Epoxy Foam? Need help finding the right filler material.

-

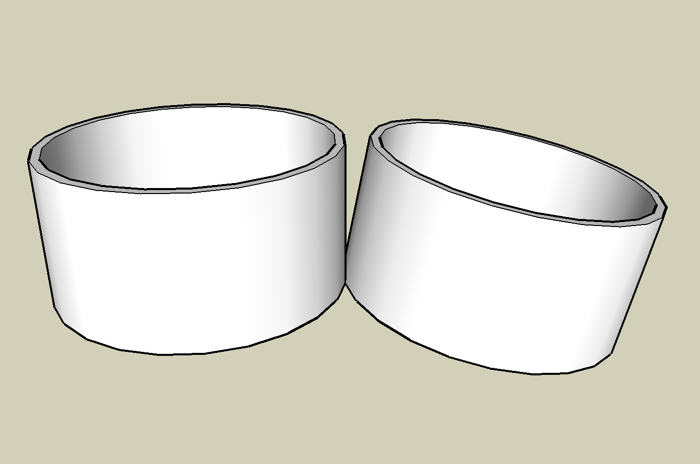

This afternoon I injected foam (Great Stuff brand) into the interstices between the PVC pipe sections, and although this tightened up the structure quite a bit the cured foam has too much give to work really well for this purpose. What is needed is an inexpensive light-weight material that can be easily worked into the spaces pointed to by the red arrows and which will harden up to about the consistency of hard plastic.

I'm considering epoxy but would greatly appreciate other suggestions.

Thanks,

Fred

-

Epoxy is pretty expensive, but it should work. Scuffing up the exterior of the PVC would help from a mechanical grab.

You could also consider pouring PVC cement (ala syringe) where the sides meet. That would REALLY rigid it up.

Todd

edit: Acrylic might work too - not sure of the cost.

-

Thanks Todd. Good suggestions. I'll definitely take a look at PVC cement.

Fred

-

Just thinking about pvc cement...

I imagine that to build a dome out of the short pvc-pipe sections you could have foregone the ties completely. Imagine if you had made a jig that was a curved triangular surface representative of one triangular module of the ultimate dome. Then you could have just laid out the pipe sections on that jig surface so each piece's lower edge was in contact with adjacent pieces. They could have been glued in place as you go or afterwards by injecting a few drops of glue at each junction. Ultimately you would just use the jig to produce all the 'triangle' components that would then be assembled on-site.

And now to really think outside the box...

Imagine if you had just designed in 3d (SketchUp of course) one module of a repeatable component and then used one of those rapid prototyping solid 3d printers to fabricate the piece. Then make a mold and cast all the pieces for your dome. All the pieces could be designed to mechanically interlock. The design potential for this technique seems endless.Regards, Ross

-

Ross,

Interesting idea to get rid of the wire ties. I'm going to give that a try. It would certainly make the whole process go faster.

I'm after irregularly curved surfaces so I can't make use of your great idea to create interlocking modules. Maybe someone else will give it a try.

Thanks for your help!

Fred

-

Take a look at liquid bartop epoxy. It isn't cheap, but it will do exactly what you are looking for.

It dries completely clear, pours like a liquid, and glues like an epoxy.

It is a 2 part product; I use it extensively to fill in cracks, voids, and knot holes in antique wood.

Though epoxy foam would be an awesome product!

-

That bartop epoxy is good stuff, I agree, but wouldn't it add a lot of weight to the structure? Have you considered using another section of PVC pipe cut at the same length and with a diameter that would fit in the void? I would think this would add to the rigidity and reduce the amount of epoxy needed.

-

Good point about the weight, I hadn't thought about that.

Just another thought. When you used the Great Stuff foam, did you use the kind suited for filling big voids, or the one made windows and doors (minimal expanding)? The window and door version is much less rigid than the other.

Since they make panels with spray urethane, I am sure there must be a version that is rigid enough for you. Perhaps having an insulator look at it let you know if there is a foam product that would work better than the Great Stuff. I would think that spray urethane would be a better long term solution than the epoxy, if you can find a rigid enough product.

-

Eric and Chuck,

Thanks for your assistance. Eric, I used the Great Stuff version for big voids. The foam just doesn't have enough density to resist compression. As I put pressure on the PVC cylinders I can see the foam compress.

Chuck, the smaller PVC tube filler idea would be difficult to implement because of the variation in the void size due to the cylinders not being parallel to each other.

Apparently epoxy can be made significantly lighter by the inclusion of various additives. See the bottom of this page. http://www.jgreer.com/

Another possibility is high-density foam. See this page. http://www.rhhfoamsystems.com/systemhigh.php

I'm contacting both companies to see what they think.

Thanks again for your help!

Fred

-

The epoxy guys will have to know the intended objective of the use of the item before they can recommend an appropriate filler. I use West System Epoxy and they have a whole line of fillers for different purposes, with Colloidal Silica being the one that comes to mind for a lightweight filler.

Todd

-

Hi Todd,

I just had a very helpful conversation with John Greer, apparently an epoxy guy's epoxy guy. We went through the various epoxy filler options but it turns out John's company has a very high-density foam (not shown on their website) which I'm going to try next. When that arrives I'll give it a shot and let people know how it works.

Thanks,

Fred

-

Fred, what about the foam used to seal waterfalls and fountains? I know it doesn't have a ton of give, since it has to resist settling boulders.

Advertisement