Modeling for plywood construction

-

I find this annoying, but the only place it's ever affected something I've built is putting it down as underlayment for tile. I've had two pieces of slightly different thickness fail to butt together smoothly, and that caused me a bit of fill work with a putty knife.

And OSU is particularly bad about being one thickness at the edges and another in the center.

No associated SU problems, though...

-

domestic plywood is manufactured in standard dimensions, ie. 1/4" 1/2" 3/4"

imported plywood is manufactured in metric dimensions, ie. 5.2mm 12mm 18mm.

upon a closer look the measurements are not equal. 3/4" = 19.5mm

why is imported plywood thinner than its domestic counterpart?

some people argue that imported plywood is undersized in comparison to domestic so that the manufacturer can put more metric plywood in a shipping container while still calling it the full standard measurement. for example the difference between domestic and metric 3/4" plywood is 1.5mm. take a 10' tall container and that translates into 14 extra sheets of metric plywood in the same cubic volume of space that domestic plywood occupies.

call it greed, call it efficiency, call it capitalism, call it whatever you want to but, all things being equal, the major difference between imported and domestic plywood is the quality and closely related to that is the price. it would be subjective to say that imported plywood is poor quality so to remain objective i'll just say that domestic plywood is produced with a smaller allowable tolerance where imported plywood has a bigger tolerance.

the easiest way to deal with imported metric plywood dimensions in your SU drawings is to use the metric dimensions that the plywood is manufactured with.

here are the sizes that metric plywood is produced in with the standard equivalent next to them.

metric- standard

2.6 mm - 1/8"

3.0 mm - 1/8"

5.2 mm - 1/4"

6.0 mm - 1/4"

9.0 mm - 3/8"

12.0 mm - 1/2"

15.0 mm - 5/8"

18.0 mm - 3/4" -

@titmas said:

....while still calling it the full standard measurement.......

Make that American standard.. the rest of the world realised the benefits of using a base ten measuring system when you use a base ten number system decades and decades ago.

Despite the excuse that it would "confuse" people to switch to metric the real reason is that the metric system was invented by the French. The yanks don't like the french... then again they did release it as "Harry Potter and the Sorcerers Stone" because the movie exec's thought Americans were stupid enough to think that it was a 'intellectual' movie if they called it "Philosophers Stone".

Has anyone seem the American version of the film? Did they dub in 'sorcerers stone' whenever it was mentioned?

-

interesting viewpoint, Hazza.

personally i am torn between the two different systems of measurements.

standard is ingrained in my brain from early childhood and for some types of measurements and functions its easier to compute than metric. ie, dividing 12 into whole numbers is easier than dividing 10 by the same number.

however metric provides much more precision,especially when dealing with measurements less than 1 inch.

in cabinet making most of the hardware is European made so its better for me to build my cabinets based on metric sizes so that the hardware functions as a system with the cabinet boxes and not as a separate item.

-

Feel free to ignore my rants, every now and then one of my buttons gets pushed, you just happened to push the "USA is the centre of the world, you should view everything said by anyone from American view point" button.

The worst case of that is web sites that do not allow you to select anything but a US state, they don't even have a "Outside USA" option.

-

don't be ashamed about your love of all things American. i think its great when i find something on the web that has not given into the world wide community mentality.

-

I just got out the calipers and from one side to the other on a piece of "3/4" plywood, it measured 0.704 on one corner and 0.660 on the other. I don't know where it was made.

I've heard about the metric equivalents always being smaller before, but I'm not persuaded. I think it is more like calling a board which is 1 1/2 x 3 1/2 a 2x4.

The highest quality ply I've used is imported from Finland, so I wouldn't make any statements about point of origin and quality.

-

SchreiberBike,

ive found plywood from Canada and the US to be of a higher quality(read:overall consistent thickness) than plywood from China. and even further than that, different suppliers may have different quality standards.so what type of things do you build?

-

I just got out the calipers and from one side to the other on a piece of "3/4" plywood, it measured 0.704 on one corner and 0.660 on the other. I don't know where it was made.

Exactly why I can not understand folks spending money on the "plywood" bits for the router. When I'm drawing stuff made of ply, I just use the nominal thickness, when using ply in the shop, if I'm housing the ply in a groove etc, I'll actually mark the groove onto the workpiece using the actual piece to be housed. Then I'll make the cut using a dado stack or router bit that undersized and make two passes.

