Adjustable desk feet

-

I'll wait to see your model. Relative to the cost of the lumber for the desk, tee-nuts or even the coupling nuts would be pretty cheap. One thing I would think about is if you have to extend the legs much, the lateral loads on the feet could be somewhat substantial. Tee-nuts are short and a bolt or the threaded foot will fit loosely inside. It won't take much to loosen them in the legs. You might drill the holes slightly under the diameter of the threaded part of the foot. Counterbore only deep enough to insert the tee-nut. Insert the tee-nut and thread in the foot or a bolt with the same thread pitch and cut threads in the wood. Unless the wood is hard like maple, the threads won't be great but they'll help and they'll prevent the feet from being wobbly.

-

Oh I wouldn't think of using tee nuts for anything as substantial as legs. I'm sure it can be done but would involve more work than its worth. I like to save some money but I also like things to be done "right" (depending on who's definition you go with) but mostly I like things to last.

Just so you guys know, the right "wing" of the desk won't simply be supported by a single piece of 3/4. Im building in a 3-4 inch wide cabinet for my extra keyboards and wires and stuff. And yes I realize the three-legged approach with the center section is prone to tipping forward if it were on its own.

-

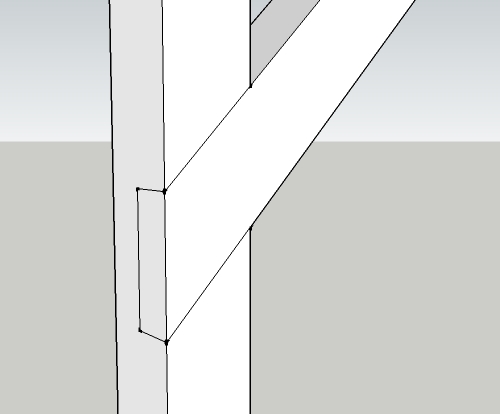

Is the notch in the rear leg to allow cables to pass through from the monitors? If you plan to build this in sections, you might add some legs to the center one on either side of the "knee hole" so it'll stand up on its own.

Crossing posts.

So what are you going to use tee-nuts for? I thought you were talking about using them for adjustable feet.

-

@dave r said:

Is the notch in the rear leg to allow cables to pass through from the monitors? If you plan to build this in sections, you might add some legs to the center one on either side of the "knee hole" so it'll stand up on its own.

Yeah thats what the notch is for.

I need to work on that considerably. I don't like the way that post is currently at all. Open for suggestions. The way it is now, there is nothing stopping it from just falling forward, short of throwing a couple bolts into it.

As for the t-nuts, it was just an example about prices of things in bulk compared to going to the hardware store. I'll really just be using them in the construction of the monitor stand. The "swivels" are so over-designed I don't think they will have any trouble holding the weight of a single monitor.

-

Have you ever used McMaster-Carr? There are packages of 12 for as little as $3.50: http://www.mcmaster.com/#adjustable-feet/=bqads0.

-

@ledisnomad said:

Have you ever used McMaster-Carr? There are packages of 12 for as little as $3.50: http://www.mcmaster.com/#adjustable-feet/=bqads0.

Thumbs up for awesome.

-

Glad I could help!

