Honeycomb Roof Structure v2

-

Hey Remus,

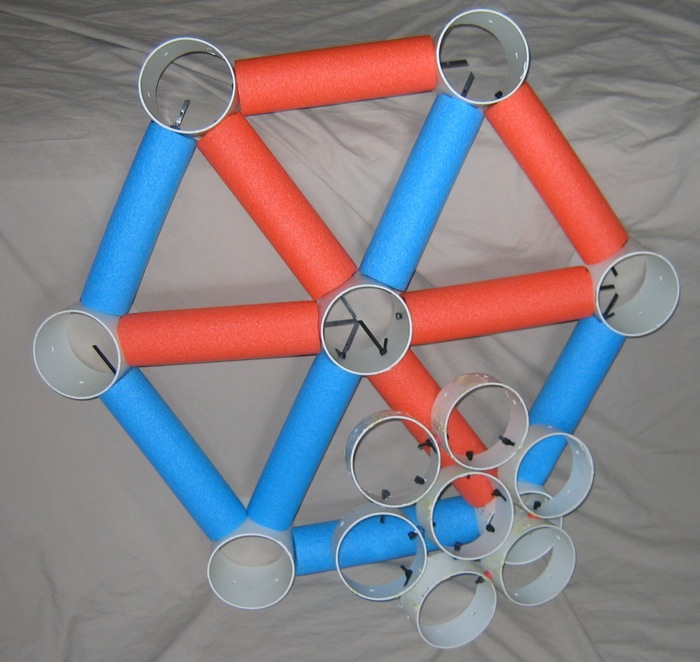

Yes, this is with the high-density foam. I wanted to have a slight bow to the structure so the tops of the tubes are pushed away from each other a bit. With a curvy roof, there would be few areas where the tubes would lie parallel so this would be the norm.

Fred

-

I see what you mean fred, i didnt look close enough at the pics last time so they looked as if all the tubes were parallel

p.s. whats that foam called? looks like interesting stuff.

-

@remus said:

p.s. whats that foam called? looks like interesting stuff.

R, The foam is Polyurethane pour-in-place foam with an 8 LB per cubic foot density. I purchased it from John Greer & Associates.

-

cheers fred, i had a cunning idea for this foam today, i'll have to pick some up at some point and see if i can get it to work.

-

Fred, I totally missed this thread and I am happy you pointed me here...

That experiment is totally amazing and yes, you should go on with it.

I love it. I can see you build a bigger structure in your backyard.As a matter of fact, you are doing the kind of tests Herzog @De Meuron did some years ago whenever they wanted to innovate new material use.

You need to think this through some more.

Don't you think the Polyurethane expanding foam would damage the PVC tubes when trying to make a bigger structure? PU expansion is very powerful you know...

Also, what does it all weigh? What roofing material would go on top as you view it now?Maybe you should post this in the http://www.PushPullBar.com : you will get much more feedback over there as most of the people are architects (or related to architecture).

It would make an interesting thread in the design section.... -

Kwist,

Thanks for the feedback. Much appreciated.

Many of your questions were brought up in a another previous thread on this subject.

To make a larger test structure spray foam is essential. The highest density spray foam I've found has 2lb per cubic foot density. Unfortunately, the smallest unit of this material that's available costs over $400, this is where the wife (and common sense) comes into play to prevent additional research.

I've ordered some 2lb pour-in-place foam and will do some testing with that next week. The foam in the images above is 8lb per cubic foot density.

Fred

-

Thought I'd update this thread with the various experiments I've tried over the past few months.

(The first thread on this subject is located here.)

- I wanted to use up the 8# expanding foam so I made a small domed PVC structure with 2" long sections of 4" PVC drain pipe. It proved to be quite difficult to get the poured foam to fill up the tubing, which I had "molded" by putting it inside a draped sheet of polyethylene. The material takes a few minutes to start foaming and while in a liquid form flows towards low points. This convinced me that for any larger structures spray foam is the way to go. Curiously, the polyurethane foam doesn't adhere at all to the polyethylene sheeting. When I'd used up the foam I put this aside as an interesting failure and went back to playing with SketchUp.

