend in the shop.

-

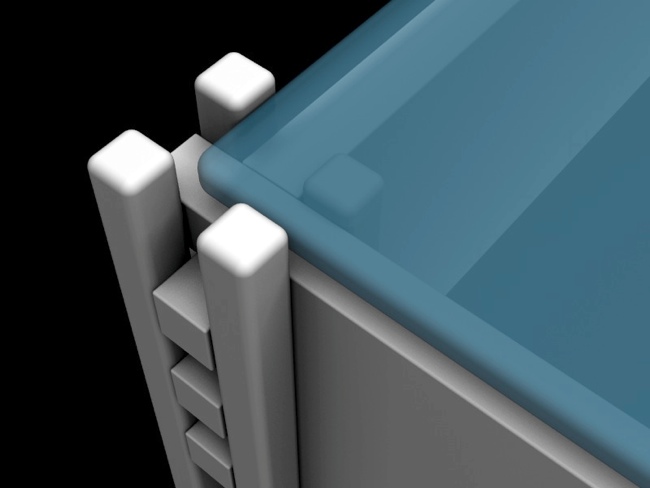

And here is a thought about those legs and whether to pre-bend.

Consider it done with a little design change, that of adding a collar of carbon-fiber tape to the legs right where the curve ends above the bottom straight segment. I'll have to see whether carbon fiber can make the 90 bend without compromising its strength. The visual can be called an enhancement.

Another option for the wrap-tie would be a 19mm length of square brass tubing. Available in 1.25" square at .100" wall thickness, it would fit snugly to the legs if the quarters were milled to precisely 16.5mm square, or right under 0.650". See this site for the brass. http://www.lewisbrass.com/tubing/square-brass-tubing-3/

A pic of one leg, wrapped thus, is shown here.

-

.

nice texturing Dave

(as in- real nice)

(as in- real nice)a glass top alternate idea for that joint-- the middle one is lower than the other 3 and provides a pad for the glass.. the other 3 keep the glass in place.

-

There is an easy way to make the legs if you the time to sort through some lumber. As this is a gentle curve, if you can find a board that has this curve in the grain and then cut it out on the band saw it should be very strong. I was taught this by an Englishman that said the shop he apprenticed in always sorted out lumber with the grain curved to use for curved legs. They especially like boards cut near the buttress of the tree as they were always curved and had lots of uses. Nice table Dave.

Advertisement