Cabinet Design program for Sketchup

-

Hi Bob, I did take a look at the tomatoes plugin last year and took another look this morning to see if the concept was still the same - which it appears to be. It lets you easily create cabinets, but lacks the ability to modify the dimensions or contents afterwards - that's a task that you do on your own or through another tool like FredoScale. I think that on smaller projects, tomatoes could be a good tool to use. I'm not sure how effective it would be on a large scale project where changeseems to be the one constant.

With my components, you can alter all parameters after the fact - add a drawer; change doors/drawer fronts, counts, and reveals; if you change the type of drawer slide used, the drawer box size will recalculate automatically; change material thickness and all affected components are adjusted for you... You can create a model cabinet based on how you build and then store that in your components list. Once it is in that list, you can use it over and over again without having to do any work other than specifying its width - In that respect it is similar to tomatoes.

Paul

-

How do You handle different sizes of the same cabinet - I mean the names. Say we insert cabinet A, then another copy of the same cabinet A, but this time change the dimensions and put a different door. In the final cutlist how we gonna know which parts belong to winch cabinet? Now I'm making the copies unique and use this naming conventions - cab_part#1, for the copy cab_1_part#1

-

Dear Paul,

If you could ensure that your design software applies equally to EU/UK and USA standards, then I'm sure it would be well received. In that respect, Tomatoes might be helpful in gauging the degree of conformity with EU standards. The versatility of your software should appeal to the professional kitchen cabinet designer.

Kind regards,

Bob -

That's a very good point Bob, thank-you, I will look at it again from that perspective. I think you hit the nail on the head regarding your comment about meeting different standards, it is one of my top concerns.

Paul

-

Hi dedmin,

The solution I'm currently using is to have the export program make each cabinet unique. The sub-assembly in the cutlist plus export will contain the unique cabinet reference name (EG. Cabinet(1)). The part that I don't like about doing it this way, is that there is no direct tie-back to the sketchup model.

Paul

-

Yes, that is one of the problems with dynamic components.

-

@watkins said:

Have you seen this?

Kind regards,

BobThis plugin creates only groups with strange names, a lot of reversed faces and the export doesn't group the parts, nor determines width, height and thickness. Not practical at all.

-

@dedmin said:

How do You handle different sizes of the same cabinet - I mean the names. Say we insert cabinet A, then another copy of the same cabinet A, but this time change the dimensions and put a different door. In the final cutlist how we gonna know which parts belong to winch cabinet? Now I'm making the copies unique and use this naming conventions - cab_part#1, for the copy cab_1_part#1

It is possible to have an attribute that is dynamic and uses dimensions/values directly from the model to create the name or attribute.

-

I didn't know that. But what happens to the internal links between nested components? As the position of the shelf is linked to the side and the like?

-

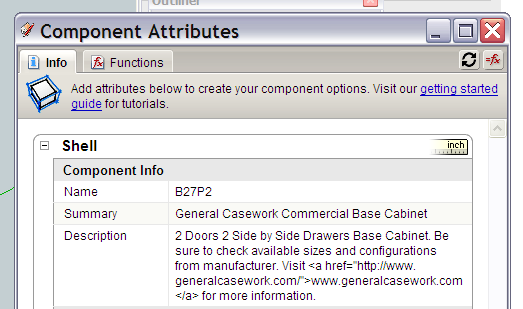

I'm not sure what happens with the internal links, but I think there are 2 names for a component. One being the SketchUp definition name, the other being the DC name. In the following image, the Component Info name is dynamic while the name used internally remains "Shell". This way, the generated name can be used for reporting.

Here is an example of a cabinet whose name is created from the dimensions:

And it's name formula:

=concatenate(if(Type=30.5,"B",if(Type=28.5,"A",if(Type=26.5,"V","D"))),"27P2",if(Shallow_Depth=23.75," ","S"),if(aWidth<>27," (modified width "," "),if(aWidth<>27,aWidth," "),if(aWidth<>27,")"," ")) -

Thanks, Jim. Yes, when the option change, it creates a new component but the names are so messy! Needs a further investigation.

-

Thanks Jim. I use the component info name when I export the cutlist data. I had been searching for a way of getting a unique cabinet number to attach to the name when the DC gets created. I was hoping to reference some external component (like a project file DC), but haven't had any luck figuring out how to do so.

Maybe the solution to this problem lies somewhere between your thoughts and what I'm doing currently (creating the unique name for export purposes only). Maybe I should be actually updatingthe cabinet DC's via a ruby script and generating a unique name at that time. It could be an option when the export is being generated. If the option is ignored, the system would still generate the unique numbers for reporting, but would not update the model. I think that's an acceptable workaround. thoughts?

Paul

-

I think the names of the parts in the model and in the report should match. If we have a shop drawing with labels showing the parts, and a labeled parts already sawed and they differ? It will be confusing at least. This is very important here - because this melamine boards look so identical!It is not like real woodworking - when You see a leg, You know it is a leg!

-

I have put a new video up today. As always any comments and recommendations would be most appreciated.

-

@unknownuser said:

I have put a new video up today. As always any comments and recommendations would be most appreciated.

Palo, see this demo videos - http://www.youtube.com/user/bazissoft#p/u

This is a Russian program for furniture design - it shows the way we are working here.

-

Thanks for the link dedmin. The features demonstrated in the videos would make good additions to the software and I think it would make sense to plan for some of these in future versions.

