Asking for modelling help with a ring design

-

Hi everyone!

I'm new to this forum and to sketchup. I started to teach myself the basics last Friday, and am now in the middle of my first actual model. It's a ring design that I've had in mind for a few months, mine and my girlfriend's engagement rings as a matter of fact

Now the tricky part is to get it pulled out from my mind and into a digital, more useful format. It was harder than I expected and I hope that one of you more experienced users could give me a few hints or guidelines on how to proceed.

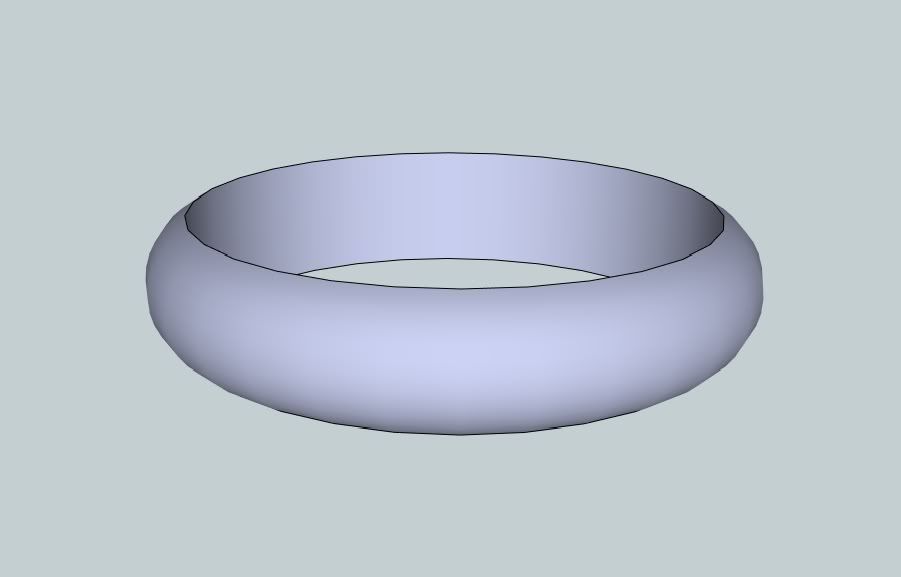

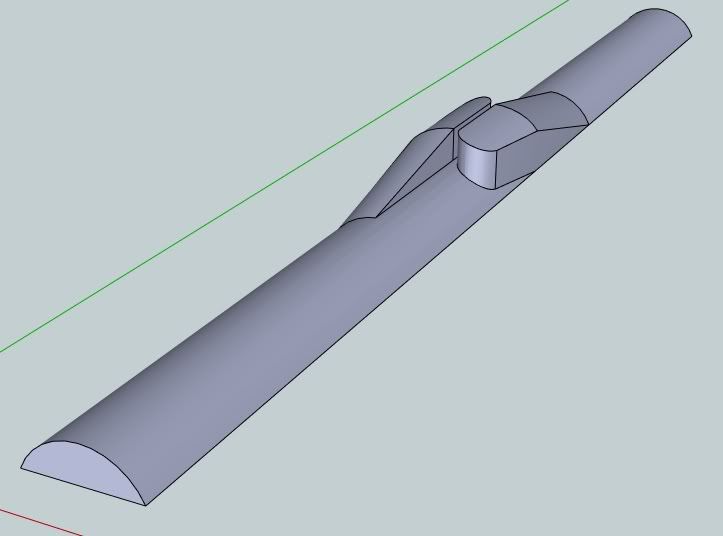

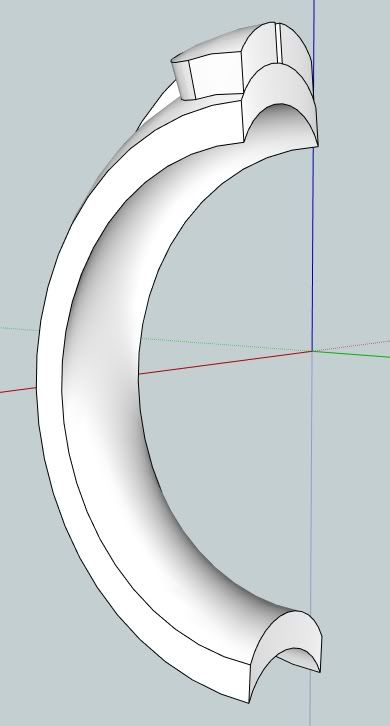

Now the tricky part is to get it pulled out from my mind and into a digital, more useful format. It was harder than I expected and I hope that one of you more experienced users could give me a few hints or guidelines on how to proceed.So my idea is to create a basic curved ring like this:

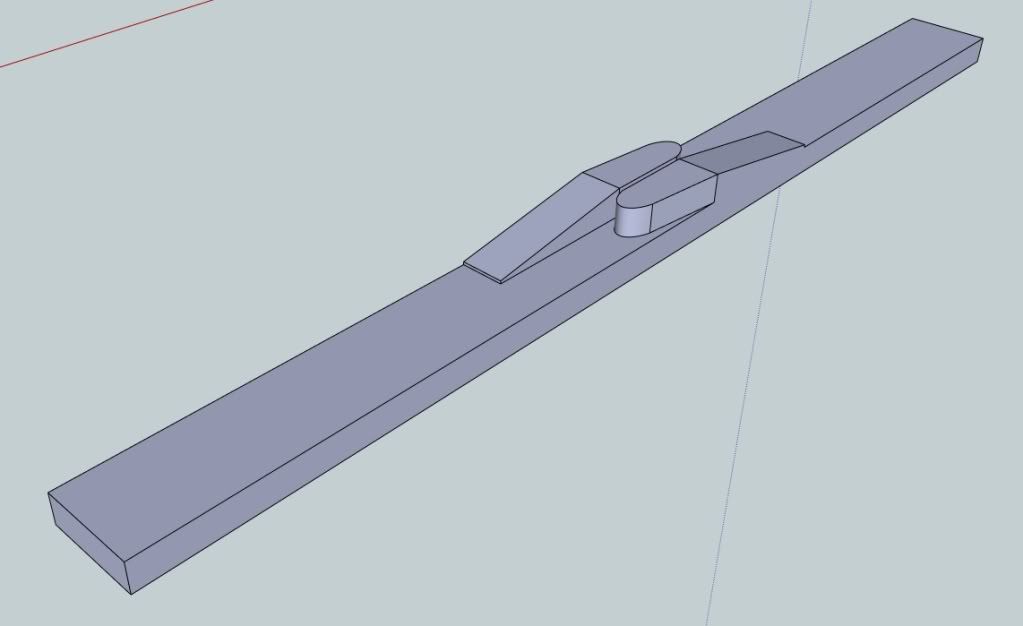

But with this pattern on top of it:

The problem is of course that I can't do anything on a curved surface, and especially not on one like this which is curved on two axes. Now, the second image is exactly how I wish the ring would look like, with the right measurements and everything, it's just that it isn't bent in a circle or curved on the y-axis. I've tried to bend the straight model but can't find any functionality for it. I've also tried to make the pattern onto the curved model, but that seems impossible without losing faces on the way and generally bugging up the model. I even tried the plugin Joint Push Pull by Fredo6 without any particular success. Now I'm out of options and hoping the someone here can help me out.

Best regards to you all!

-

Looks like at least part of your problems are due to scale. SketchUp does not like small features. Try modeling at 100x scale, when you are done modeling you can convert the ring to a component and then scale it to the real world size.

Congratulations by the way.

good luck

Ogan -

Very cool design. I designed my wife's engagement ring as well, but didn't know SketchUp very well at the time so took a napkin sketch to the jeweler. Fortunately it was enough for him. Have you tried Shape Bender by Chris Fulmer?

-

You can do that with the Shape Bender plugin. You'll need to scale up by 100 or 1000x, like Ogan suggested, then use Shape bender first on the short axis, then rotate the component and bend along the long axis. To make a complete circle, you'll need to make the long bend in 2 parts, because Shape bender doesn't work on a full circle...just split the model in half, then bend each part and put them back together.

Its a lot of messing around, but definitely doable. Congrats!

edit: Wyatt posted just before me...

-

@d12dozr said:

edit: Wyatt posted just before me...

Yes, but you provided a lot more information. I'm sure he'll appreciate the tips you gave.

-

While you are at it, be sure to reverse faces. Best wishes to you and your girlfriend.

-

Thank you very much for all your tips!

I'll be sure to check this plugin out later today and get back to you with the results.