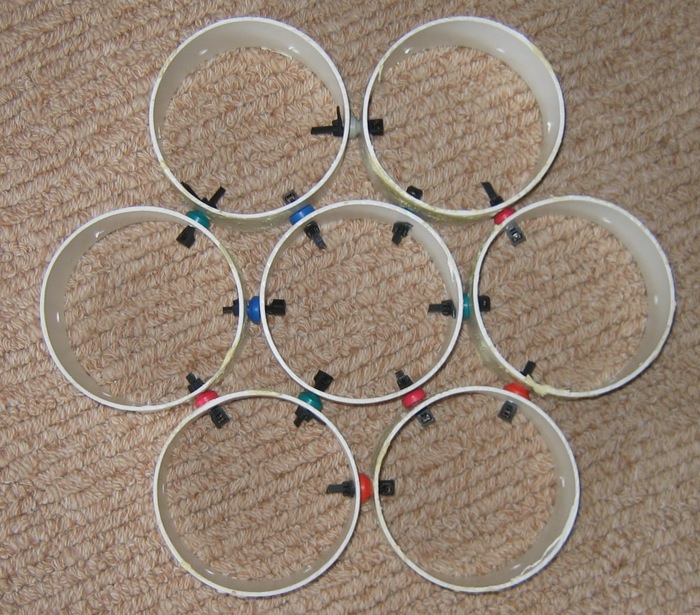

- It occurred to me that having a small pivot object between the PVC tube sections would provide for a more flexible structure (pre foam injection). This insight happened after digesting messages to this thread (http://www.sketchucation.com/forums/scf/viewtopic.php?f=15&t=9982) on complex curved threads.

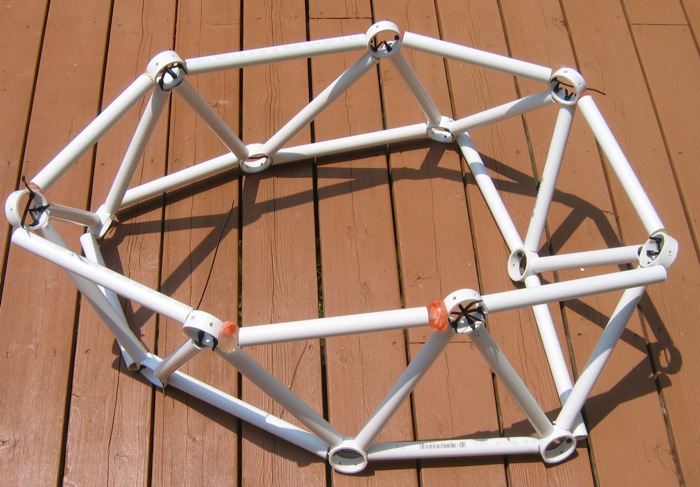

I made up the object in the two images below to test this idea. It has a nice feel to it and I'll use this approach in future experiments.

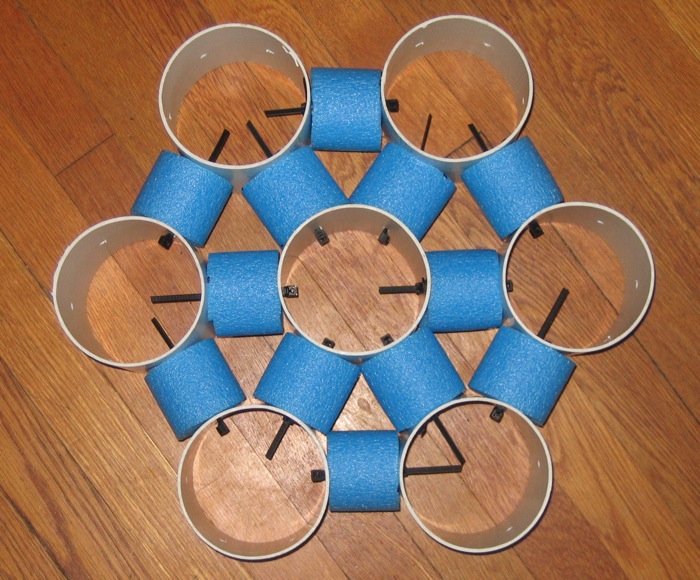

- Next I tried slightly larger pivot objects made of flexible plastic... from a swimming pool toy actually.

