[Plugin] GKWare Cabinet Maker

-

Version 1.0.44 fixes a number of bugs that where version specific

Ready for download - those running sketchup 2016 do not need to upgrade.

- Older versions of sketchup that used Ruby 1.8 and did not support round(decimals). fixed

- Older versions of sketchup 7, 8 and 2013 do not support adding linear dimensions programatically. CabMaker now detects sketchup version and only attempts dimensions for version 14.0 and greater

- The way I was grabbing images for cabinet templates only worked on recent versions of sketchup. Fixed

-

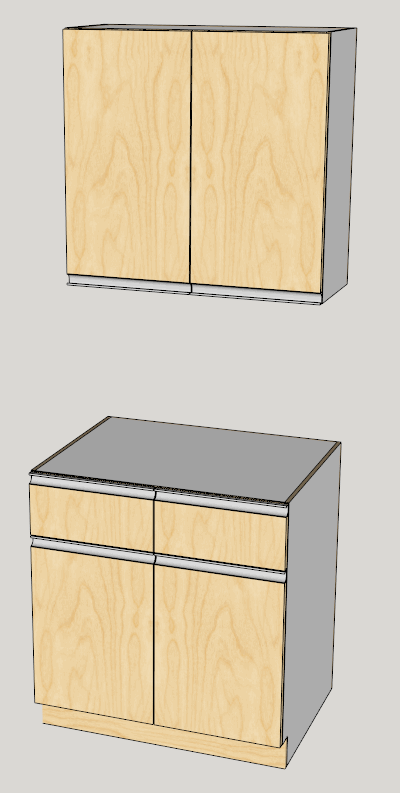

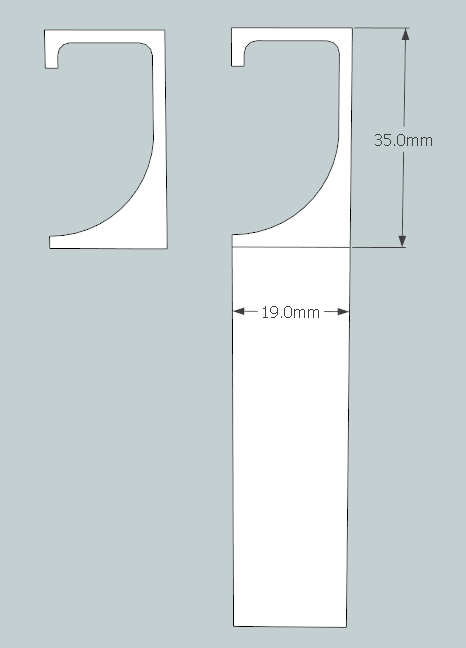

You can now create your own extruded profile and create plain doors or embossed doors with extruded handles.

Here is the profile that I've included.

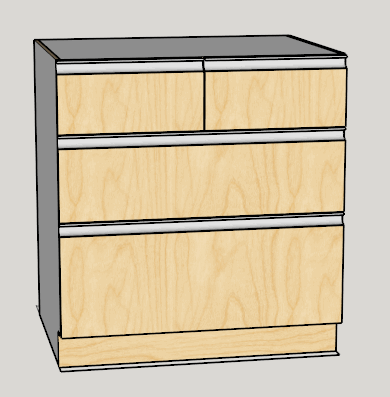

You can also create a top double drawer with a bank of drawers.

-

Awesome...!

-

Hi i have seen that some models use IKEA.

here is the IKEA Family-Color-Chart.

the base of the Colors is the PDF-File in the Archive.

This PDF was saved with " DIGITALFarbatlas"

the download for the Version5 is only avaiable in German.

