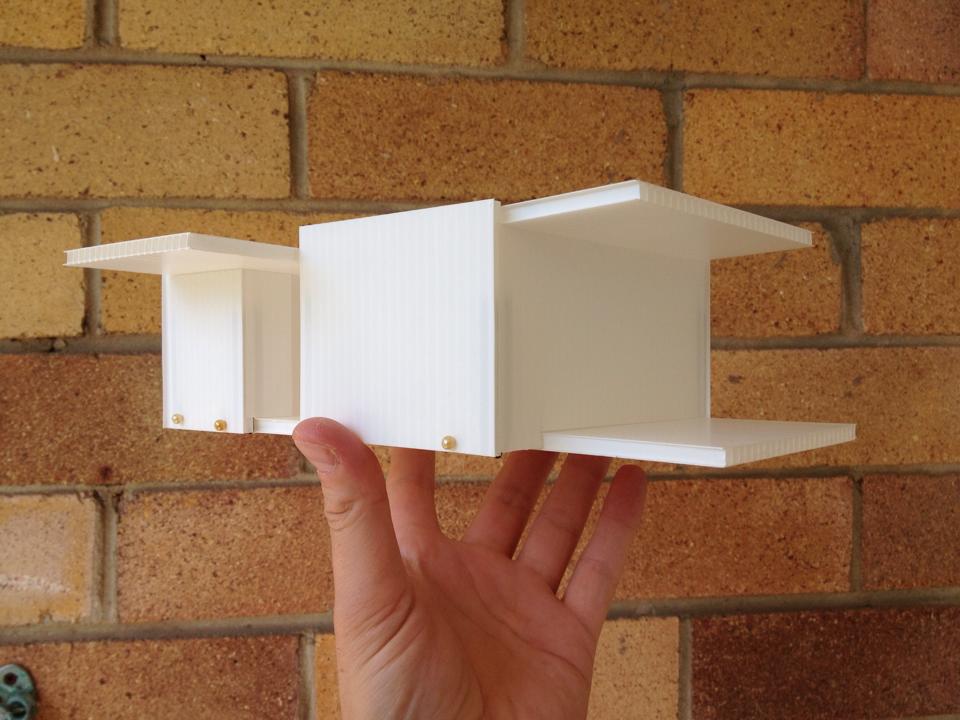

Fast, clean physical model making

-

Posted to a WIP thread but thought I'd post it here as a few may want to adopt this.

