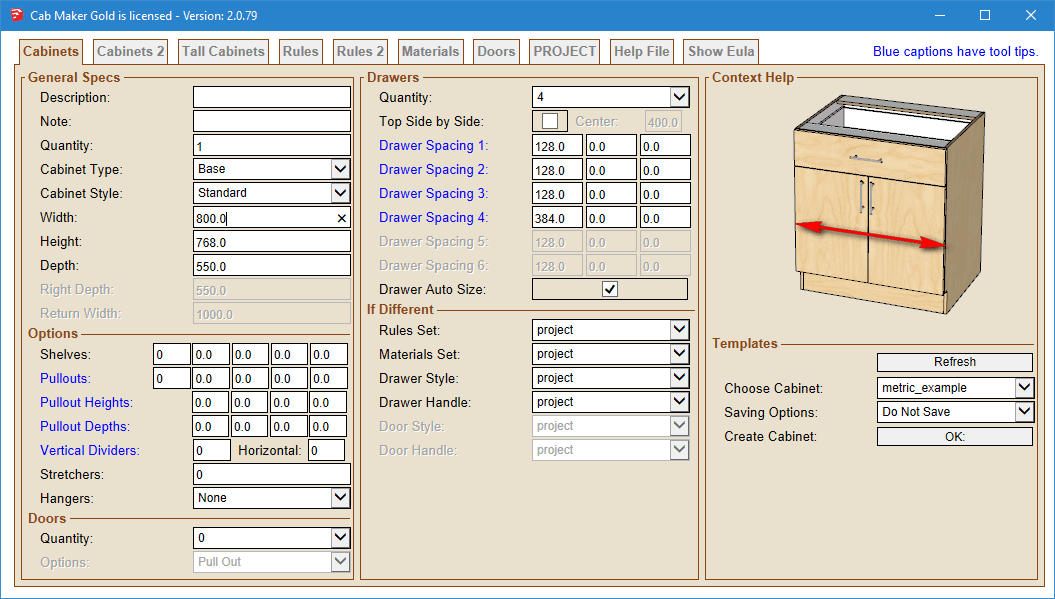

[Plugin] GKWare Cabinet Maker

-

CabMaker Version 2.0.79 is now available for download from my website

- Drawer Height overrides not working for Tall Cabinets. Fixed

- Added Drawer Depth overrides for 6 drawers.

- Added pullout Height overrides for 4 pullouts.

- Added pullout Depth overrides for 4 pullouts.

- Added shelf spacing override for 4th shelf.

CutMaster Version 2.0.1.44 is now available for download

- Added Blind dadoing for Backs where the back is the same thickness as the sides.

-

Version 2.0.80 of CabMaker 2 now available. Also CutMaster 2.0.1.45 is available.

CabMaker 2

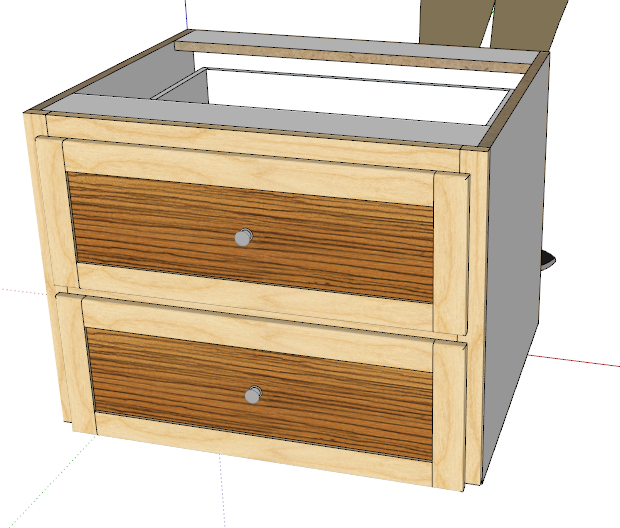

- You can now specify a different Top Drawer Style.

