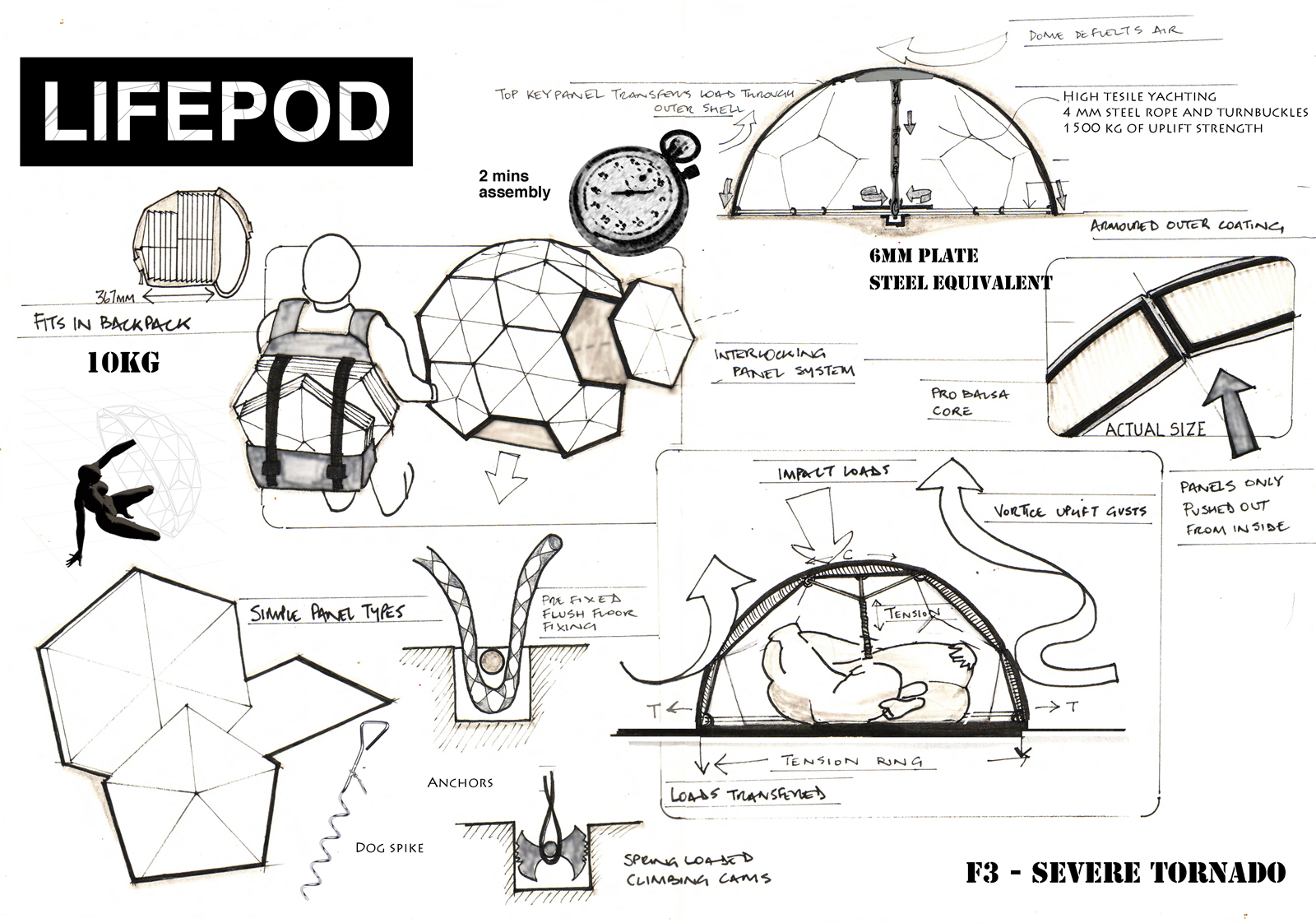

Lifepod Project

-

Hi, I thought I'd post this project as I do most of my development with SKP and podium, so go like up my lifepod !

-

Very cool.

-

Efficient!

-

This is the smallest in the range the T1 Tornado pod, it houses two adult with small children and is intended for short duration under an hour which is the case with Tornado's in America.

