A side-table with legs strong enough for 2 big mamas

-

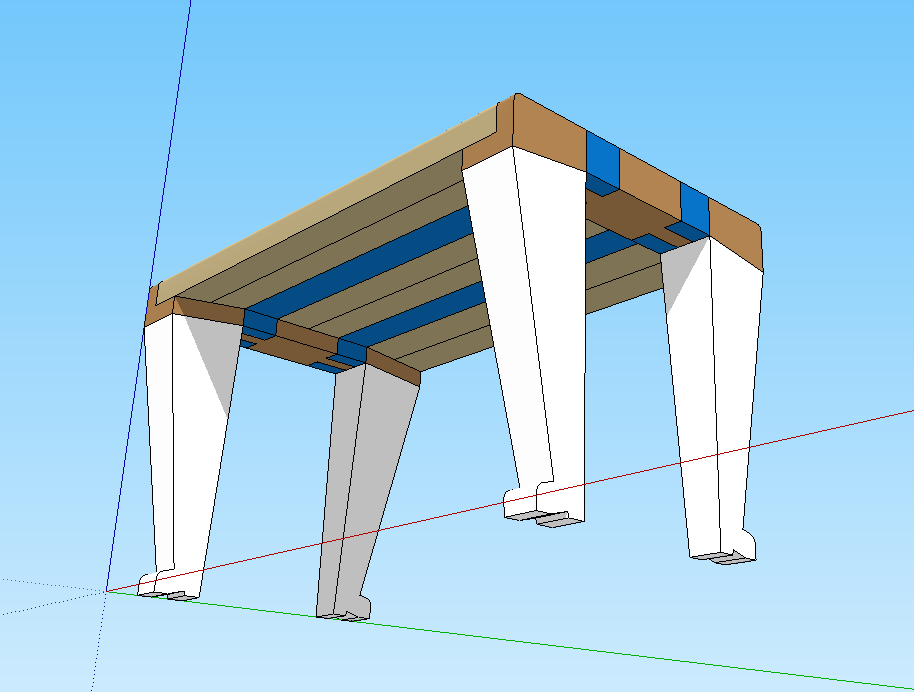

I have drawn a table and I'd really like to hear what you think about it. Especially about the way it is assembled and from someone who has already built some tables in a real shop in a real life.

The idea in general was to create a solid table where I like the bottom side of the top more than I usually do. And well, I like it, but I am really not sure whether I am simply too optimistic as far as the laws of nature/wood and the solid thing are concerned.

-

Well, those legs are kind of homely, aren't they?

The construction as you've drawn it is needlessly complex. Getting everything to fit properly would be a huge undertaking. I don't think you'd be able to get those keys installed in the tenons in the legs. It looks like you've create some potential problems for wood movement. Because of the way the pieces shown in blue wrap over the ends and are trapped in notches, when the two center pieces expand they will put stress on the blue pieces. The outside pieces will expand outward and you'll end up with an unsightly ridge where these pieces are drawn flush with the ends of the end pieces.

Even if you can get all that crazy joinery to fit tightly to begin with, I don't believe it will stay tight. You should study traditional joinery methods used in large tables. Those methods are still around because they work and because woodworkers can make them.

-

@dave r said:

Well, those legs are kind of homely, aren't they?

Well, yes.

@dave r said:

The construction as you've drawn it is needlessly complex. Getting everything to fit properly would be a huge undertaking. I don't think you'd be able to get those keys installed in the tenons in the legs. It looks like you've create some potential problems for wood movement. Because of the way the pieces shown in blue wrap over the ends and are trapped in notches, when the two center pieces expand they will put stress on the blue pieces. The outside pieces will expand outward and you'll end up with an unsightly ridge where these pieces are drawn flush with the ends of the end pieces.

Even if you can get all that crazy joinery to fit tightly to begin with, I don't believe it will stay tight. You should study traditional joinery methods used in large tables. Those methods are still around because they work and because woodworkers can make them.

Everything you are saying is probably correct. Although I have to admit that I thought a CNC router's precision would make it at least really easy to assemble such a thing in the first place. Guess I need to build more than just my nifty bike stands...

-

Even with CNC you won't be able to get those keys installed in the legs and no amount of digital control in manufacture will make up for seasonal wood movement.

-

@ttype said:

I have drawn a table and I'd really like to hear what you think about it. Especially about the way it is assembled and from someone who has already built some tables in a real shop in a real life.

The idea in general was to create a solid table where I like the bottom side of the top more than I usually do. And well, I like it, but I am really not sure whether I am simply too optimistic as far as the laws of nature/wood and the solid thing are concerned.

[attachment=1:3c385125]<!-- ia1 -->Wellassorted.png<!-- ia1 -->[/attachment:3c385125]

Hi,

I have made quite a few tables, including ones with breadboard ends (which is effectively what you have designed). There are some problems with making your design from wood.

The biggest problem, as Dave R has noted, is that you have to allow for seasonal movement between the width of the top pieces and the length of the end caps. Typically wood will change width by about 1% through the course of the year. This movement poses problems for your design.

If you try to glue the top boards of your design to the end cap + leg assemblies, either the top will split or the joint will tear apart. So, if you can't glue the joint between the top boards and end caps, the only thing holding the end caps onto your top is the notches in the blue boards! If the table gets an endwise shove while carrying weight, the leg assemblies will fold under and the table will collapse! Also, those notches are themselves a problem, because there is no space for the two tan boards between the blue ones to expand.

Here are some ideas: If you can stand the look, you could add apron boards lengthwise between the legs. These would both keep the ends together and would provide greater resistance to wracking. As an alternative, you might bolt the ends onto the top (using elongated holes to allow for movement). You could countersink and plug the ends of the bolt holes to conceal them (though then you can't tighten them if things work loose).

As a picky point, how were you planning to install the lock pins in the tenons that join the legs to the end boards? The holes don't reach either face, so there is nowhere to drive them in! Also, there are some spurious blocks inside the joints that don't have notches in the corresponding top boards.

Steve

-

@slbaumgartner said:

As a picky point, how were you planning to install the lock pins in the tenons that join the legs to the end boards? The holes don't reach either face, so there is nowhere to drive them in! Also, there are some spurious blocks inside the joints that don't have notches in the corresponding top boards.

Steve

I don't think those are picky points but evidently not important to ttype. He said it'll be built using a CNC router which I gather he thinks will solve the problems. It'll be interesting to see his finished project. I hope photos will be forthcoming.

Advertisement