- Stretchers not position correctly for tall Frameless Overlay cabinets with drawers and stretchers. Fixed.

- Adjusted List_Parts_2 reports.

CutMaster

- Side Panels now only have hinge holes where necessary. So for a cabinet with 1 door hinged right would not have hinge holes on left side.

- DXF files for CNC can be created 1 per part for CNC operators with pod style CNC.

-

CabMaker 2.0.82 and CutMaster 2.0.1.47 are now available.

CabMaker

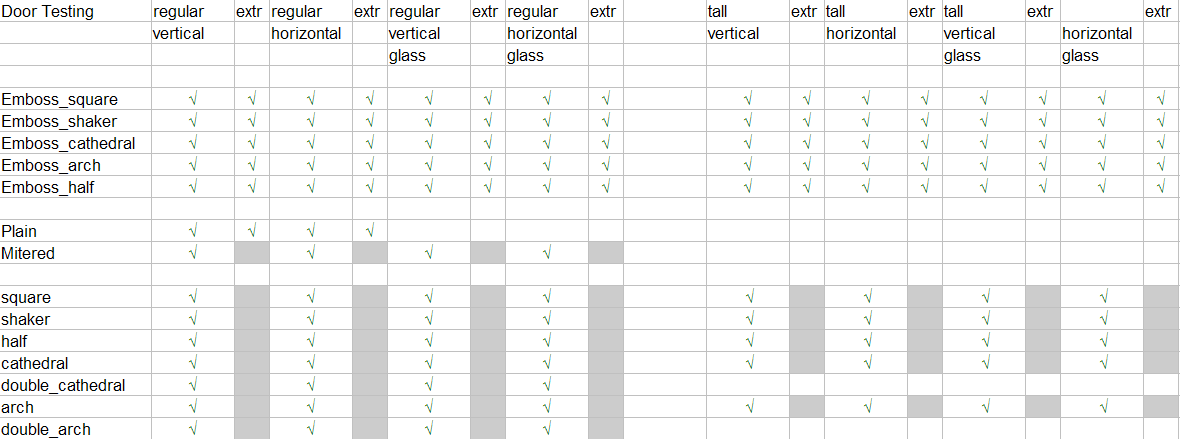

- Doors now have a horizontal grain option.

- Materials for skinned parts in the parts listing now have "_F1S" appended to the name.

- Sketchup followme has issues with certain Extruded handle profiles such as the new mondern one. Added an option to use Solid tools "Subtract" where Sketchup is Pro.

- Modified CabMaker DXF import to understand CutMasters new DXF options.

CutMaster

- Options now work properly with inches. Requires " mark

- Lists now can have last argument as c1 or c2 forcing CutMaster to divide the space by 2 or by 3

- Slides table in Database no longer restricted to 30 characters for holes.

- Options in red (mostly depths) can receive fractional inches.

- Added additional optional configuration for dxf files

- Added more layer names

- Added horizontal boring for dxf where 3D and where one part per dxf.

