Creating a vacuforming die

-

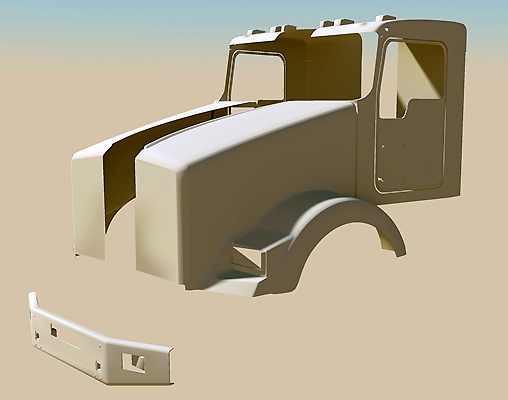

I am helping a guy who makes presentation models of trucks to create a vacuforming die. There was a good model in the warehouse, but I had to strip it down and toss all the parts that he will bescratch built. Then I split the model into halves so the draw will not be too deep, also need to facilitate removing the male die from the final plastic shell. Next step is to build a base that flares out so there will be no undercuts to trap the die. Once the virtual model is finished we will send it to a rapid prototyper to 3D print the die.

-

Neat project, Roger. I hope you'll keep us posted on the progress.

Neat project, Roger. I hope you'll keep us posted on the progress.Do you know yet what 3D print service and print material you'll use?

-

Will keep every one posted. Have not selected a 3D print service any suggestions? Any thoughts on how to differentiate services other than price?

-

I just had my first 3D print made recently...I chose Shapeways because they had the best price, an option to return within 10 days if there is a problem with the printed model (I had no problem, but I like the guarantee), and the fact they have an active forum if I need help with anything.

I guess material selection between print services would make a difference. Most of them offer nylon/polyamide (Shapeways calls it White, Strong and Flexible), which is the most popular because of its high strength and low price, but you may need a different material for your needs. If you do need a material with higher detail/smoother surface than polyamide, Shapeways is trying a new material for the next 8 weeks, see details here: http://www.shapeways.com/blog/archives/812-Introducing-3D-Printing-of-new-smooth,-ultra-detailed-material.html

-

Could you post a photo? And if it is not sensitive tell me what it cost?

-

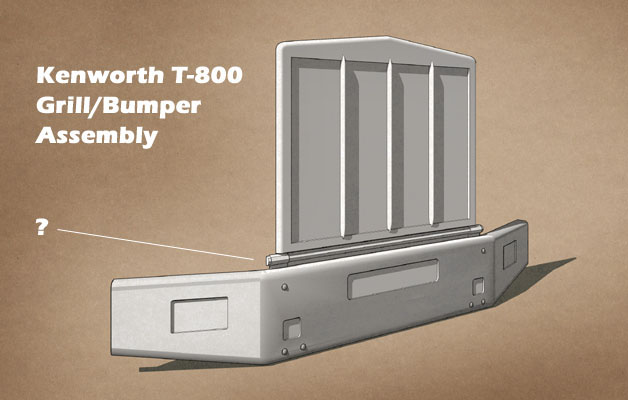

This is the grill/bumper assembly. I have to go back and find the company crest and am suggesting we don't do the cab hinge as an integral part of the vacuform model, but add that detail with a piece of piano wire with a little brass sleeve on the ends.

This is a 1/32 scale model. Any ideas for something that could be cut and inserted into the grill spaces to simulate radiator vanes?

-

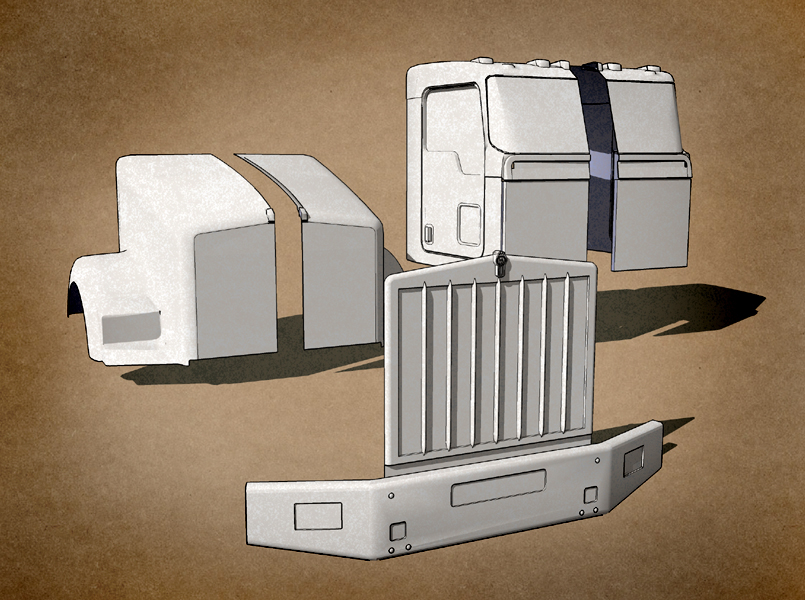

Here all parts are assembled to make sure everything will fit

And here the parts have been exploded to begin the creation of male dies for vacuforming.

Next I have to seal up open cavities and run a routine to make sure the parts are airtight before sending the files to the 3D printer.

-

Looking good, Roger

-

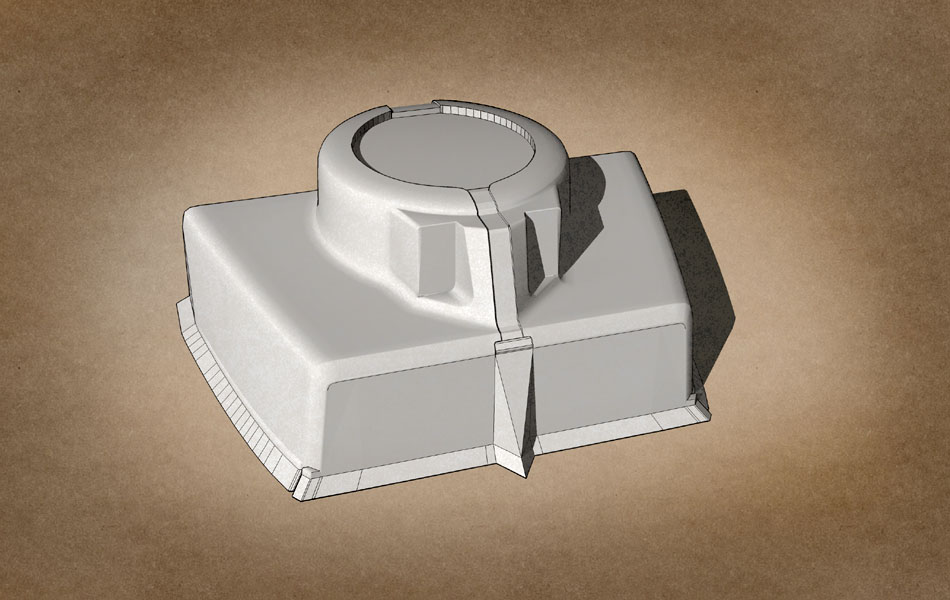

This is what the draw from the fender and hood die should look like when removed from the vacuforming process. This is the right and left units before being cut apart. The flares at the bottom are to guide the model makers knife and grinding tools. Any bets on how well this will work?

This is what the draw from the fender and hood die should look like when removed from the vacuforming process. This is the right and left units before being cut apart. The flares at the bottom are to guide the model makers knife and grinding tools. Any bets on how well this will work?

Advertisement