Connecting Wood Beams to Steel Pipe Sections

-

Oops. posted to wrong thread!

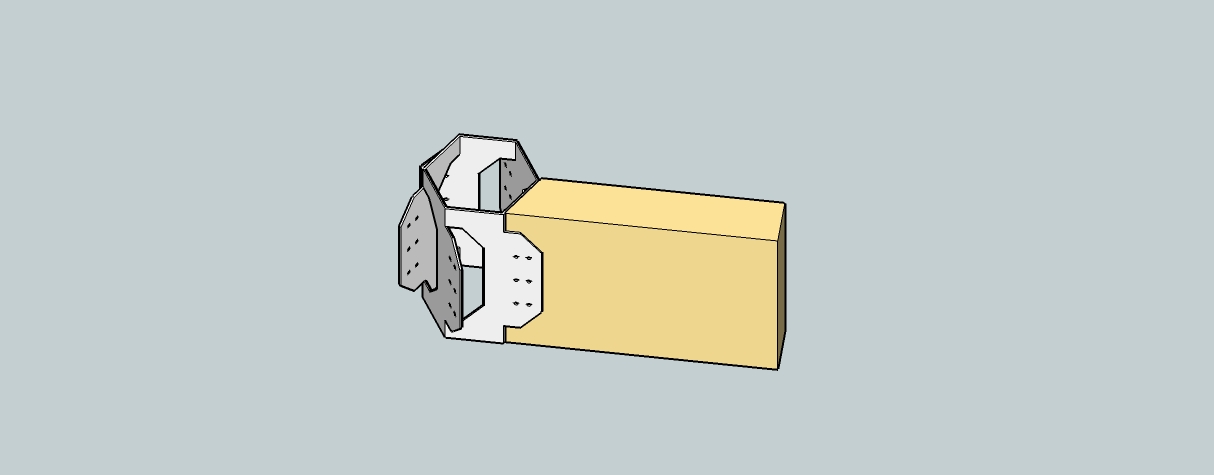

Not sure of the loads involved, but this might work, if you could find a simple way to connect them to the pipe. The advantage would be the ability to bend it to any angle.

Simpson will also make custom connectors, for a price.

Tom

-

@unknownuser said:

Fred

On your previous post you show a connection with 6 sides. However, here you show 7 sides. Have you changed the design?

Just enjoying your project.Ken

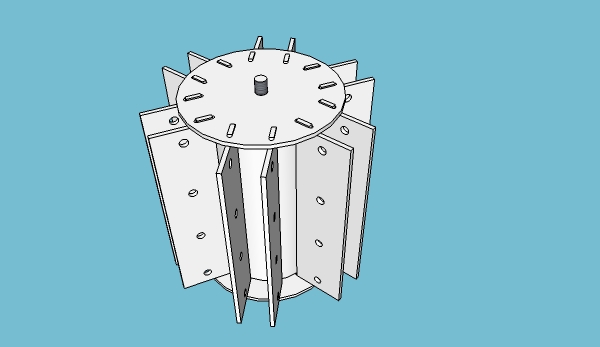

Ken, Thanks for the comment. No design change. In rare situations you might want the hub to support 7 beams. Just a version showing that possibility. In almost all cases the hubs would support either 5 or 6 beams.

-

Simpson will also make custom connectors, for a price.

Tom[/quote]

Tom, Thanks for the Stimson lead. I'll poke around their site and see what I can find. Fred

-

Fred,

A lot of the Simpson line, including the LS series, is available at Lowe's & Home Depot.

Do you plan to support these structures on vertical walls? That would solve one of the biggest drawbacks of the dome concept.

-

@wootton said:

Fred,

A lot of the Simpson line, including the LS series, is available at Lowe's & Home Depot.

Do you plan to support these structures on vertical walls? That would solve one of the biggest drawbacks of the dome concept.

Tom, I've perused the hanger section of our local Home Depot but haven't found anything appropriate, or even something I could modify. I'll see if there is a place on the Simpson to inquire about possible products.