-

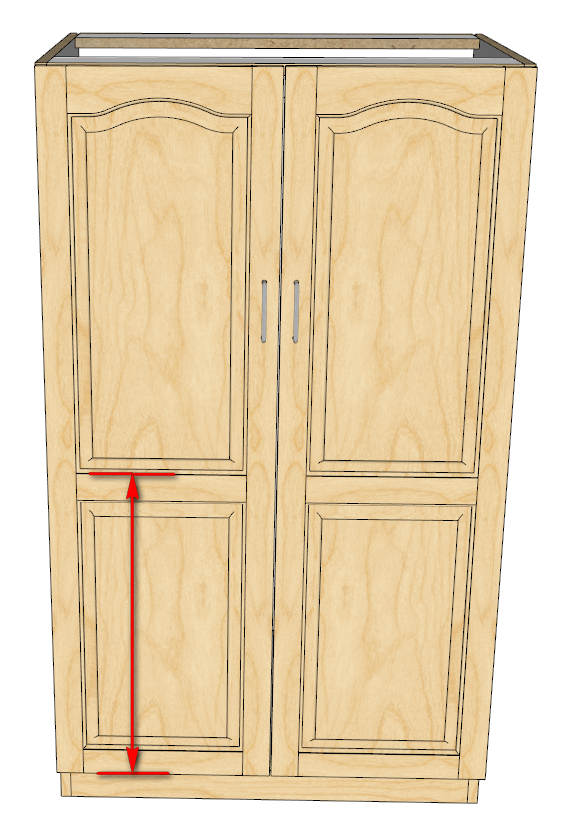

Adding the ability to adjust the height of the middle rail. This way you can have the middle rail for tall doors line up with your regular doors.

I'm also adding the ability to override the placement of and extruded handle. So you can set up a top drawer and have the handle at the bottom and have the handle for the rest of your drawers on the top.

-

CabMaker 2.0.83 is now available

- Tested all the door types and modified routines to complete the horizontal door options.

- Added door parameter so you can now set the mid rail height.

- Added override for extruded handle placement.

-

New version available

Version 2.0.84 – Jun 1, 2017

- Upper top edging wasn't working – fixed.

- Cabmaker was not honoring last drawer offset for some cabinet construction types –

fixed. - Panel material was not being honored – fixed.

- Editor was not showing the library template that produced the cabinet – fixed.

You can now create cabinets with a different inside panel

-

Awesome

-

CabMaker Version 2.0.85 is now available.

Version 2.0.85 – Jun 10, 2017

- Added main menu item “Edit Cabinet 2”. You can now create a shortcut for editing

cabinets. - Fixed some translation issues.

- Top and bottom eding for Finished Panels, Finished Backs, Blind Panels and Fillers

now working.

- Added main menu item “Edit Cabinet 2”. You can now create a shortcut for editing

-

CabMaker Version 2.0.86 is now available

- Added “Fixed Shelves”. You can now have up to 4 fixed shelves.

- Added pullout information and Drawer Depth information to the parts report.

CutMaster Version 2.0.1.49 is now available

- Added optional drilling for pullouts.

- Depth for Pullouts and Drawers are now used in determining slides and drilling pattern.

- Fixed Labels for Avery 06498 (1” X 2 5/8”)

-

Version 2.0.88 of CabMaker is now available.

- You now have a PROJECT rule for Base and a different one for Uppers.

- You now have a PROJECT setting for the insertion height for upper cabinets. You also

have a second insertion height if you hold down the ALT key while inserting a cabinet. - Added a renumber feature during a batch edit to PROJECT tab.

- Added a 'Template Defaults' section to PROJECT tab. There are 6 new parameters

where you can override cabinet heights and depths separately for Base, Upper and Tall

cabinets. - Added a Lock Section to PROJECT tab.

- Skinning Modifer couldn't be blank. Fixed.

- Now passing Adjustable Shelf information over to CutMaster.

Version 2.0.1.51 of CutMaster is now available

- Added Note Column to Parts Data.

- Parts Report now shows Note column.

- Import now has Note column and Shelf info.

- Added options for shelf supports. You set the center hole of the cluster from adjustable

shelf position in CabMaker. - You no longer have to restart after changing Edging thickness.

- Changed Match button on import to map several fields.

- Added more info to DXF file naming for 1 part per dxf.

- Fixed Third Hinge mounting bracket.

- Construction holes now honor edging thickness.

10.Added scoring option for Fixed shelves and Stretchers

-

CabMaker version 2.0.90 is now available

- Modified reports slightly to include Hanger information. Please edit existing cabinets to put into effect.

- You now have independent settings for Fixed Shelves, Adjustable Shelves and Pullouts for Top Section of Tall Cabinets.

- You now have pullout option for sink cabinets.

- You now have drawers in sink cabinet. Works well for cooktops.

- Fixed position of top hanger for base cabinets where the top is Front Stretcher.

- Text for “Saving Options:” now changes to “Locked:” when the lock is checked. Also the label and drop down is disabled when locked.