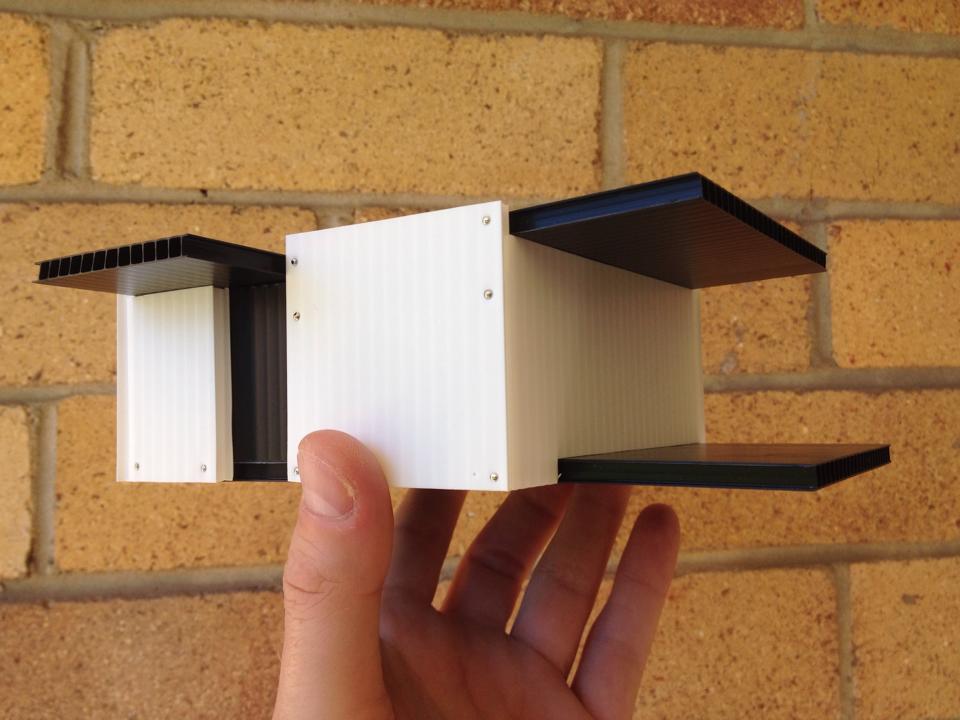

Firstly I wanted a really robust and solid physical model that could really take some punishment, so tried coreflute, though it is normally the worst medium to consider modeling with, I ended up developing a very sturdy concealed joint. This is as sturdy as tupperware, plus if I print the externals or drawing to paper I can actually wrap each wall, and the way it all clips together holds it in place!

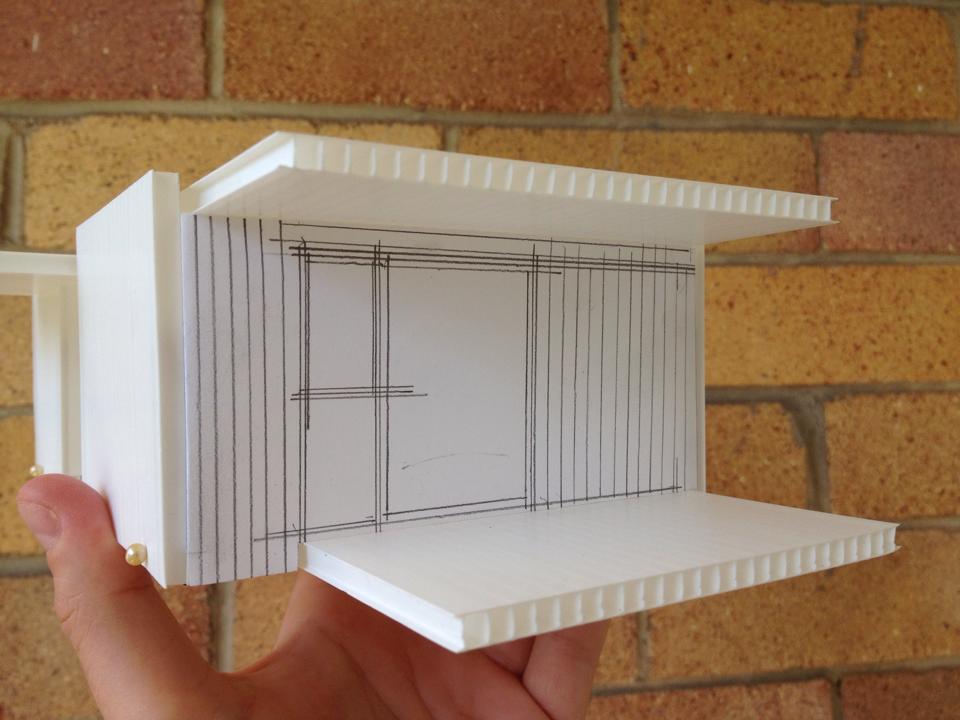

Windows can be cut in, the vertical open flutes then give a trench for a piece of cut acrylic to be snapped in!

I just need to swap out the pins with some tidy ones and presto! Very quick, clean and solid as!!!! I've dropped it a few times and it handles it without issue.

