Custom Part Creation

-

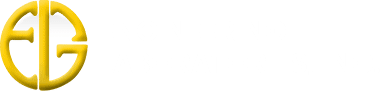

So after two days of not being home to sign for the FedEx delivery I finally received the parts from Harvest Tech today. For some reason my initial reaction was that they were smaller than I was expecting but they are in fact perfect (thanks again to Bob Watkins for creating the CAD file). The next step is to make some molds from these prototypes and see if I can reproduce the parts using Ductal. I found what I think is just the stuff for making the molds from Areo Marine Products.

-

Dear Fred,

Glad to see that it all worked out.

Regards,

Bob -

Yeah, looks very good. Keep us posted.

-

Dear Fred,

You can also buy off-the-shelf plastic balls:

For my development model I would drill and tap the plastic ball to take a wire-thread insert (http://www.emhart.com/products/helicoil.asp). The insert would increase the durability of the thread, making stripping out less likely.

A production model might use moulded-in fittings (for example http://www.anchorinserts.co.uk/)

A one piece moulding (ball and attached arm) might also be possible.

Regards,

Bob -

Bob,

Thanks so much for sharing the leads!

Since this "system" is open source I hope that you and others will be interested in trying your own variations on the theme. One of the cool things about the system is that it is scalable. When I first got interested in TINs I thought they would make a great building toy and still do. In this entry to the Buckminster Fuller Challenge I tried to make the argument that a TIN building system (or toy) would help people think outside the box. (BTW, there are a lot of interesting design proposals on the BFC pages.)

I'm focusing now on a version that could be implemented with inexpensive materials by local craftspeople, but that is just one of many possible paths to explore. If anyone is interested I would like to consider working with a few people to develop a proposal for the 2009 International Development Design Summit.

Fred

-

what **production material **are you thinking of, fbartels ?

-

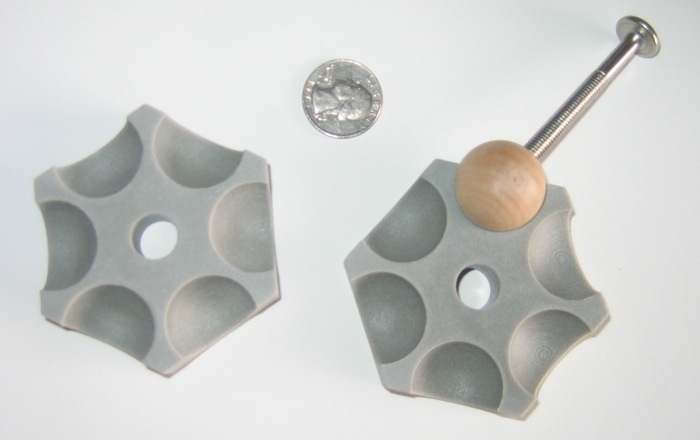

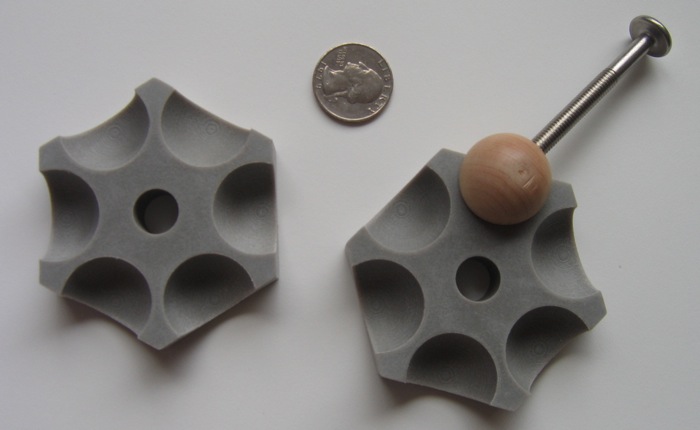

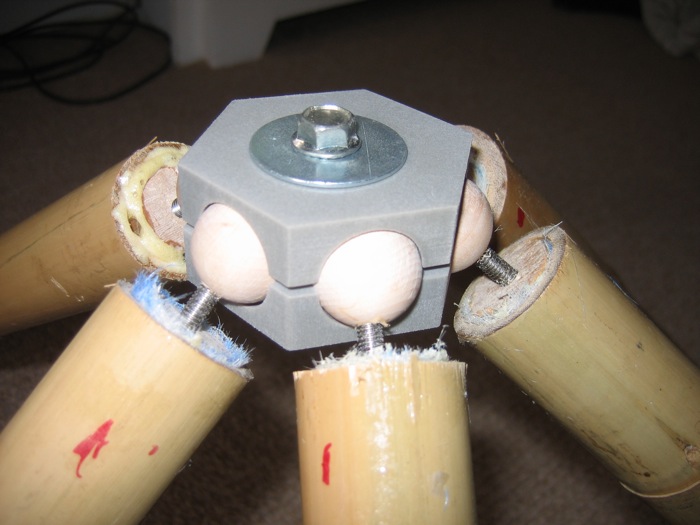

First test of the part. The photos pretty much tell the story. No surprises in terms of the pieces going together as designed.