-

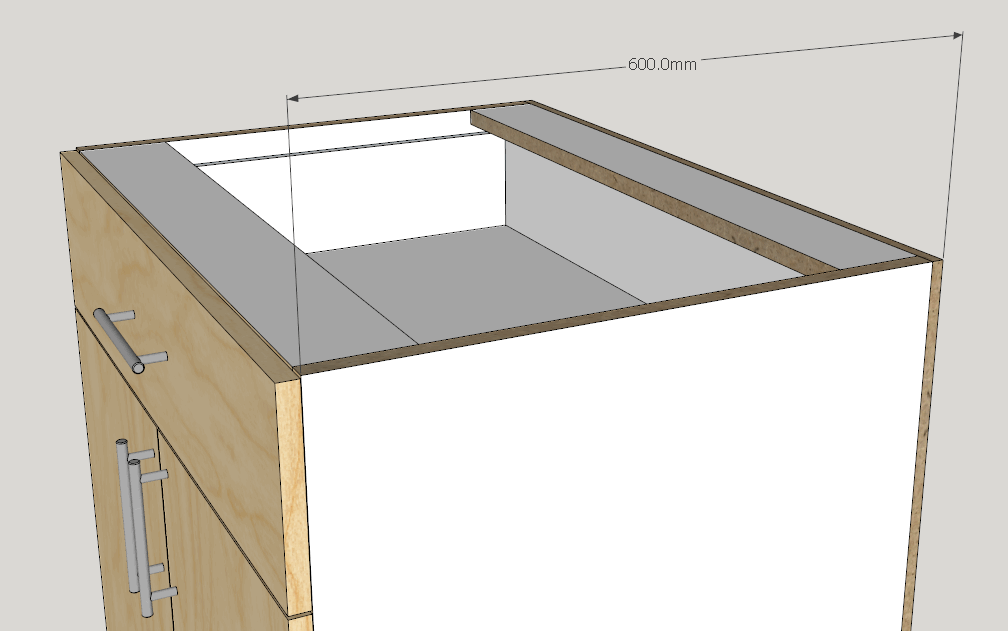

A user was asking how to have cabinets with plant on cabinet backs.

Simple. Set the "Back Offset" to 0 mm and set the "Back Dado / Rabbet" to the same value as the thickness of the case material.

In this case he uses a back thickness of 12 mm and a case thickness of 19 mm. His cabinet depth was set to 600 mm.

Also please note that the parts listing takes care of itself.

-

Version 1.0.45 now available for download.

Add a requested feature for face frame construction. You can now hide the left and or right outer edge of the stiles. This means you can set up your cabinets so that where 2 stiles meet they appear to be a single stile. This along with adjusting the width of the stiles will provide the effect of a single stile. Please note that you must have edge profiles turned off.

