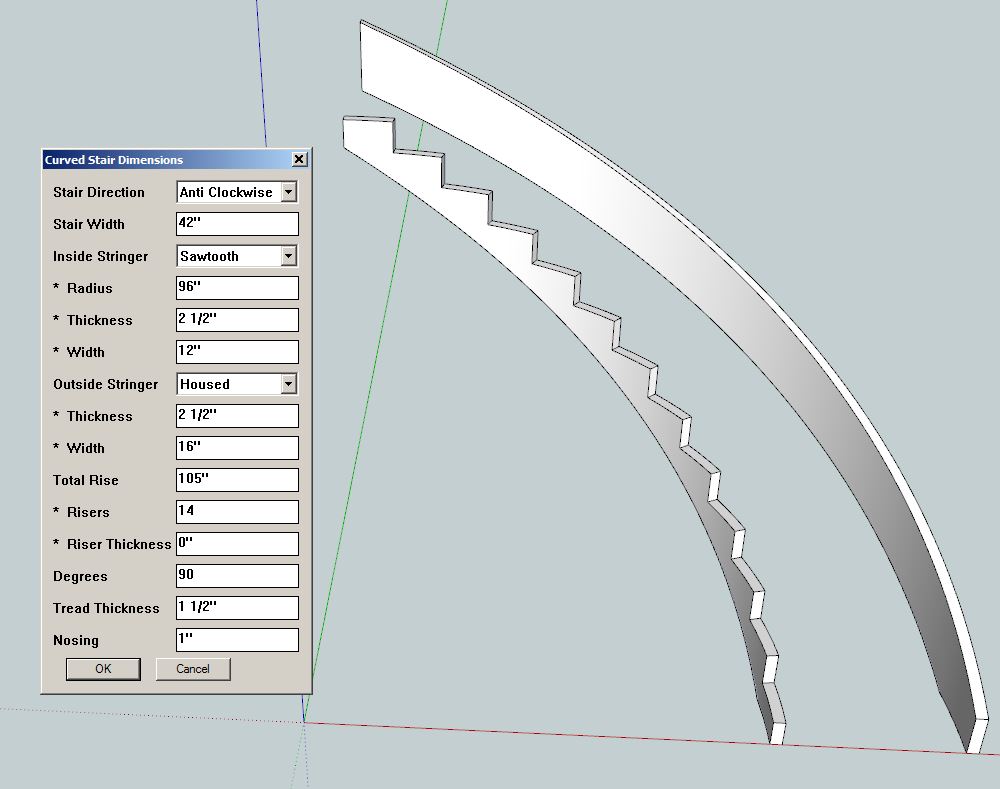

Curved Staircases

-

Yes it sees what your setup is at startup and stays with that - metric or imperial.

You are stuck with that choice until next startup.I've got the plugin working so there aren't any extra faces that need to be deleted.

The soften tool shows that up in a hurry.I have the sawtooth working for open risers (set Riser Thickness to 0.inch or 0.mm). I need to adjust the sawtooth for risers that have thickness.

The Stair width will be overall width of stair which includes the stringer thickness if housed and includes the tread overhang ( same amount as nosing ) if sawtooth.

The only extra work that I have done so far is orient faces and apply the softening.

Not a real big problem.I want to add in stringer feet and stringer heels which will represent a fair bit of work.

So I'll probably go to treads next. I will create a curved tread as component and then copy rotate and move ( which I believe are transforms - I'll find out when I get there ).

-

That's fantastic Garry... Very exciting.

-

I had a bit of issue with some coding - but I believe that I am past that now.

In the mean time. Here are 2 more stairs. The first one has a single center stringer that I set to 120 mm thick and 400 mm wide. The treads are 3 layers of 3/4 plywood glue laminated - so I set the tread thickness to 57 mm. I set the outside stringer to none so it wouldn't build it.

Notice that I told the plugin 0 for riser thickness. I built the stair and then deleted the treads. I did add texture to the stringer and then when the treads were created I added texture to them and then I uses the round corners tool to ease all the treads to 1/2" bullnose.

I ran the plugin a second time ( it remembered all my settings ) and changed the inside stringer to none as well as the inside. I then changed the inside radius to 2400 and built the stair without stringers on top of the first one.

The second stair is an example of an outside concrete stair. In this case I set the outside stringer to none and turned of risers and treads by setting their corresponding thicknesses to 0.

-

Here is an unusual stair case. Anyone up for this challenge?

-

and I thought I was strange...

-

Plugin is at the next stage. Treads and Risers are finished. Notice that there are still some things to do. The Housed stringer at the bottom and at the top is not finished. I need to extend the housed stringer 2 X Nosing. Also the Nosing on the top riser is missing.

I've added a floor thickness which currently makes the top riser board flush with the floor.

Also added a stair_defaults.txt file which contains a few items that aren't controlled by the input box. Every entry in the input box has a metric and an imperial entry in the text file. So you will be able to set your own defaults like tread thickness and dado values etc.

The Plugin does not bullnose (round over) the treads. I've use the Round Over 3D plugin to accomplish this task as it only takes a couple of minutes. For a sawtooth, housed stair with riser boards I first drew a vertical line on the back of tread 12.7mm from the inside curve.