I'll be sure to check this plugin out later today and get back to you with the results. -

Hi,

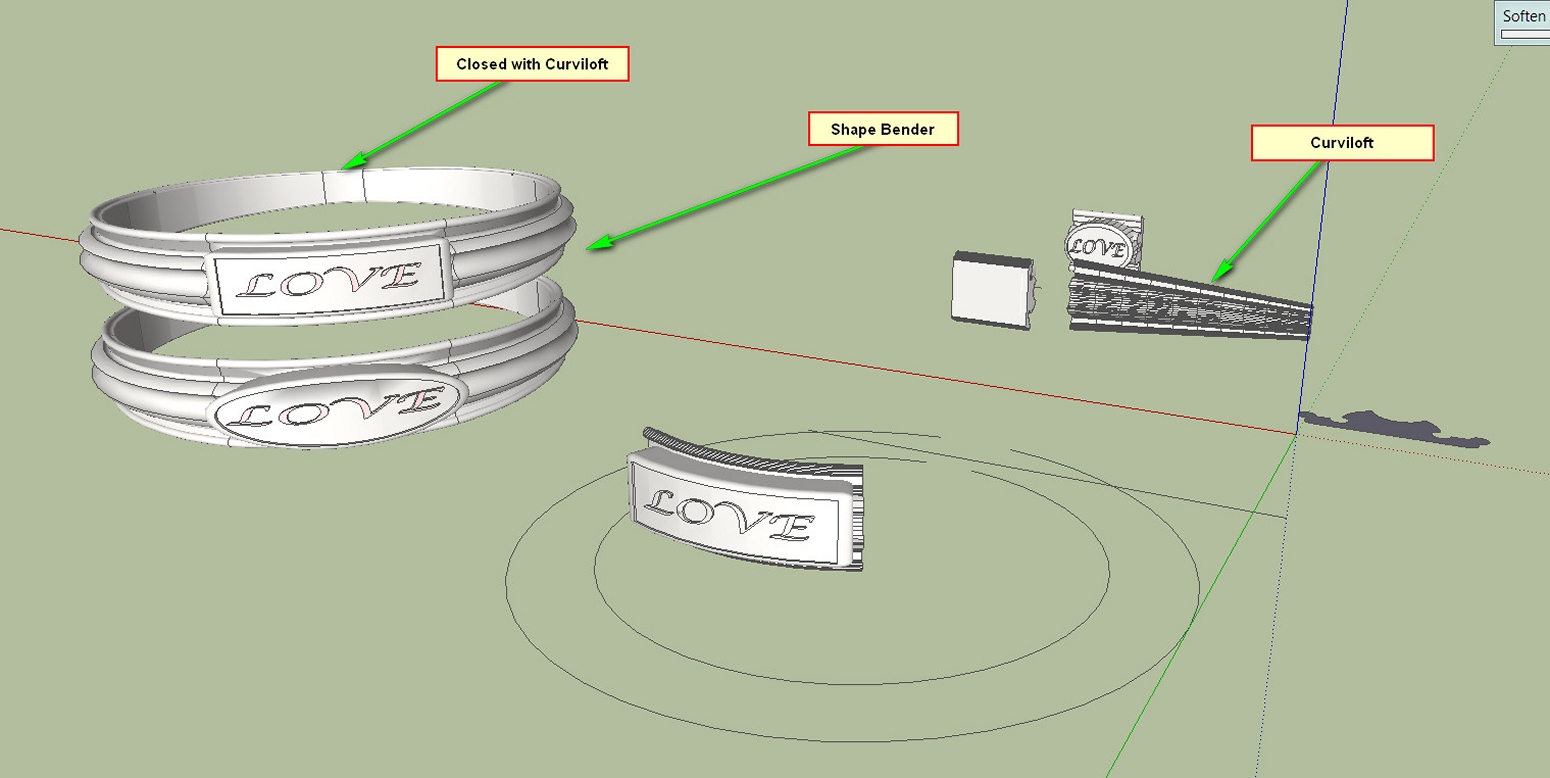

I made this some month ago with Curviloft and Shape Bender.