-

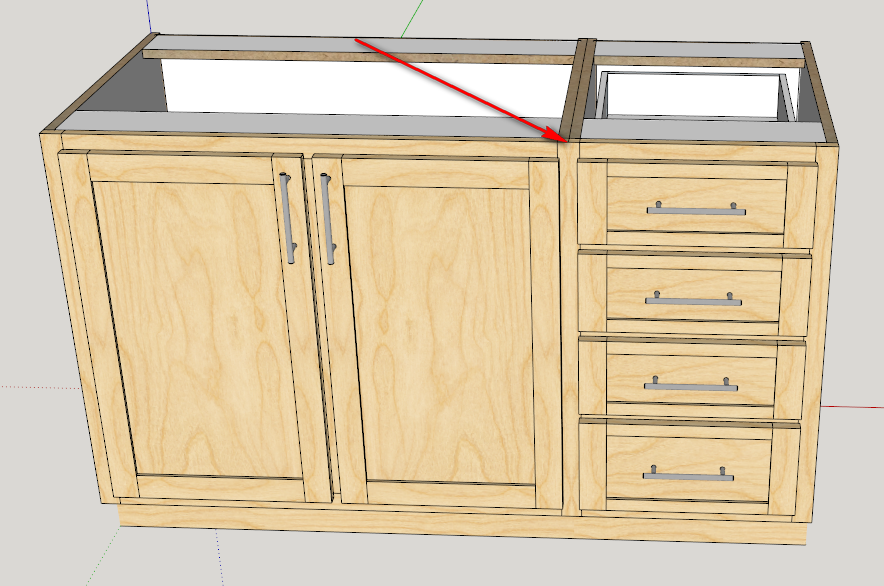

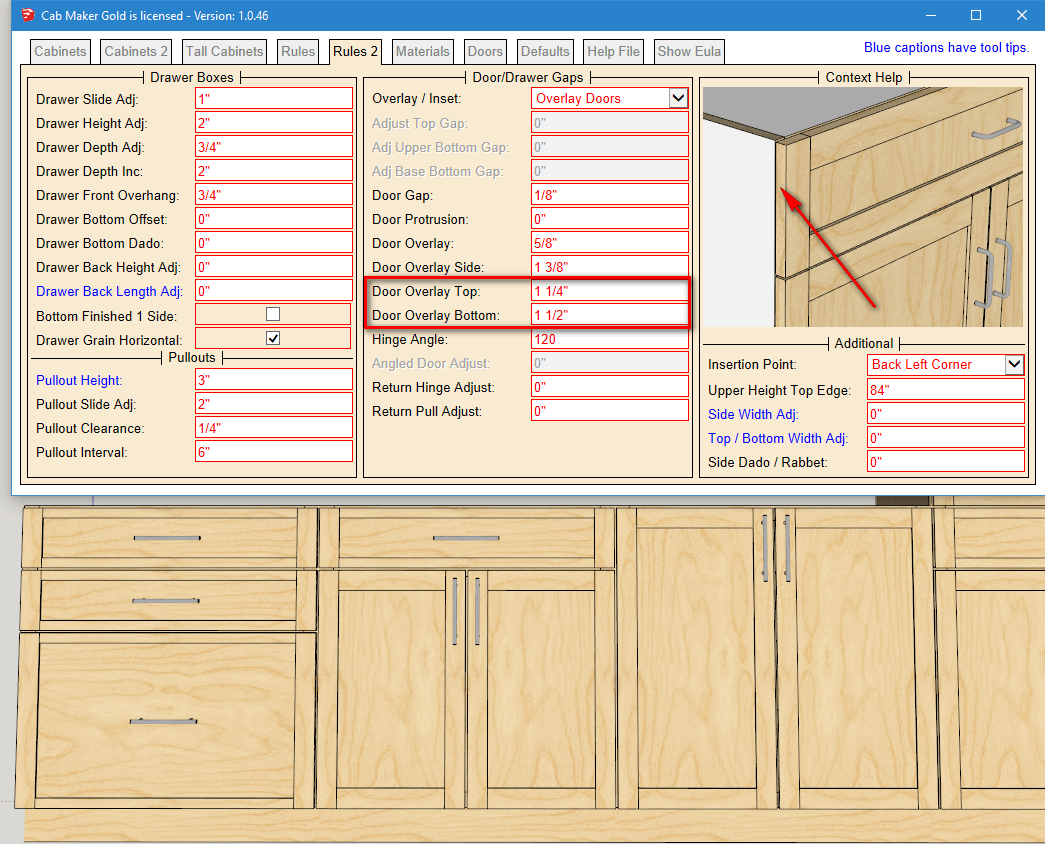

I've been requested for additional door overlay adjustments for face frame construction. Now you can adjust cabinets so that they have a similar look and feel to frame less cabinets but they have frames.

These cabinets have full face frames with 1 1/2" stiles and rails. Along with the 4 door overlay rules, this results in a consistent door gap of 1/4".