I do plan on supporting the roof structures on vertical walls. I totally agree about that being a drawback of many domes.

-

Dear Fred,

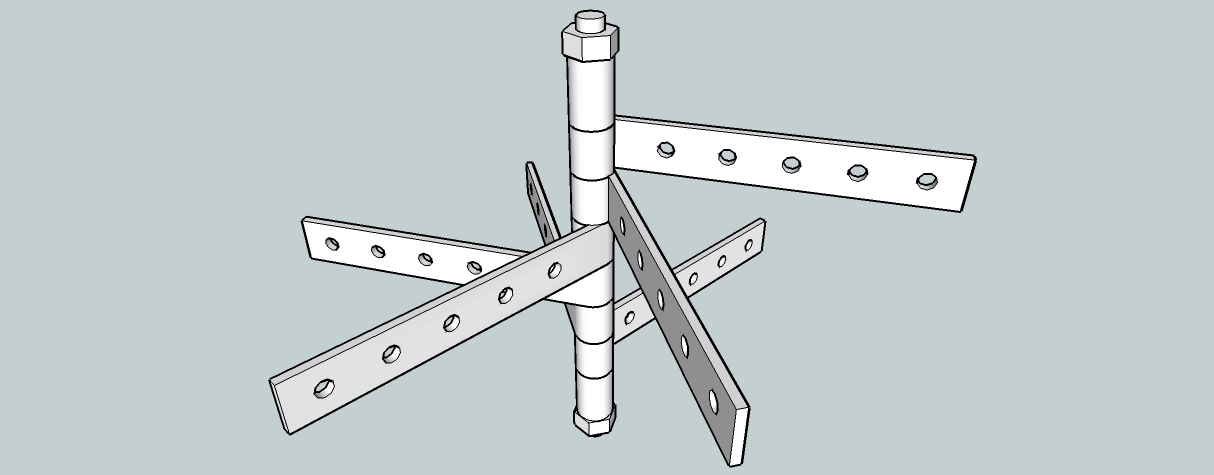

A quick sketch showing your idea realised in sheet metal and tubing. I have drawn 3 mm thick parts, but you could probably get away with thinner material (1/16"). The radial locators are spot welded to the slotted flanges. The threaded rod is a press fit in the bottom flange, and the inner tube is to stop the slotted flanges from buckling when the M8 nut (not shown) is tightened up.

Regards,

Bob

-

Dear Fred,

I have just thought of a simpler solution that requires fewer parts. All done in punched and folded sheet metal parts and stock tubing. Will draw it up tomorrow.

Regards,

Bob -

-

wootton and watkins... (sounds like a law firm)

Very creative solutions guys! Thanks for sharing them.

Here is the deal though. Each hub has beams coming out at different angles and slopes. Each hub needs to support a unique pattern of beams. Some hubs need to support 5 beams, some 6, and in rare cases 7. Hangers that can be slid around the circumference of a tube provide this flexibility. I've attached the SketchUp model I used to design the roof so you can see this more clearly.

-

Fred, have you considered solid dowels instead of tubes, in conjunction with some "steroid enhanced" version of the Kreg pocket hole jig for the rafters? If you could size the pocket jig for 1/4" or 3/8" lag screws, and make the dowels out of engineered lumber such as versa-lam, you could develop a pretty predictable load capacity. Versa-lam's strucural values are mostly higher than the wood they're made from, with grain & knot variability eliminated. It's pricey compared to dimensioned lumber, but not compared to steel. It comes in beams and columns, so you could get 4x4s or 6x6s and turn them. They would probably sell you octagonal shapes or even dowels if the order was large enough.

Here's a link to the columns (page 8 of the PDF):

Tom

-

-

Wooten, I like the idea of using a wood dowel and something like pocket holes. Cool approach, and very pure from a wood working perspective. My brother, who does a lot of fine wood working, suggested something similar. It would involve a lot more work than the joist hanger approach but the result would be elegant and beautiful!

Advertisement