- You now have independent front and back dado parameters for drawer boxes and pullouts.

- You now have a double partition option for side by side drawers but not with a 3rd middle drawer. This can reduce the number of drawer box sizes. Also it creates a more symetrical drawer front.

- Added a bottom offset for upper cabinets (not fridge and not Tall).

CutMaster version 2.0.1.52 is now available.

- Added Bottom Offset and Hanger Width to Miscellaneous section in General DXF tab.

- Added Leg Levellers section and Hanging Brackets section to Connector's tab.

-

New CabMaker Version 2.0.91 – now available

- Added Model to Cabinets tab.

- Added drawer box back and front Offset. You can now adjust the vertical position of the

drawer box backs and fronts. - Modified reports slightly to include Model, Partition and Back Brace information.

- For Frameless construction you can now adjust Top Gap for Uppers and Base

Cabinets independently. - For Face Frame construction you can now override the Top Rail width.

- Fixed bug in Face Frame construction where the bottom rail is reduced and the cabinet

case extended below the frame. - Stretcher adjust behaved differently for various cabinets. Fixed.

New CutMaster Version 2.0.1.53 - now available

- Added a new tab under dxf configuration called Flags.

- Completed partitions (slide holes) and back brace (shelf supports).

- Double click on part (1 part per dxf) and associated CAD program will start up .

- Fixed stretcher adjust.

- Completed Hanger drilling.

- Added model to import (need to add column to mapping) .

-

Hi Garry,

Is some sort of cutlist functionality included with CabMaker 2 or do I need CutMaster 2 to make cutlists?

Do you have plans to make a Mac version of CutMaster?

-

CabMaker Gold includes several parts lists that you can make use of. Currently I am not considering redoing CutMaster for the Mac.

-

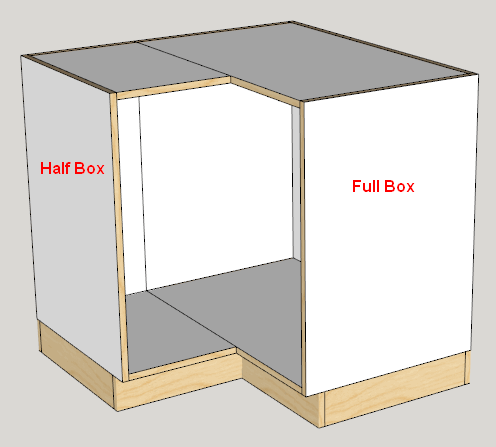

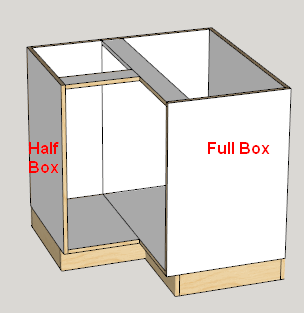

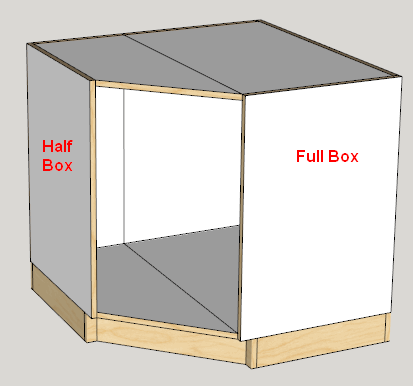

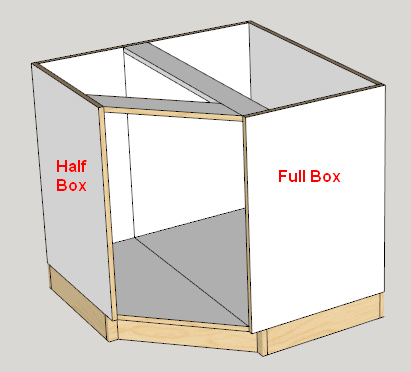

New work includes another way to handle corner cabinets. This separate box idea has many advantages including:

- Better use of materials

- Easier to handle in the shop

- Easier to transport to work site

- Easier to navigate boxes around corners and up stairs.