-

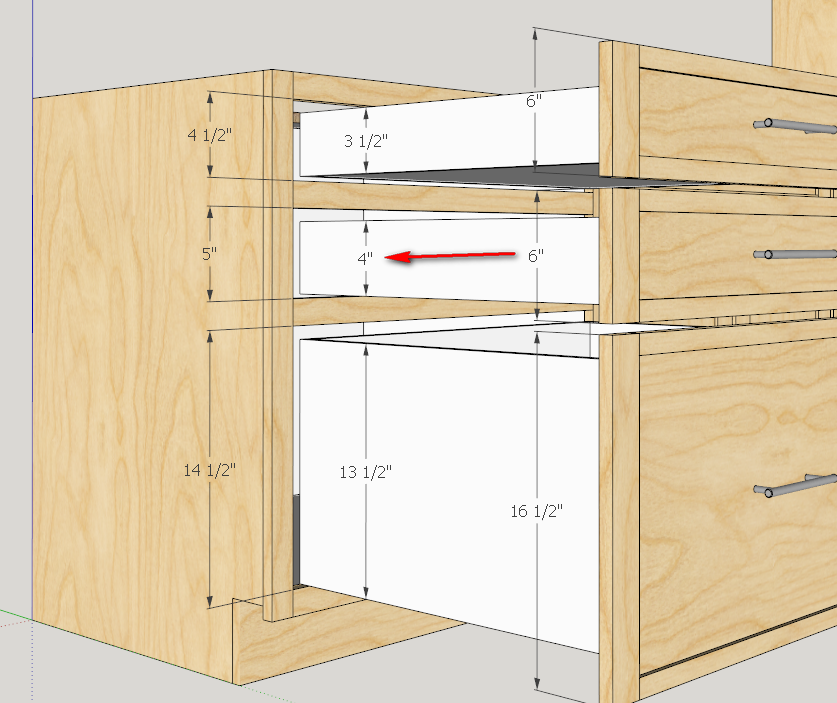

Just about ready to release. I have a question. Does this look reasonable for drawers and their drawer boxes or do you guys need something different.

I've got it all working but I'm not yet convinced that the drawer boxes are correct. For the 1-1/4" overlays I set the Drawer Height Adjustment to 2".

The 1-1/4" overlay has these settings.

Frame stile and rail width = 1-1/2"

Door Overlay = 1/2"

Overlay Side = "1-1/4"

Overlay Top = 1"

Overlay Bottom = 1-1/2"This works fine for the middle drawer where the drawer front ht is 1" greater than the opening.

However, the top drawer front ht is 1 1/2" greater than the opening.

And the bottom drawer front is 2" greater than the opening.What I have done so far is adjust the placement of the drawer box so that it has the same clearance at the bottom of each drawer. This part I think is right as it will better facilitate bottom mount drawer slides.

What I did is adjust the drawer box so that it maintains the same overall height clearance of 1". The other way to look at it is to try and use the same ht drawer box for the top 2 drawers and just adjust the bottom drawer.As we all know - the devil is in the details.

-

Version 1.0.46 is now ready for download

- Added Door Overlay Top and Door Overlay Bottom. This allows you to create cabinets with consistent gaps.

- Added Override Delimiter in Config file. This is for better compatibility with CabMaker and CutMaster Pro or CutList Plus.

-

Garry,

Any progress on the CutMaster Gold plugin? -

Sorry - I've been tied up on another custom project (got to make a living).

Hopefully I can get back to it early June.

-

Version 1.0.47 now ready for download. Fixed a few bugs.

