Bamboo Roof Structure for Open Architecture Challenge

-

I've been playing around with an idea for the Open Architecture Challenge which involves a curvy roof.

The roof would be supported by a TIN like hexagonal mesh of bamboo struts. The hubs would be very simple. Three pieces of extruded aluminum wire held together with a wrapping of steel wire.

The ends of the aluminum wire would be glued into the hollow ends of bamboo struts, creating structures like this.

I've been really struggling to come up with an inexpensive material to layer over the TIN, which would in turn support the roof membrane. I think I want some kind of honeycomb like structure that could be filled with expanding foam. Last night I had the thought that if you cut bamboo poles into 2-3" long sections, you could connect these sections together with plastic wire wrap and build a strong but flexible honeycomb like structure.

I'd appreciate thoughts, feedback, reality checks.

Fred

-

Nice work fred, nice to see some really new stuff.

My thoughts on the project are mostly positive, i really like the idea, its right up my street. My only concern would be with your idea for the supporting structure to hold the membrane, the honeycomb bit. It seems like a good idea in practice, but i think if you were to try and manufacture it, itd be a nightmare.

perhaps if you cut lots of longish (1m) strips and then used some sort of backing materail to get something you could drape over the roof?

good luck with this, i hope you win the comp

-

Remus,

Thanks for the feedback and the strip idea! I agree about manufacturing the bamboo honeycomb. However, the OAN folks are looking for systems and processes that can be built locally with mostly locally obtained materials. If the bamboo honeycomb were built as a community effort -kind of like barn raising back in the day- then it would be quite doable and people of every age and skill level could participate in the "weaving" of the mesh. I'm going to get a hold of some appropriate sized bamboo over the next few weeks and try some experiments. I'll let you know how it goes.

Could you do a quick SketchUp model of what you have in mind for the strips?

Thanks,

Fred

-

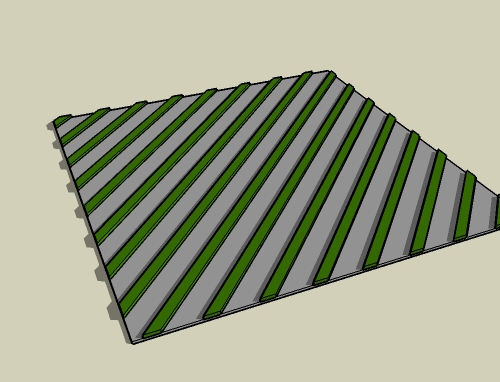

this is the sort of thing i was tihnking of fred. Thinking about it in a bit moe detail, im not sure fo this would drape over the roof well enough, depends how small you made the strips i suppose.

-

as a carpenter by trade, when i hear roof mixed in with Glue, wire, and bamboo, i get scared..

-

jeff, not to worry, i forgot to mention the duct tape! fred

-

haha..

-

I don't know if this idea is worthy of any development but the first thing I thought about when considering how one might cover such a frame was...

Papier-mâché

Perhaps a papier-mâché approach could be done with fabric strips or heck, perhaps even old newspapers. Here's an article about papier-mâché boats -- it shows that Papier-mâché isn't just for crafty kids projects: http://kcupery.home.isp-direct.com/SH.html

Regards, Ross

-

Ross,

Thanks for responding. Interesting idea regarding the paper mache. There would need to be some sort of waterproof membrane (sheets of the boat-wrap type plastic?) on top but the combination might work nicely.

I just returned from Home Depot with 3 10' tubes of 2" diameter PVC plumbing pipe. I'm going to experiment with this as a substitute for bamboo. Here in the suburbs of NYC it is cheaper and more readily available.

I'll have some pictures in a day or two.

Thanks again for the feedback.

Fred

-

Have you considered splitting the bamboo in half length ways in 1 or 2 ft sections and lapping them like roof tiles? I dont know if that would even be something to consider or not, but it would give a person on the sideline something to do till the roof frame is finished. Is that what you have in mind with the PVC?

-

how would that work with freds curvy roof

-

How about a heavy duty 'bubble wrap'? It could work as an insulator too and be able to drape to form.

-

I started putting together a prototype honeycomb membrane with 2" PVC pipe and wire ties. Although it may not look like much in these pictures, I think it is quite promising. I'm keeping the wire ties loose for now because I'm going to form a curve with the membrane and therefore want it to be flexible until I settle on the shape of the curve. Once I've got the membrane in the desired shape I'll inject expanding foam into the interstices between the circles and tighten up the ties.

Mike, the pictures should explain what I'm doing with the PVC. Pete, in theory I like the bubble wrap idea but implementation might be tough. What happens when the air starts to leak out?

The third image is of the simple jig used to mark where to drill holes for the wire ties.

-

looking good fred, im thinking about retactign ym comments aobut it being difficult to manufacture now

-

Remus,

It's pretty tedious cutting the cylinders and drilling the holes but if you had the right tools and jigs it could go really fast. Putting the cylinders together with the wire ties goes quickly and is kinda fun.

Fred

-

The honeycomb structure grows...

The first image shows one 10' tube's worth of 2.5" high cylinders. It took approximately 220 wire ties to connect the pieces. I'm going to increase the size to 36" on each side of the triangle. This is about the size of the triangular space I'm envisioning using for the underlying TIN support structure.

The second image shows the good curvature capabilities of the structure.

Does anyone have a good reference for the various flavors of expanding foam/glue?

-

I finished up the first stage of the first honeycomb structure prototype this evening. It incorporates about 19' of 2" diameter PVC tube cut into 2.5" lengths.

I've become quite attached to the thing, which isn't at all surprising given the hours it took to produce. The next stages are to secure it to an underlying triangular frame, tighten up the wire ties, and then "inject" foam into the interstices.

I stopped by "the home center" again today on the way home from work and picked up more wire ties and a 10' x 4" diameter PVC drainage pipe. The 4" pipe should work better than the 2" for my purposes. It will certainly cover space more easily and rapidly and with less weight.

-

It almost looks like you could forget the frame entirely. Just make a dome out of the bondaged tubes. It also looks like after the foam is injected you could parge the outside of the dome. All those hairy ties would attach the parging to the structure.

On the otherhand the dome without any foam or covering would still be a very interesting structure. I can imagine the light filtering in through the tubes & ties. The coloured ties have become a feature. Now imagine how this would look if you built an entire dome using glow-in-the-dark ties! It would be a thing of even greater beauty. As a landscape element it would also look pretty cool at night with an interior light (say a colour-cycling LED?) flowing out through all the tubes/ties.

-

Ross,

Great ideas!

I agree about perhaps not needing a frame for smaller structures. It would be interesting to try a dome as a group project. Cost of the materials would be only a few hundred bucks. Connecting the pieces with the wire ties goes fairly quickly. However, the hole drilling is quite time consuming.

Lighting, especially colored lighting, could be really interesting because of the reflective white PVC. I'll do some experiments tonight. I moved "the thing" up into the living room where it has the very temporary status of abstract sculpture... my wife's a good sport.

I had to Google "parge" to find the meaning. Always nice to add a new word. The parge idea potentially solves a problem I've been pondering, which is how to put a fire-resistant coating on the inside of the honeycomb. I read somewhere that insulating foam needs to be covered with some material that is relatively inflammable and a parge might be the ticket.

Fred

-

2" vs 4" PVC pipe comparison.

The images tell most of the story. The 4" pipe is a much more viable option for doing something like a roof simply much more space is covered with much less material and effort.

Advertisement