-

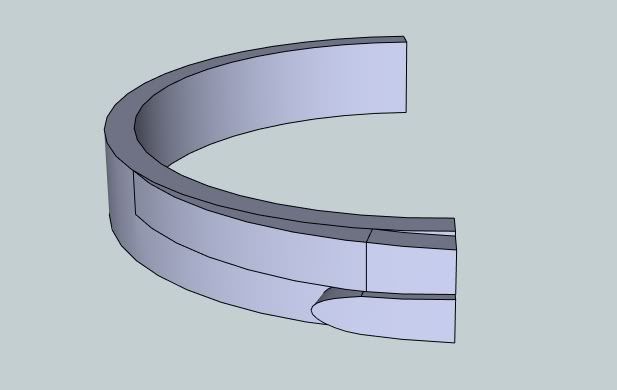

Alright, now after quite a few hours of fiddeling I'm stuck again. It seems like Shape Bender is a great tool for this purpose, but I could use some help to finnish it up. I have no problems anymore to bend the straight model lengthwise:

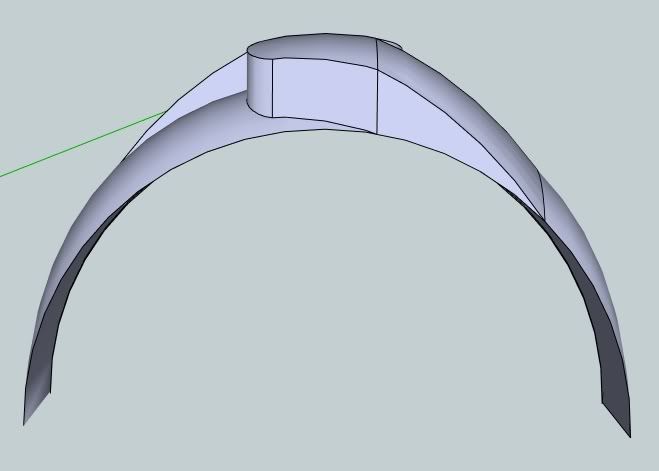

... or widthwise:

But once I try to bend it twice something wierd happens:

You see it? At the middle of the ring it somehow decides to bend the other way. I don't understand why, and I've experimented a lot to make it work. Maybe some of you guys will have better success.

And thank you charly2008 for the curviloft plugin! I've installed it, but I don't think it will become handy until the ring is ready to make whole again.

I've attached the .skp file for easier view of the problem. Thanks in advance!

-

Here's another interesting problem, probably caused by the same reasons as above:

If the ring had only kept its original shape and not narrowing down the thickness I could probably have used Curviloft to close it since the "back" of the ring is completely smooth. I really hope that you can help me solve this problem.

-

Hi, Belaar:

It still seems you are working at a very tiny scale. Small objects such as a ring would benefit from scaling up by several hundred times. I am not sure if the tiny scale is affecting the bending, but this is one feature that you should consider. Some folks use the technique of proxy components for modeling fine detail. Make your ring a component. Move/Copy it. Scale up the copy. Make modifications to the upscaled copy. Everything you do to the big version happens in the small version. When finished, delete the big version. This is a favorite technique by DaveR. -

mitcorb - It looks like its already scaled up by 1000, so that shouldn't be a problem, but that scaling tip is helpful.

Belaar - I think you may have the order in which you're doing the bending mixed up. Also the orientation before bending is critical, and perhaps confusing. Please see the attached SU file for a better explanation - use the scene tabs to view each part.

-

Ok. I stand corrected.

-

Wow! Thank you so much d12dozr for taking your time making that tutorial for me! You solved all my problems! The ring is finally done. I made it a bit different than people here suggested because I was afraid that splitting the ring and mending it on the middle of the decoration would not only result in two mendings, but would also probably prove more difficult. I made the arc, but I made the line for it 1 mm and the radius the size of my rings diameter, which resulted in a circle with a 1 mm broken line. I then bent my shape around it and mended the small crack in the ring with curviloft. I smoothed the lines left from curviloft, and now the only thing that is tells of the mended part is a small shadow that I can't remove.

What I would finally like is for someone to have a look at the finnished ring and see if the model is broken in some way that I can't detect. I only notice the shadow, but I can't be sure that I realise the implications of it. After I get the approval here my intention is to head to Shapeaway and print it out in silver, and if the model is broken the printing might fail.

I will also post the model on Shapeway's forum asking if the model follows the guidelines for silver printing, so that's not my concern at this moment.

Attached is my .skp for the finnished ring, and I promise I will also post a picture of the ring when it finally arrives

-

Glad it helped, Belaar! I'm always excited to see people using Sketchup for 3D printing.

Good thinking about using Curviloft to fix the tiny bit

I'm also familiar with printing from Shapeways, and the only thing I would suggest is to add a small radius to the top and bottom edges so the final model isn't sharp. It might be easier to do that before bending.

I made a couple comments in the attached model about the smoothing and making the model ready to send to Shapeways.

Advertisement