-

How long are you expecting folk to remain in that position? Two adults AND ? children? Looking at the posture I would not expect more than a few minutes in the case of one adult. It just looks too small. I think your expectations are too high.

-

@mike amos said:

How long are you expecting folk to remain in that position? Two adults AND ? children? Looking at the posture I would not expect more than a few minutes in the case of one adult. It just looks too small. I think your expectations are too high.

Hi Mike

This is the Tornado version that I have mocked up and tested to get the size of the panels, this is the bare minimum size and it's surprisingly roomy inside. The average pre warning phase for tonado's is 13mins with abatement within 30mins. The alternative's are not great and the majority of deaths and serious injuries are from flying glass - it's not supposed to take a car landing on it but it will give you a fighting chance up to a F4. It's made of Lexan in a range of thickness the 12mm one with 50mm flanges that create a flitch beam I'm looking forward to testing as it's going to be seriously strong. Have a look at the web site and thanks for your input.Also the plastic is distorting the people size in the render

-

Can't really evaluate the project itself, as I don't know this subject well enough, but what I have to say is that I have a great respect for you and your project. I hope that it'll work and change something for the better. That's the best use for tools such as Sketchup. Well done and keep it up!

-

Good luck with your development Stan. The 2012 UK weather has me asking similar questions regarding extreme weather survival; you may be on to something.

The biggest challenge will be selecting the right shell material for the four elemental extremes of wind, rain, heat & cold e.g. concrete may be good for high winds but it generally doesn't float unless well sealed and it doesn't offer much insulation for the "Day After Tomorrow" scenario.

-

@unrealviz said:

Can't really evaluate the project itself, as I don't know this subject well enough, but what I have to say is that I have a great respect for you and your project. I hope that it'll work and change something for the better. That's the best use for tools such as Sketchup. Well done and keep it up!

Thanks very much, gave me a real boost that

-

The original design, that I prototyped, was in FRP. I made a fibreglass balsa core and a kevlar panel, when I get chance to resize all the pics I'll update however, you can look at the prototyping here - please like it if your on facebook as I'm looking for funding

