My first woodworking project

-

I made most of the edging 6mm thick. that would be similar to the typical 1/4-in-thick edging that would be common here. It would be soild wood glued onto the edges of the plywood. It is more durable than that thin glue on edge banding and I think it looks much nicer. You can use a matching wood or a contrasting one. Some of the edging is thicker but in most cases it's all the same.

If you wrapped a steel band around the cams (the sides of the pivoting part) and put rare earth magnets in the hinged front panel so they contact the band, the panel would follow the cams as the top rotates and yet you could pull the panel open for access.

As to the axis thing, yes, mainly I corrected the axes to make applying materials with proper alignment at least more predictable.

I'll be interested to see what you come up with.

-

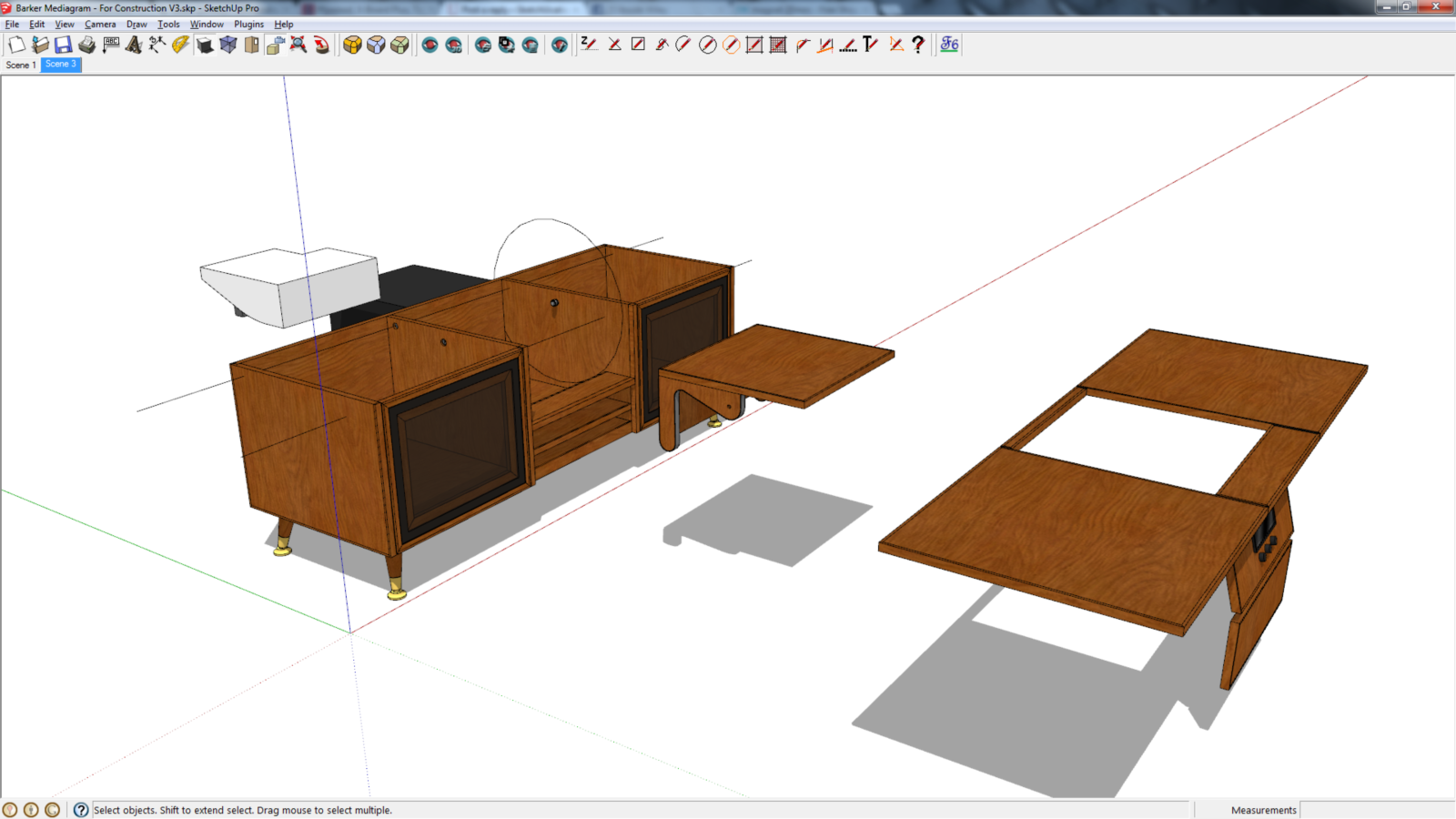

Added some more edging. Re-worked the rotation with magnets for holding the front panel to the cam. Added skate bearings for the rotation (not sure that this is the best method, but I had to try something). Added locating magnets for the rotation open and closed.

I also did a little work on the doors but I'm not all that happy with it. I'm not sure what I want it to look like to be honest.

Barker Mediagram - For Construction V3.skp

-

At least you can work it out in SU before committing to wood.

Do the side piece on the center section have to be shaped as you have them?

-

With next to no woodworking experience, Sketchup allows me play around with concepts and design variations at no cost but time. I'm not sure how you all coped before 3D modelling.

The side pieces don't have to be exactly like I have them but I do want them to be rounded for a gentler contact with the front panel (the circle in my model is the path of the rounded side). I guess the sides could be made up of 2 pieces, one for the pivot and another for the cam. The thin board between the cams is to hide the projector a bit and has to have a clearance gap for cables to pass through. I have some more ideas for this that I will work on a bit over the weekend (it's late Friday night here). This has been a very interesting and enlightening week.

-

Things have been a little hectic, so not a whole lot of progress. Here is an updated, yet still in progress 'for construction' model. I have altered a few things, removed the false bottom below the projector, added speakers (thanks to CaljuCotcas on 3D Warehouse for already drawing them) and some airflow management for the HTPC rear fans. I still need to think about airflow for the projector and more cabling holes.

I'm not all that happy with my method of supporting the front panel when it is in its closed position. All I have is two small triangular stops, but I am struggling to come up with a better method that isn't in the way of the projector rotation.

I will keep plodding along and continue to update as I go.

Advertisement