-

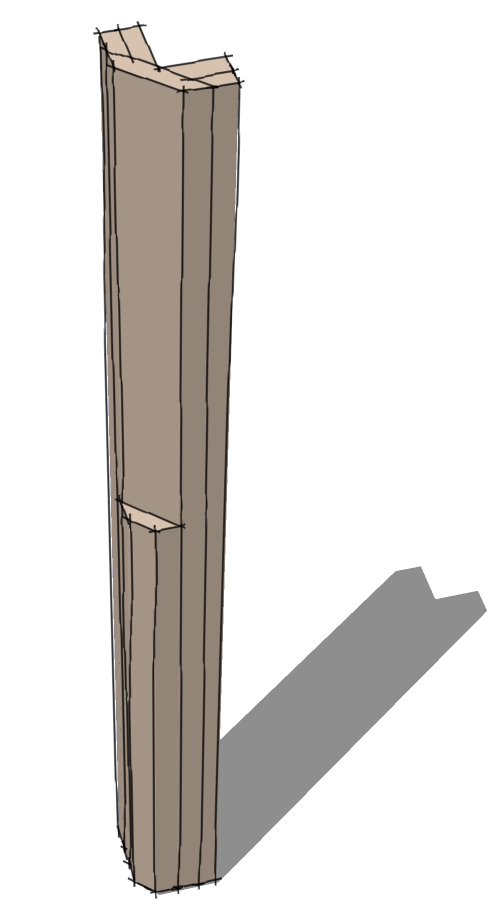

The texture is a bit off in some places, but I think I have a suitable method for attaching that post now.

Sorry about the big file size. I think its the .gif I have on the screens xD

-

I like the change you've made to the back corner and to the right side. I think you could mange without the channel cut in the back of that leg, though. Instead of joining the diagonal braces to the legs as you've shown, you could get more strength with lap joints.

-

@dave r said:

I like the change you've made to the back corner and to the right side. I think you could mange without the channel cut in the back of that leg, though. Instead of joining the diagonal braces to the legs as you've shown, you could get more strength with lap joints.

You mean like this?

Thats doable. Didn't even think about that, I was wondering how I could do that better. I can certainly make that cut, but whats the best way to do it? Running it across the table saw a dozen times is one way, but I also have a mortise attachment for the drill press that would make that easy. I could even run the diagonal piece right THROUGH the center of the leg if I go that route. Forget the name of that joint...Would just have to pound together a small jig to hold it, hell, I might even have one already.

The channel cut into the back of the post is so I can staple in some of those plastic ties to hold power/monitor cables. If anything I'd like it to be a bit larger, but I don't like to have structural things break on me. The only reason it runs all the way to the floor is because it might be simpler just to make the cut down the entire length rather than try and only do part of it.

In case you are wondering how I have all these tools and only half a brain to put them to use, its because my grandfather (who recently passed away) had a very large collection of woodworking tools. It has since been passed on to myself and my cousin, who likes to carve. I know how to USE pretty much every basic tool you can name, and a few of the more specialized things like kreg jigs, mortise attachments, stuff like that.

So the functional experience is there to be able to do a lot of stuff, but only now do I have sufficient space (to put it) and money to buy materials. Designing things is another story, so I do greatly appreciate suggestions.

-

That's what I had in mind. There's probably some sort of dado set in your grandfather's shop. It's a stack of blades to go on the table saw. You'll have to make several passes with it to get the width--max for the dado set is usually 3/4". You could do a mortise and tenon joint but it would be a little more of a challenge to get right. Not much but a little.

I think I would still forgo the channel on the back and make it flat. That's easier and you'll still have room for cable tie holders. You'll have more room at the bottom for the foot hardware.

Remember, count 'em when you go in and again when you come out. The number is supposed to be the same.

-

@dave r said:

That's what I had in mind. There's probably some sort of dado set in your grandfather's shop. It's a stack of blades to go on the table saw. You'll have to make several passes with it to get the width--max for the dado set is usually 3/4". You could do a mortise and tenon joint but it would be a little more of a challenge to get right. Not much but a little.

I think I would still forgo the channel on the back and make it flat. That's easier and you'll still have room for cable tie holders. You'll have more room at the bottom for the foot hardware.

Remember, count 'em when you go in and again when you come out. The number is supposed to be the same.

Im about 80% sure he never had a set of dado blades, otherwise I will just use those. Much easier than trying to hold the board at some odd angle on a drill press. I'll probably just use the table saw to make them, when the time comes.As for the channel, the idea is to be able to hide all the cables entirely. If I made it flat they would still be visible from either side. Cutting the channel is much easier than trying to cut it at an angle. Two passes over the saw and its done. but once I have the back cut, that front face will be easier.