-

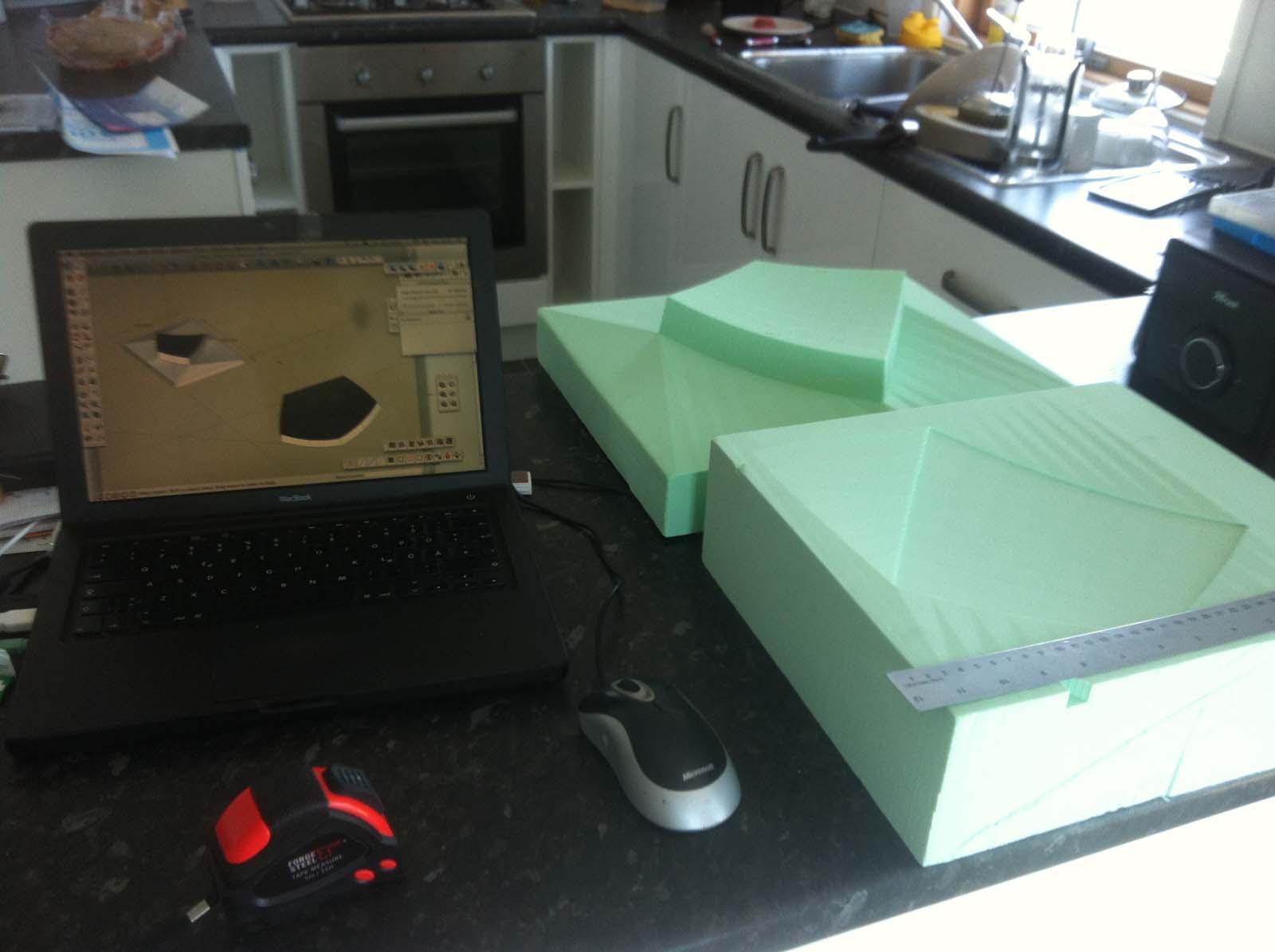

Some development photo's - The CNC machine wasn't big enough to cut a complete plug so the Hew was done in three parts and the Pentagon in 5, taking into account that every panel has an inner and outer shell and they take 12 hours to dry I realised I was in for a lot of work due to the CNC restrictions.

-

Finishing of the plug's and then to make the fully assembled mould. Decided to use Dioleen with expanded polyurethane core to test for Buoyancy and impact.

-

More and more interesting. How are you going to test it?

-

The first Hardboard design prototype was to actually get in it - designed in Sketchup with some poser models I could see it worked but until I had the dimensional model to play around with I wasn't completely confidant.

After the 2 part expanding Polyurethane GRP panels where made the fixing issue's became aparant and how the panels want to rotate on their axis under force, I had already realised sandwich construction wasn't going to work but cracked on to try and get a more complete prototype.

-

Stanley,

Your project is inspiring. It's nice to see physical reality from sketch's.

I'm working on a homeless shelter from a Trapezoidal Icositetrahedron shape and you have given me ideas about panel mateing. Bookmarking this page to follow. Are you on Google +? -

You guys should contact Architecture for Humanity - they might be interested in your ideas and projects.

-

@dadio61 said:

Stanley,

Your project is inspiring. It's nice to see physical reality from sketch's.

I'm working on a homeless shelter from a Trapezoidal Icositetrahedron shape and you have given me ideas about panel mateing. Bookmarking this page to follow. Are you on Google +?Thanks -

I had a kind of homeless igloo idea for my home town that attracts lots of homeless people. The construction was hot wire cut polysterene 100mm thick in panels with an external laminate of GRP. I've been working on this for 2 years solid. -

This is the probalsa core with a Epoxy kevlar in a sandwich construction

-

Log into Facebook

Log into Facebook to start sharing and connecting with your friends, family, and people you know.

Facebook (www.facebook.com)

Lifepod Project

Following my research and design into disaster shelters, I have come to the conclusion that a community level solution is required, built from simple materials, cheap and easy to build.

The Lifepod Project manifesto -

Community self build disaster shelter

Made from one pentagon and one Hexagon mould in reinforced concrete, it's strength and shape make it extremely strong and cheap to build above or below ground. It can be watertight and ballistic proof. It is built off one simple pile foundation and can be unbolted internally in the event of extreme flooding, a shelter for natural disasters built in the center of communities - schools or college's -

Will be very useful after the actual tragedy of the Philippines!

Advertisement