-

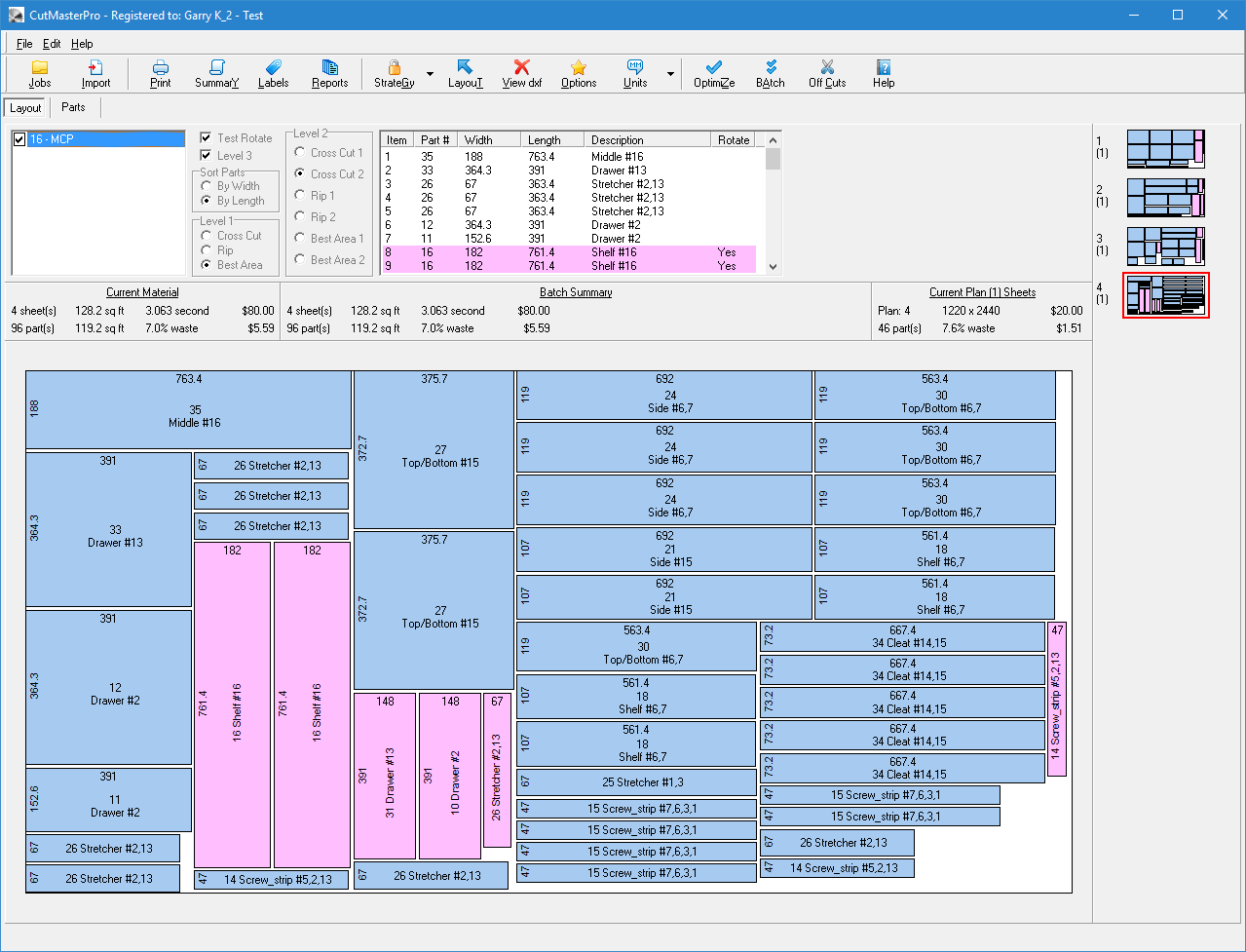

I have started working on CutMaster Pro.

Mac users will have to install Parrallels, Fusion or Boot Camp. The compiler that I use just has too many bugs for proper cross platform compilation. I am, however changing the way I store data to make it simpler and safer. Once the data base is changed I will then look at completing the nested dxf output.

