Laser Cutting

-

We have 2 laser cutters at our Uni workshop. My students use it to cut planar forms for making arch models. It is quite straightforward use . We usually generate dwg or dxf or illustrator file which drive the cutting. We use it to cut acrylic and mdf mostly.

-

@sepo said:

We have 2 laser cutters at our Uni workshop. My students use it to cut planar forms for making arch models. It is quite straightforward use . We usually generate dwg or dxf or illustrator file which drive the cutting. We use it to cut acrylic and mdf mostly.

Have you ever used it to cut balsa wood and what is the wattage of the laser you use?

I have seen a 40W Co2 laser cutter for a reasonable price. However for materials like balsa it can set them on fire apparently.

-

Not sure what the wattage is before asking our technician. I can tell you that it leaves burn marks on the mdf edges, albeit nice and sharp.

-

I've got a friend who used it to make quite a bit of jewelry and wood boxes with ornate designs. It looks pretty good. It does burn the edges, but that's kind of cool looking. I'm not sure but I think she was using bass wood.

-

Liam, look for a hackerspace or Fablab near you. Also called makerspaces, these are places you can pay a membership to access advanced tools, much like a gym.

I'm a member of a makerspace in Minneapolis, and I can't recommend it enough. We have a laser cutter, CNC router, RepRap 3D printers, CNC plasma cutter, welder, and lots of other tools available. The energy at these places is a great benefit too, as you can see what other people are making and ask/answer questions much like these forums but in real life.

-

@d12dozr said:

Liam, look for a hackerspace or Fablab near you. Also called makerspaces, these are places you can pay a membership to access advanced tools, much like a gym.

I'm a member of a makerspace in Minneapolis, and I can't recommend it enough. We have a laser cutter, CNC router, RepRap 3D printers, CNC plasma cutter, welder, and lots of other tools available. The energy at these places is a great benefit too, as you can see what other people are making and ask/answer questions much like these forums but in real life.

Wow thanks so much for this link, I am going next Tuesday for the open night and they have loads of equipment http://hackerspaces.org/wiki/London_Hackspace

I had some disappointing news from makerbot, I spoke to them yesterday and they dont sell printers on finance and said to use a credit card.

In the UK we dont really use credit cards and if I did get one would not have the limit needed to purchase the printer

booo. Will have to save for a few months now.

booo. Will have to save for a few months now. -

I use Sketchup at work almost exclusively for creating designs for our laser cutter.

Balsa should be no problem - you'll get the charring that other folks talked about, but I've never seen balsa, ply or MDF ever go up in flames!

You must, be careful with certain composites (pliy, MDF etc.), though. You need to look for a local supplier that supplies these materials certified as suitable for laser cutting.

That's because of the glues and resins used to hold the composites together - some will release rather toxic fumes when you cut them.

Most suppliers of laser machines will also supply suitable materials, as using the right materials makes their machines more tempting. They will be able to, say, choose a suitable wood for nice embossed "nranded" effect engraving.On our 60W machine, I can successfully cut acrylic to about 12mm thick, and maybe a little less for MDF - knock off maybe a millimetre or two for a 40W machine But the power isn't always the limiting factor here - the beam has to be focused by lenses in the cutting head, so the kerf is actually a very narrow cone. So if you need tight fitting joints, you can run into problems with the cut edges not being quite square on thicker materials.

And if you're getting a machine of your own, don't forget to allow for some good fume extraction. Any wood product is going to make a hell of a lot of smoke when it is cut!!