I didn't put much stress on the hub because I definitely don't want to break the prototype. When (and if) I'm able to reproduce the part in a production material then I'll really tighten up the bolt and stress test it.

-

@juanv.soler said:

what **production material **are you thinking of, fbartels ?

Juan,

As I noted in an earlier post I want to try using Ductal as its cost is within my limited research budget and it just might work really well.

Fred

-

cant it be softened the prototype with Ductal ?

i did not know it. thanks for the link.

and a great work of investigation you are making.

cheers -

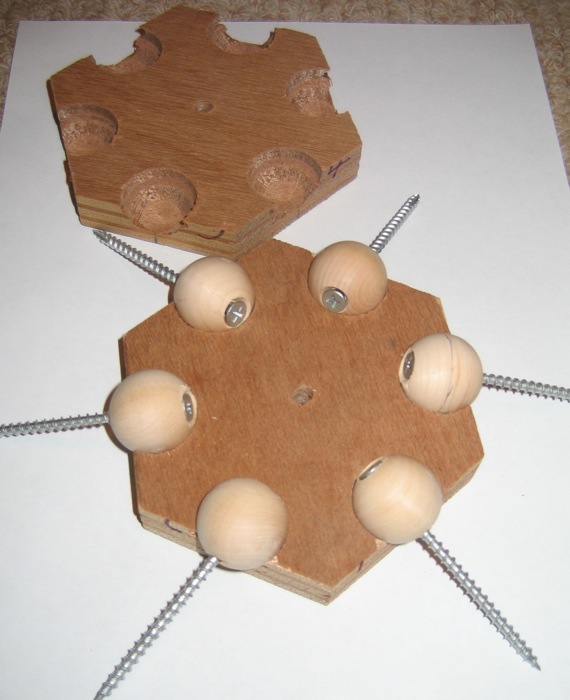

After letting this lie fallow for quite a while I had an idea to try a slightly different approach. Using a round router bit I've been able to make half-spherical holes in plywood hexagons. With the help of the wood shop teacher at my school I've come up with a jig idea that should allow me to make these hubs reasonably easily and quickly. I'm going to try making a few over our upcoming March break. With those I'll see if I can't make a prototype curved roofing section using 2x2 deck rails as the spokes and half-inch plywood for the triangular faces.

-

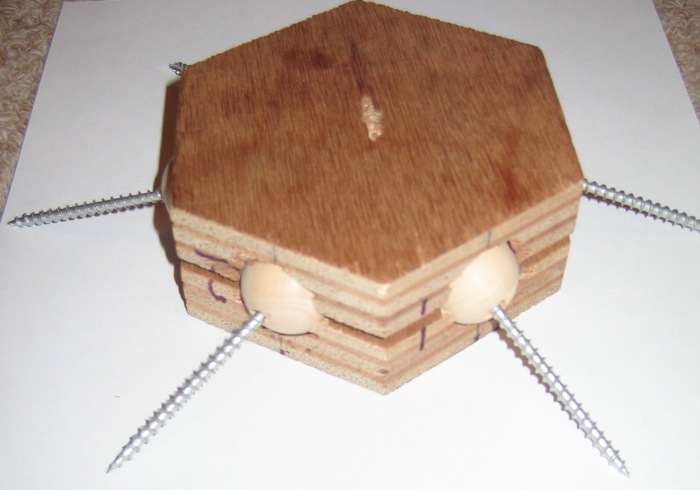

Just to bring the ongoing saga up to date.

I made six more of the hexagonal hubs out of plywood. (As an aside, let me state that it is a lot easier to build things in the virtual world of SketchUp than the real world of saws, drills and wood... and I have the bandaids to prove it.) The jig I built to assist with creating the hubs helped but I'm not able to cut the hexagons to the tolerances really needed to make the jig work well.

Anyway, I put everything together yesterday, glued it up and tightened up the bolts. I am quite pleased with the results. I now have a prototype of a structurally solid wooden TIN. I can stand (all 200+ pounds of me) on the center hub and the TIN barely flexes. Next step is to cut triangles for the faces out of 1/2" plywood.

Advertisement