-

-

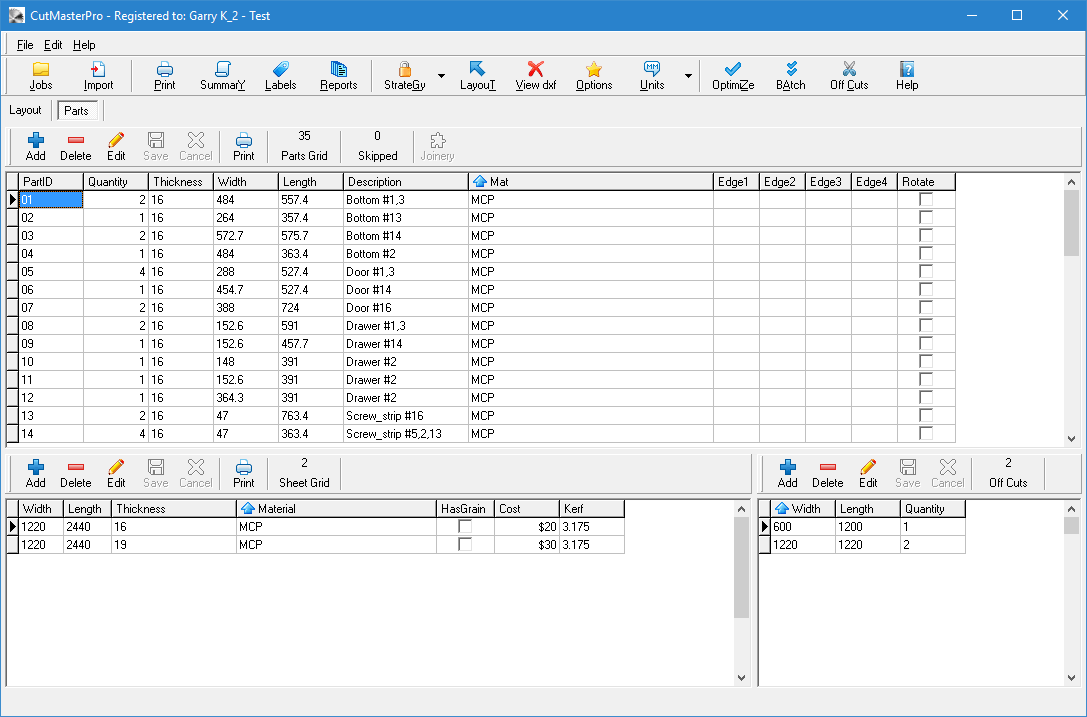

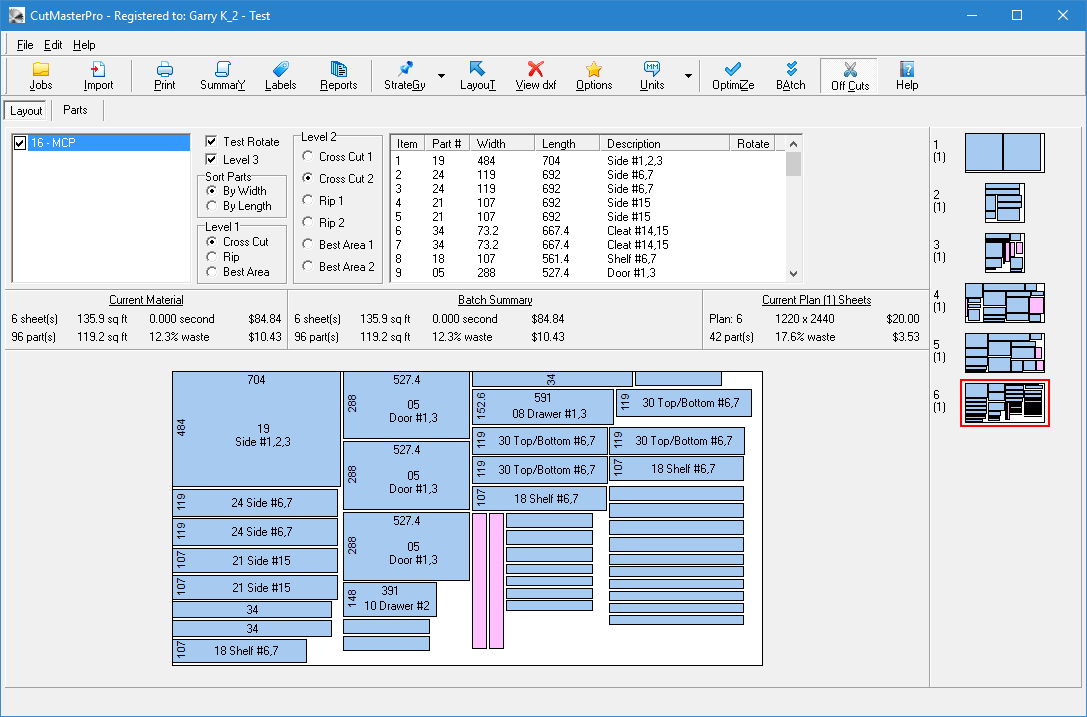

Here is CutMasterPro after importing a csv file. It is now using sqlite database where you can store many projects.

The right hand corner shows thumbnails of the sheets. In this case the 4th sheet is selected (red frame around the thumbnail) and the 4th sheet is also showing in the larger bottom area.

The pink represents rotated parts.

-

Very interesting !

-

Here is the same cutting list but in this case I've added 3 off cuts.

