Can you make holes as separate components?

-

I am trying to make multiple holes in a component using different "cut-through" objects as the holes without disrupting the component itself. The ones I make only work if the surface I'm "drilling through" is not already a component. To put the pre-made hole into a preexisting component I have to edit the component itself and copy/paste the hole into the component, which then changes every other iteration of that component. I want to avoid making the other components unique. Is there a way to do this?

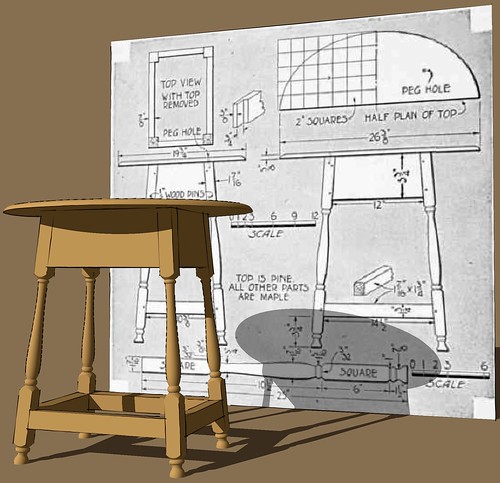

As a practical explanation, say I was designing an end table like the one in the picture. It has 4 legs that are identical (or mirrored) when milled up, but the mortises for the joinery in the front legs are different than those in the back. I would typically make one leg, duplicate and flip it 3 times to make 4 legs, each mirrored appropriately, then make the back two "unique" so I could mortise for side and back aprons in one back leg, and for side aprons only in a front leg. The respective mortises would then be transcribed from the left leg to the right leg on the correct face.

Now let's say I want to resize or add a taper to the legs. As created above, I would have create the taper twice - one front and one back. Not too difficult with 4 legs, but for resizing an entertainment center that has 12 panels, each with different holes or dadoes would take forever. What I want is to have sketchup treat the joinery separately, so all of the "same" parts could still be multiple iterations of the same component and adjustments to the design would only need to be done once.

Has anyone done this?

(Image borrowed without permission from this site and is to serve as example only. I claim no ownership of the photo or the design of the table in the photo.)

-

Hi Brad,

No, I am afraid what you want is not possible. A component can only be manipulated "from inside" and even other components that can cut holes work only on bare faces and not through component "skins" (I just made this up).

You could still place these holes onto the surfaces of the components and only make them parts of them when you are done with the whole design.

@rbbauer said:

(Image borrowed without permission from this site and is to serve as example only. I claim no ownership of the photo or the design of the table in the photo.)

Hehe... I was already going to add "nice table and render" when I saw the small prints.

-

I was afraid of that. If there are any Sketchup developers out there, this would make a great plugin or, better yet, version upgrade!

Oh, and thanks for the would-be complement, but unfortunately I have no idea how to do photo-realistic rendering.

-

I draw furniture of this sort all the time and I understand what you are getting at. As Csaba says, you can't do what you are asking as nice an idea as it is. I tend to leave the Make Unique process for as late in the design process as I can so as to avoid as much duplication of effort as possible. I try to think about how I would make the pieces in the shop mentally grouping operations to avoid having to set up a machine again. You might consider waiting on the joinery until after you've settled on details like the taper of the legs and width of aprons, etc.

Another option--although it has its pitfalls--is to split the leg into sections. For example, in this table model I drew the leg as four components, the foot, the square section at the stretchers, the turned part above the stretchers and the top above the pommel.

This is the same table. The only difference is that I swapped the turned section with the barley twist section. Very easy to do once everything is set up.

The downside is that unless I exploded the lowest level component in the leg component, the cut list will incorrectly report the leg parts. If you don't care about the cut list, though, it's not a big deal. -

Dave,

That is a good solution to the problem which has indeed bugged me from time to time. Can't think why it didn't occur to me!

Advertisement