-

@tomasz said:

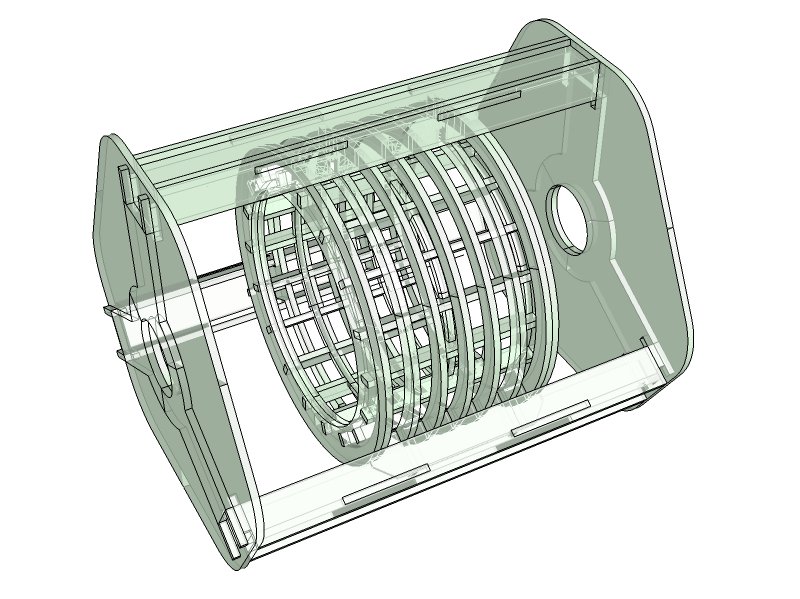

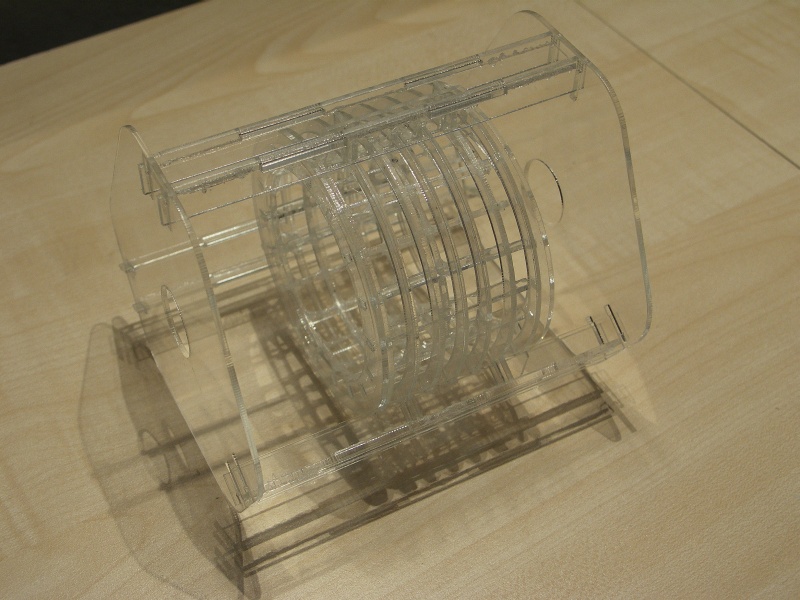

I have had tried it.

It is cheaper than 3D printing.

Here is a model in SU and an assembled model. I have received a quotation for 3D printing - ca. 200e. I decided to lower the cost and remodeled the contraption for being cut it in 2mm acrylic. I have paid ca 20e for material & cutting.The smell is awful. I have had to keep the cut parts outside my apartment for a day, just to let it vent well. Other than that - it is a lot of fun to assemble your own design

Awesome!

What is it?

-

It was a prototype of a motor. It is not shown complete here, just the external envelope. There was an inner acrylic shaft with a rotor assembly, plus those fancy triangular finishes visible in SU model.

-

I have tried it.

It is cheaper than 3D printing.

Here is a model in SU and an assembled model. I have received a quotation for 3D printing - ca. 200e. I decided to lower the cost and remodeled the contraption for being cut it in 2mm acrylic. I have paid ca 20e for material & cutting.The smell is awful. I have had to keep the cut parts outside my apartment for a day, just to let it vent well. Other than that - it is a lot of fun to assemble your own design

-

Waterjet cutting is also a option with balsa wood. Edges will not be that exact if comparing to laser, but no charring

http://www.wardjet.com/applications.html

Advertisement