-

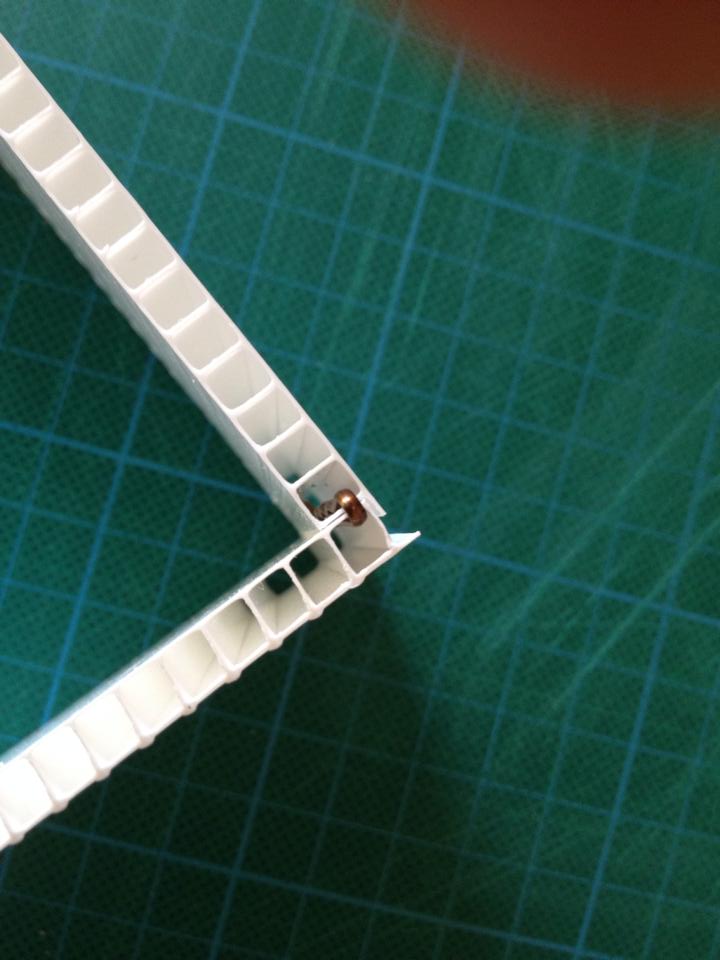

Richard: that is a fantastic approach, and one that I may have to borrow! Those sketchy wraps really work well too. One question: what are those clips you are using for the corner- joints?

Brilliant work

A.

-

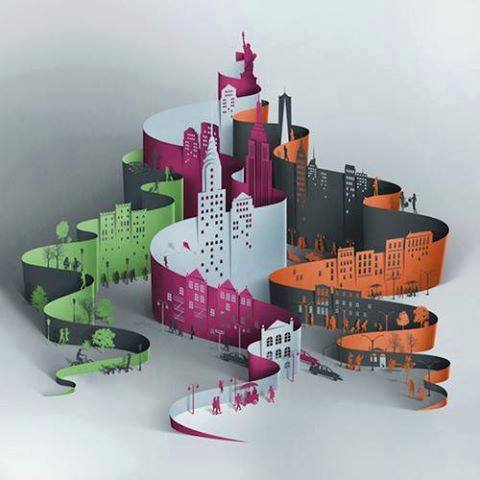

That's kool Richard. I don't ever have use to make physicals. Here's one I saw today though.

Log into Facebook

Log into Facebook to start sharing and connecting with your friends, family, and people you know.

Facebook (www.facebook.com)

-

@andyc said:

Richard: that is a fantastic approach, and one that I may have to borrow! Those sketchy wraps really work well too. One question: what are those clips you are using for the corner- joints?

Brilliant work

A.

Chicks hair clip thingys (hair pins?) They are perfect! Getting the right approach to cutting the sheets and the little flanges off is the trick. Work with a sharp blade box knife and don't rush! That little joint is the trick, all else was a nightmare!

BTW you only need to clip from the bottom, it's a really rigid connection! Use a floor internally so it can keep all in tension and it's rock solid! Also you can pull it to pieces again and again, doesn't really wear anything out!

-

@krisidious said:

That's kool Richard. I don't ever have use to make physicals. Here's one I saw today though.

Log into Facebook

Log into Facebook to start sharing and connecting with your friends, family, and people you know.