Notice there are 6 thumbnails. The first is the 600 X 1220 off cut and the next 2 are the 1220 X 1220 offcuts. They will be used first.

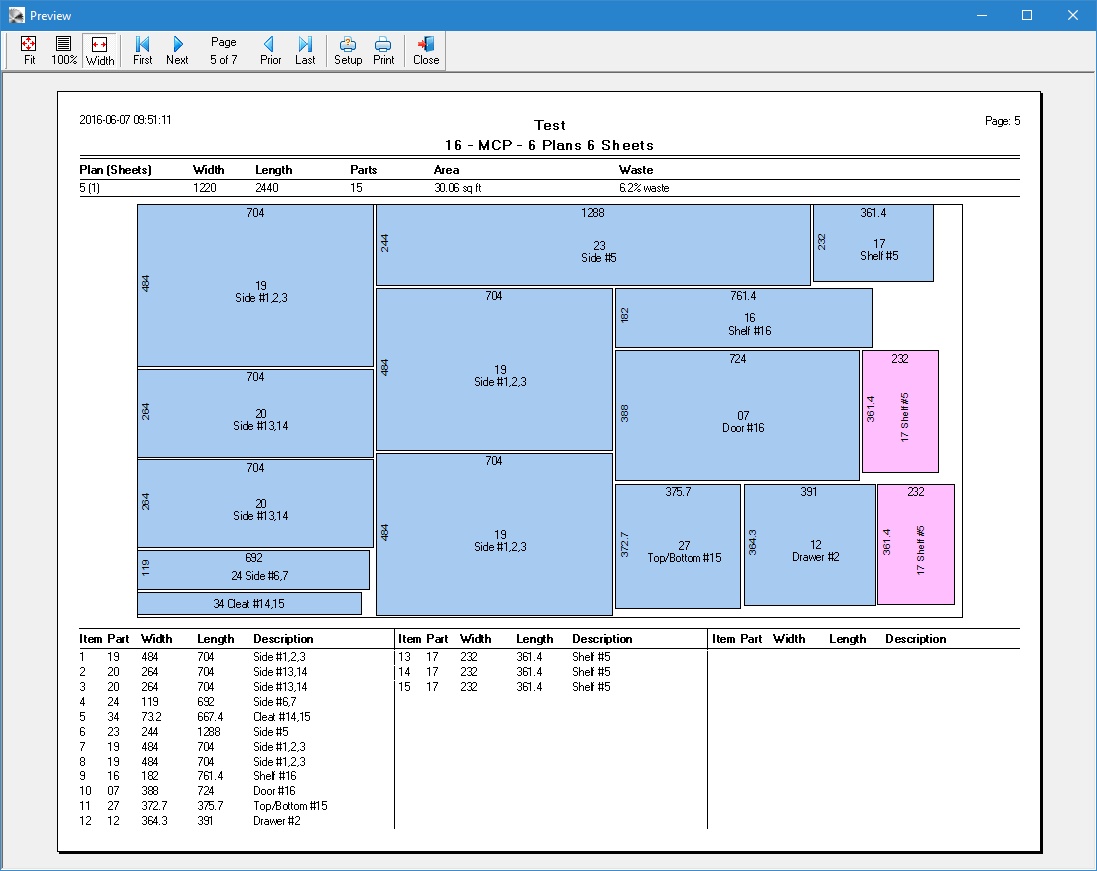

Here is 1 page of the cut plan report.

-

@garry k said:

...Mac users will have to install Parrallels, Fusion or Boot Camp.

Garry, you do realise that's a $300+ option to do do legally on a mac...

john

-

John,

That is unfortunate, but for me, reprogramming CutMaster for a Mac would around 3 months and that is not an option at this time.

-

I'm looking at adding edging information (along with additional information) for cabmaker's parts report. This information will be imported into CutMaster Gold.

So I'm thinking of adding edging on the Materials tab and also adding more rules for edging. Essentially each edge of a part can have a different edge.

This would then allow CabMaker to adjust the texture for edging.

CutMaster Gold would adjust the width and length of parts based on the edging and will show the different edges base on color coded lines on the cut plan reports.

Advertisement