The two main features that I liked were:

-

Architecural line drawings. These kind of documents are crucial if you are bidding on commercial work... as well as for forming the final specifications of any contract. At this time, I rely on Layout to provide this capability, but I would love to have this done automatically for me.

-

joinery hardware and placements. My software assumes that the cabinet builder will use their own methods for determining this (jigs, measurements, build notes, knowledge...). Programatically, it presents some challenges to try and implement this within the current feature set of dynamic components. A few months back, I submitted an enhancement request to the Sketchup team that would make this a relatively simple matter... I'm hoping that the level of complexity for SU to provide the feature won't be prohibitive and that it might fit strategicaly for growing their product.

What were the things that interested you the most, and which ones do you think are critical for the initial release?

My goal for the initial software release has been to provide a basic product that can design/layout cabinets and whose generated cutlist can be trusted regarding material, dimensions, grain orientation and banding. All placements and methods of joinery (dowels, biscuits, RTA fasteners) would be outside this domain. Perhaps my scope is too limited to make a good first release... it would be interesting to hear the viewpoints of others.

For those interested in my videos, I have done 3 to-date and plan more for the future. Please check my channel (http://www.youtube.com/user/CabinetSense?feature=mhsn) from time to time.

And as always, I welcome everyone's comments and views.

Paul

-

-

Hi Paul,

Glad You keep up improving your work. I think the most important features are banding, grain direction and above all good reporting capabilities! In SketchUp is pretty easy to build and change cabinets, but exporting valuable data for production is a big pain that kills the speed of working! So far there is no good data exporting plugin - lots of data inside dynamic components, but no way to get it outside for further usage! Problems with non english characters, only inches and etc. Another big problem is managing copies from the same cabinet - this is very important when working with articles.

After lots of trials and errors with dynamic components I changed my way of working drastically - I don't use dynamic components at all. Only use components at the top level - say cabinet or drawer assembly. Everything under is groups - it is so easy and refreshing! No messing components, changing names and etc.! Now I can have part "top" inside "Cabinet1" and in "Cabinet2" and they are independent!

I put the banding after the group name - "top;2W-2L" and CutList plugin takes care of the rest. With groups You can select all with the same name and change the banding at once - big time saver. -

Hi dedmin... good post. I agree totally with you in regards to the way SU handles duplicate dynamic components... I sure wish there was a way that you could just turn that off. It's vital that one understand how DC's work in order to avoid "unwanted" surprises. IMHO, though, they are still a very worthwhile and versatile feature.

I've taken the comments that you and Jim have provided me and have made a number of changes to the way my software works:

My export script now gives you the option of renumbering any duplicate cabinets and synchronizing it back to the SU model. I have taken Jim's advice and concatenated this information into the component info name field. When you pull up the DC's component options dialog, it will now display "Cabinet 1", "Cabinet 2"...

With regards to banding, you declare the banding requirement as none/primary/secondary for each side on every cabinet piece (EG. top, deck, left end...). What you can now do is substitute banding material names at export time. My software has a job DC that allows you to specify a number of things including what banding material should be used for primary and secondary. If I have a standard cabinet that declares which edges need to be banded (primary or secondary banding), the actual banding material used could vary for any job that i'm doing... so I now can record that for a specific job (eg. a kitchen that has 30 cabinets) I will use white pvc edgebanding as primary, and oak wood veneer as secondary. At export time, the banding info will be specified using your codes (WPVC-OAK-0-WPVC) instead of p-s-0-p. If you choose not to use the banding material substitution... the export reverts back to the p-p-s-s cutlist plus format.

I haven't had any problems with the inches internal format for mearsurements. The export program detects which end-user model units is being used and converts all dimensions to your selection. Lastly, I have been able to extract the component options label value from the DC. This will allow me to use this value (which could be non-english) as the report header for any exports. I believe that is what you were wanting.

Thank you for all the feedback that you have given me... I appreciate it very much.

Paul

-

Excellent news! Seems You fixed all the problems - it is gonna be a fine piece of software! Maybe I didn't dig too deep inside DC, but my work wary deeply and DC are not very practical. Actually if Google improves them they gonna be a killers - especially for cabinets. But I guess knowing ruby helps a lot in your job.

I'm happy to see more knowledgeable people considering SketchUP as a platform for intro-mid-range furniture software! There is a big demand for a such easy, user friendly and inexpensive software! We have here some programs based on AutoCAD that cost more than SketchUP and they output data to Excell - so, the final cost is huge - software, AutoCAD, Microsoft Office, cutting software! And AutoCAd is so slow and bloataware - who needs 200 options for the dimensions? After all furniture is not so complicated! -

Hello Everyone,

I've been busy the past few weeks enhancing the software and have now finalized my first release candidate. I will be doing final testing over the next couple of weeks and when I'm satisfied with the stability of the product, I will be releasing it into beta test... and that's where you can help.

If you have experience building or designing cabinets and have some time that you could devote to giving the product a run through, I would love to hear from you. I can only manage communicating with around 10 testers, so if the response is larger than that, I won't be able to accommodate everyone. Please PM me regarding your interest. Any information you could provide regarding the style of cabinets you build (frameless vs FaceFrame...) and methods used would help me choose a team with the widest variety of knowledge.

thank you... Paul

Advertisement