This is to control the extent of the round over. I then picked the edges that I wanted to round over and then performed the roundover. Notice that it does work properly where the riser board dado is. Just make sure that you pick the edges as in the picture.

-

Here is what the stair_defaults.txt file looks like.

-

Top nosing and extending housed stringers are now working.

Here is a 180 degree housed, stair with open risers.

To make the handrails I set both the Riser Thickness and Tread Thickness to 0. I then adjusted both stringer widths and stringer thicknesses to 90 mm. This tells the Stair Maker plugin to build handrails and have the tops of the rails at 800 mm above the nosings which is building code for indoor residential stairs.

-

I have created a video on you tube

http://www.youtube.com/watch?v=TQ94u6bpLq0 -

that would save me like 3 hours... or maybe more.

-

You must be pretty fast. It was taking me the better part of a day to draw stairs. Perhaps because of the amount of detail that I was interested in.

Did you view the You Tube video? What did you think of it? Do you have any suggestions or comments on what I have done so far? Have you been to my website?

-

I have been to the site, but I was looking at the cabinet program... you should have your website in your signature so people check out your great plugins from where ever they might be reading your posts.

I watched the video and it seems really easy to use and straight forward. It will be a great time saver and make for a cleaner group of geometry as well. I don't have any thing to add, it seemed really straight forward.

As for time to build the stairs, it doesn't usually take too long, especially for regular curves.

- I draw everything out in a 2D plan view.

- Then separate into a few groups; stringers, rails and steps.

- I push pull the steps up to their desired riser heights.

- Then I push pull the stringer up to the height of the top landing stair.

- Then I use Curve Shearing plugin to cut out the stringer top line, then copy that line down the depth of the stringer.

- Repeat for each side of the stringer.

- Then intersect the planes with the Curve Sheared lines.

- Delete the unneeded faces.repeat for each stringer.

- Then I use the "From Contours" native SU land drape tool or Fredo's Curviloft to make a top and bottom side of the stringer.

- Repeat for each stringer.

- I used to repeat that process for the rail but now I use Instant Rail and it gives me all the kool options and details for the railings.

- then I push pull some bullnose and call it done.

-

I've got the cleanup working to simulate stringer routing for housed stringers.

I'm going to add a configuration variable so that you can adjust the height of the housed stringer. There may be times when you want the housed stringer higher - so more of the stringer would be visible above the treads.Next step is to see what I can do about bullnosing the treads. I'll add the bullnose radius to the input box.

After that I'm going to look at flaring the treads. I'm thinking that a progressive flair of a flair amount like 1/2" might work well. Say you want to flare the bottom 6 treads - you would end up with the bottom tread flared out by 3", the one before at 2 1/2" etc.

Then add straightening of the outside stringer at top, bottom or both and optional straightening of the inside stringer.

There is also the idea of what I call a notch - this is where the stair starts out between 1 or 2 walls and part way down the stair one or both walls are now only below the stair - allowing for spindle railing. In this case the stair gets wider by the appropriate amount based on the thickness of the wall and the type of stringer.

Any comments?

-

Looks good. Sorry, you're so advanced at this I couldn't add anything.

Kris "Instant Rail"? Is this "Instant Wall" or has Chuck refined the rail functions???

-

Instant Fence/Rail is different... but the same. different plugin but same basic features just many presets and few more/different options.

-

My only comment Garry, is Kick Ass!

-

I call the top of the stringer that continues under the floor the heel. There is now an option for "has heel". I've also added in tread bullnose.

I've added building code information into the defaults.txt file. Minimum Rise, Maximum Rise, Minimum Run, Maximum Run, Minimum Stair Width etc. The defaults are currently set to Canadian National Building code but can be modified for your own area.

The stair maker plugin uses these values to adjust things like number of Risers so that the stair will still meet code.

I've also added in more 0 value settings. If one of the following 3 values is set to 0 then it will be calculated. So you only need 2 of these: 1) degrees, radius, Run at walk line.

I've also added in a setting in the defaults.txt file to finish off housed stringer(s) at a certain height above the floor. I set it to 12.7mm in the picture.

You can run the Stair Maker a second time set as if you are creating a handrail (0 riser and tread thickness, housed inside stringer and no outside stringer ). Adjust the radius by the thickness of your stairs inside stringer. Adjust the thickness of the inside stringer (handrail) to the width of the stair minus the thickness of both stair stringers. This creates a square tube that can be edited and pulled straight downwards ( on blue axis ) to form a finished stair bottom.

-

"I've added building code information into the defaults.txt file. Minimum Rise, Maximum Rise, Minimum Run, Maximum Run, Minimum Stair Width etc. The defaults are currently set to Canadian National Building code but can be modified for your own area. "

awesome.

-

Wow.... impressive!!! I'm still trying to learn how to build a cabinet efficiently. Lol!!

-

Calvin,

Did you by any chance go to my web site? CabMaker32.com.

I am a big advocate on the 32 mmm construction system. You can build very good looking cabinets using these guidelines.

I can also give you many reasons why you will become very efficient. This system is scaleable. So if you are a one man operation or a much larger company you would have to make some tooling choices.

Anyway - if you are interested - we can continue this. We can also take it off line if you wish.

Advertisement