Cutting the flat front on that post will be harder by far. It doesn't go all the way down. As for there being room on the bottom of the foot, the area at the bottom is essentially three 2x2 squares in an L shape. The foot has more wood to go into on the post than any other ones.

I don't want to sound like I am arguing your point though! I do see what you are saying.

-

So what tools are actually in the shop?

-

All kinds of stuff. Basically every hand tool you would ever need. Planer, jointer, scroll saw, drill press, table saw, compound miter saw, a combination oscillating spindle/disc sander, grinding wheel, buffing wheel, lathe, bandsaw.

All manner of hand power tools: drills, palm sanders, TONS of Dremels (of various models, he was on the ideas board or whatever its called for Dremel here in Racine)... Not sure I can even come close to naming all the tools available to me.

I don't think there is any basic type of woodworking project that cannot be completed in his shop. Certain very particular techniques requiring a very specific tool might be out of reach though, but I think I can live with that.

And most important:

Dozens and dozens of clamps of varying sizes and types.

-

Shoot! You're practically my neighbor. Well, not really. I was near Madison on the weekend though.

I'm still on that back leg although I'm curious about the rest now, too. You've drawn the leg as basically 4" square. What are you planning to use for lumber? Are you planning to buy a 4x4 at Menard's or something? Or will you be building up the leg out of multiple pieces or milling your own from rough stock. If you are planning to use a 4x4 from the DIY store, you'll want to revise your plans because a 4x4 is about 3-1/2" on a side. Your 2x2's will be closer to 1-1/2" on a side.

If you are very careful, you could tilt the blade on the table saw and cut the bevel on the upper part of that rear leg. You can finish it with a handsaw and hand planes. Maybe a bit of card scraper action at the end to make the surface nice as smooth.

Also be very careful when cutting the notch out of the back of the leg. the first cuts no problem but the second cut could be. Don't let the wood tilt into the blade.

I'd be inclined to build that leg as a box out of 3/4" thick stuff. You'd get a lot of strength and waste less wood.

-

Yeah, I was actually out in LaCrosse and Onalaska not too long ago doing a stop for work. I'm clear across an entire state from you but, close enough.

Anyways, I've made cuts like that before. Yes, there are safety concerns. But... A TRICK!

After making the first cut, tap a small piece of thin scrap across the cut using a couple small finish nails or a staple (cut the piece a bit longer than the final length if you are worried about the holes) on either end. As long as it holds, you don't have to worry about launching a strip of wood into yourself or the wall behind you.

It will also prevent the piece from tipping down into the blade. Takes a couple seconds and just about ensures you won't mess up the cut or kill yourself with a piece of kickback turned bullet. Something I learned in highschool after making a cut like this and doing exactly what you described on the first attempt.

As for the stock, I was actually thinking about gluing up 3/4 and planing it to a 4" square. I am well aware of stock being less than its "intended" dimensions. I would probably do the same to make the 2" pieces. Not sure what I will be making the whole thing out of, but oak is likely since I am familiar with the stuff.

I will probably see if I can find a lumberyard that carries rough stock at true dimensions. One of the first things I learned was how to process 5/4 stock into basically anything. Including 48x30" sheets.

-

I just don't want to read about you in the paper.

How about building it up this way?

Go over to Kettle Moraine Hardwoods. If nothing else, you can drool on the selection. They ought to have a good selection of oak, though.

If you were in LaCrosse, you were almost here. How come you didn't come to visit?

-

Lots of extra cuts that way. Then you would have to cut each piece slightly over-sized (4 pieces at ~3 cuts each), glue it all up, hand plane the joints smooth. Gluing alone is a hassle with the odd shape.

Much more work than gluing up 4 pieces of 1 1/16"x 4 1/4" then planing it to 4" square, making 4 cuts and some minor hand finishing.

Plus it wouldn't be quite as strong as a solid piece.

-

Actually, it would be stronger than one piece. Yes, it would be more cutting. Gluing wouldn't be difficult though.

I'm looking forward to pictures of your desk.

-

Advertisement