-

Great idea

-

CabMaker Version 2.0.92 is now available for download

- Auto Drawers now available with a single drawer.

- Added Omit Top Override.

- Added Omit Bottom Override.

- Added Omit Back Override.

- Reduce Hanger Width if too wide. Works good for desk drawer.

- Allow stretcher for partial face frame.

- Adjust Back height and positioning when omitting bottom or top.

- Adjust Hanger positioning when omitting bottom or top.

- Sending Top, Bottom and Back in reports to CutMaster.

10.Send flags slide in Back, Extend Back, Sink Stretcher, Integrated Kicks. - Added Extend Back Uppers.

12.Now Storing Last Number and Note with PROJECT.

13.Add omit Legs at the Cabinet level.

CutMaster Version 2.0.1.54 is now available for download

- Remembers last form size and position

- Report preview is no longer maximized. It is now centered and aprox 800 X 600

- Added modifier for Sides (Bottom=1, Top=2, Backs=4) These are added together

- Modified Joinery screen - added text box to Gap line

- Added NailerList for Dowels and Construction holes

- Adjust Side panel for 3 drawer sink cabinet

- Simplified General DXF screen. Removed parameters which now are sent over from

CabMaker.

-

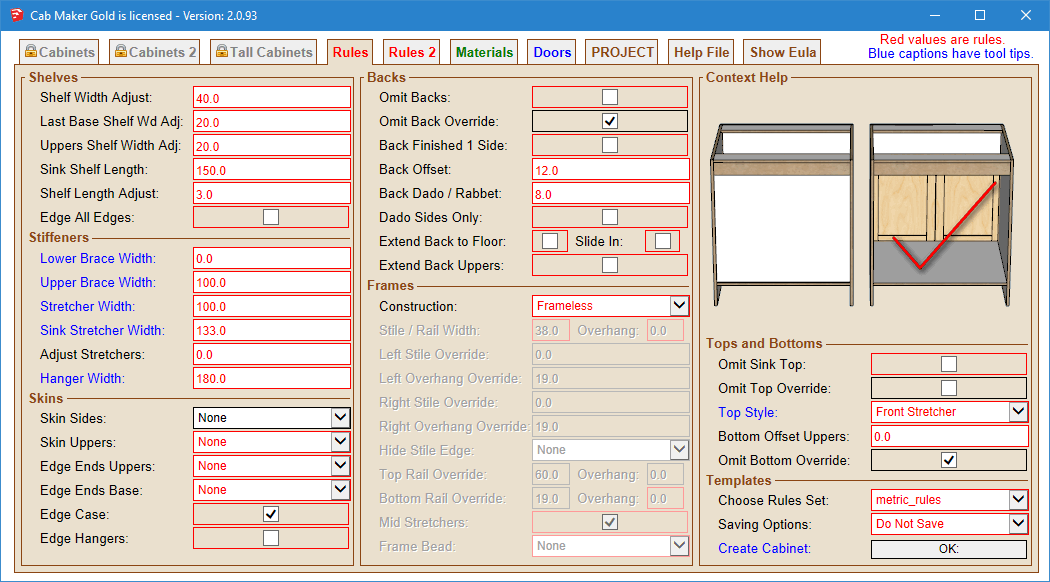

CabMaker Version 2.0.93 is now ready for download

- Tabs now have colored text. Black = Cabinets, Red = Rules, Green = Material and

Blue = Doors. - Tabs now display a lock graphic when templates are locked.

- Alt – L short cut now toggles the lock for the current Tab.

- Added a Search Filter for libraries.

- Tabs now have colored text. Black = Cabinets, Red = Rules, Green = Material and

-

oops - forgot to mention that The Create Button is now on all the tabs.

Here is the Rules Tab. Also notice the lock icon for Cabinets Templates.

-

CabMaker to CutMaster to CNC

Advertisement