Facebook (www.facebook.com)

[attachment=0:2zjgg252]<!-- ia0 -->10300807_858012340882401_2647670567344721659_n.jpg<!-- ia0 -->[/attachment:2zjgg252]

Mate that is AWESOME!!!!!!!!!!! Some people are way beyond creative!

-

I thought they looked like hair-clips.... but didn't want to say in case they turned out to be some specialist fitting and I looked like an idiot

I thought they looked like hair-clips.... but didn't want to say in case they turned out to be some specialist fitting and I looked like an idiot  Yep, that joint is a very neat solution. And I love the idea of slotting windows into the flutes. I occassionally need to make quick mock-ups not dissimilar to this. I'll definitely be trying your method next time. Thanks for sharing.

Yep, that joint is a very neat solution. And I love the idea of slotting windows into the flutes. I occassionally need to make quick mock-ups not dissimilar to this. I'll definitely be trying your method next time. Thanks for sharing.A

-

I love the hand drawn bits on the 3rd image....it reminds if the stuff we did in the 70's

Whilst I still have to occasionally pinch myself when I think of the 3D modelling and rendering we do now, there is still something very 'honest' about a raw and tactile hand made physical model.

It won't be long before we all have a 3D printer on our desks....and, just like Architectural Illustrators, the professional Model Makers will slowly be forced into retirement.

-

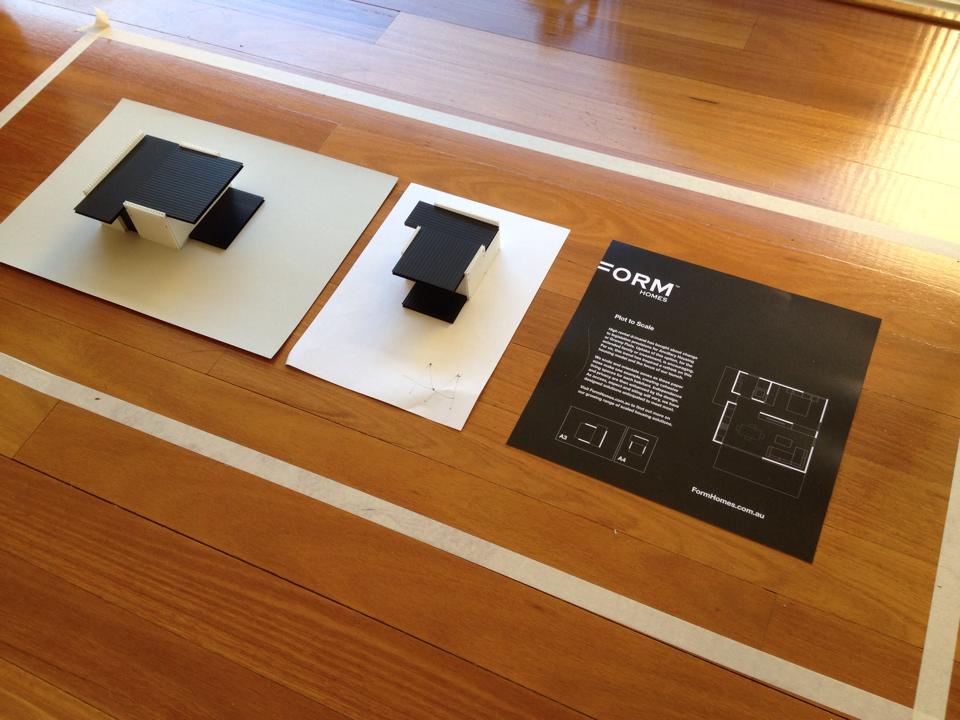

The final models for the exhibition. Ended up pinning all, the black v white coreflute made then rather striking!

-

Looks great Richard.

-

@krisidious said:

Looks great Richard.

Thanks mate! The two models and plaque are block mounted on 8mm boards to sit on a 1200 x 500mm plinth.

-

Thank you Richard, another great idea to put in the toolbox, and you've invented the flatpack model too! I'm starting to travel my ideas around and this should be useful

Advertisement