-

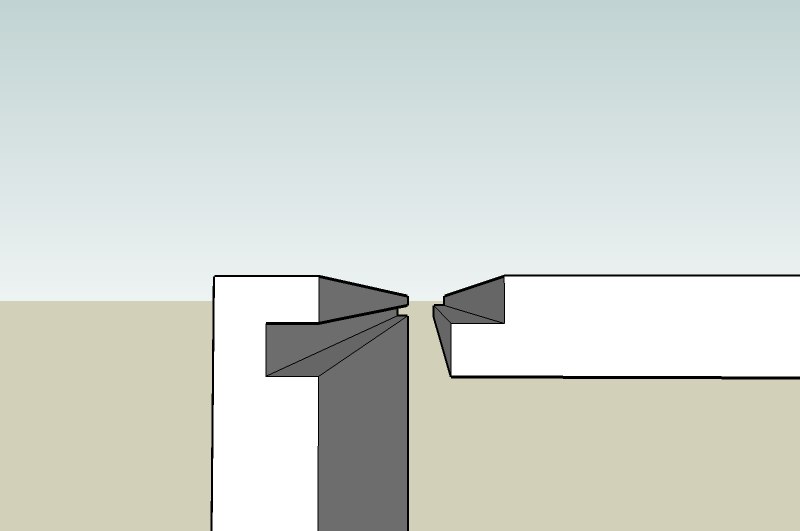

even though i have a set of undersized plywood router bits i prefer to cut a 3/8" rabit and set it into a 3/8" dado. we have a dedicated TS set up with a 3/8" dado cutter and use it more often than full width dados or dowels to join ply to ply.

-

@titmas said:

even though i have a set of undersized plywood router bits i prefer to cut a 3/8" rabit and set it into a 3/8" dado. we have a dedicated TS set up with a 3/8" dado cutter and use it more often than full width dados or dowels to join ply to ply.

How do you rabbet the plywood edge. If I rout it from the top, it doesn't eliminate the inconsistency.

I have thought about hanging a thick slotting bit below a guide bearing and removing from the side opposite the router, but I worry about trapping the wood and getting kickback,

-

most of the cabinetry we build has faceframes, endpanels and counter tops that cover the outside of the box so its the inside of the cabinet that needs to be consistent. if you dado the top piece from the edge with the inside face towards the fence than the inconsistency will be on the outside of the cabinet where it will be covered by the countertop and endpanels.

this wont work for every application but with very little setup and 2 processes it produces a quick strong mechanical joint foe plywood boxes.

the amount of allowable tolerance for a plywood cabinet box (kitchen, bath, media unit etc.) is greater than for a furniture quality piece made from plywood. the plywood might have a noticeable size difference but for cabinet box construction it is an acceptable amount.

-

@titmas said:

domestic plywood is manufactured in standard dimensions, ie. 1/4" 1/2" 3/4"

imported plywood is manufactured in metric dimensions, ie. 5.2mm 12mm 18mm.

upon a closer look the measurements are not equal. 3/4" = 19.5mm

why is imported plywood thinner than its domestic counterpart?

domestic? as in domestic u.s.a? if so, your measurements are off.. buy a sheet of 3/4 here (u.s.) and it's even stamped 23/32 (though for simplicity sake i imagine, the price tag still says 3/4).. the domestics and imports are the same general thicknesses (nowhere near a 1.5mm difference)

@unknownuser said:

call it greed, call it efficiency, call it capitalism, call it whatever you want to but, all things being equal, the major difference between imported and domestic plywood is the quality and closely related to that is the price. it would be subjective to say that imported plywood is poor quality so to remain objective i'll just say that domestic plywood is produced with a smaller allowable tolerance where imported plywood has a bigger tolerance.

what?

imported plywood is way better(and the price reflects this).. use a few sheets of finland birch and that will become your standard to which all other ply will fail to meet..

[although you'll probably only be able to find it in hobby sizes right now in the u.s... i'm pretty sure i wiped out the entire u.s. stock of 6 & 9mm 8x4 sheets last year.. i really hope that's false so anyone please prove me wrong if you can.. ]for the more standard softwood plywoods, the only time i get 1/2" that's actually really close to 1/2" is when it comes from south america.. for cdx style plywood, this is the best stuff out there.. it always comes in 5-ply (as opposed to u.s.'s 4 or 3), less voids, stronger, and nearly equal in price.. note - u.s 3-ply 1/2" is even thinner than 4-ply.. that said, i always go with domestic 4ply 1/2" because of my application (i need to bend the stuff and the 5-ply is too strong)

@unknownuser said:

the easiest way to deal with imported metric plywood dimensions in your SU drawings is to use the metric dimensions that the plywood is manufactured with.

here are the sizes that metric plywood is produced in with the standard equivalent next to them.

metric- standard

2.6 mm - 1/8"

3.0 mm - 1/8"

5.2 mm - 1/4"

6.0 mm - 1/4"

9.0 mm - 3/8"

12.0 mm - 1/2"

15.0 mm - 5/8"

18.0 mm - 3/4"if that's how you like to do it, fine.. not really nice to pass this type of info along though...

Advertisement