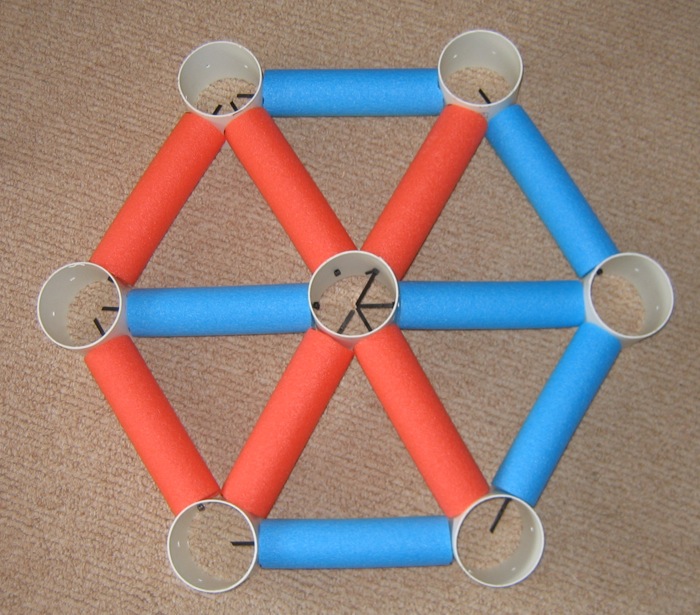

- That was interesting, but made me realize that by expanding the length of the pivot object I get a TIN with the PVC segments as the vertices and the plastic as the edges. So you can get a variety of different shapes by varying the length of the edges.

- Next I thought I'd try experimenting with making an object of about 12" lengths of 1" PVC as the edges and 1" segments of 2" diameter PVC as the hubs. The real limit on edge length is the length of wire tie available. I happen to have a bunch of 14" ties...

I just started working on this object and am still ironing out the kinks. The key kink being that some sort of joint object is needed between an edge piece and hub. I've tried 1" rubber balls, split in half, and they work well but the rubber tends to fall apart when drilled. (It's amazing what you have lying around a house where two boys have grown up.) You can just see these in the second image below. I've ordered some wood half-spheres and I think they will work well for this purpose. The structure is on hold till those arrive.

If anyone has ideas/suggestions I'd be happy to hear them.

Fred

- I wanted to use up the 8# expanding foam so I made a small domed PVC structure with 2" long sections of 4" PVC drain pipe. It proved to be quite difficult to get the poured foam to fill up the tubing, which I had "molded" by putting it inside a draped sheet of polyethylene. The material takes a few minutes to start foaming and while in a liquid form flows towards low points. This convinced me that for any larger structures spray foam is the way to go. Curiously, the polyurethane foam doesn't adhere at all to the polyethylene sheeting. When I'd used up the foam I put this aside as an interesting failure and went back to playing with SketchUp.

-

You are actually re-inventing steel framework, a thing that is documented to extent in structural engineering courses....but in plastic.

I love the experiments on the joints.

A little question: Why use that expensive PU foam and not the cheap version all contractors use for insulation?Do you really need high density foam?

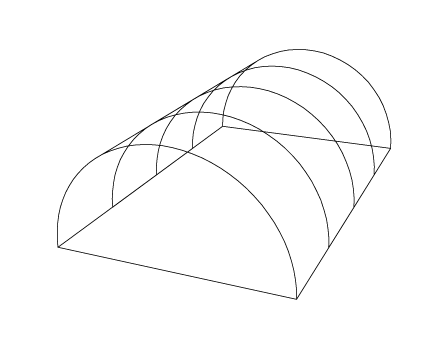

I can imagine the normal PU insulation foam is as powerful (and weighs less).The best way to experiment how the structure performs under influence of gravity would be setting up a tunnel model :

I don't think a little deformation by pressure of the foam should be a problem...On the contrary, it can be an advantage as the structure would gain dynamics to respond to changing variables as wind pressure,snow, temperature variations etc...

[EDIT]: I just noticed that your structure will only be as strong as the plastic straps that hold the pieces to the joints. The strength of the joints is the key to success here imo.

-

I vote Fred calls himself "Bucky" from now on.

-

Kwist,

Thanks again for the feedback.

Plastic is cheap... make that "inexpensive"... so it's much more viable for the home crackpot inventor. All the materials I've used for these experiments have cost less than $200.

Regarding the PU foam. The structure I built using low-density foam had virtually no integrity under load. Since I'm interested in a roof structure that would need to hold quite a bit of load the only way forward, using these materials, is to use higher-density foam.

The wire ties ARE the weak links in the structure. However, there are a lot of options in wire ties. Take a look at this site (http://www.buycableties.com/). There are even stainless steel versions.

@unknownuser said:

You are actually re-inventing steel framework, a thing that is documented to extent in structural engineering courses....but in plastic.

Stinkie... so plastic + bucky ... could be shortened to "plucky".

Fred

-

Good stuff fred, i look forward to the day when i see a house with your roof on it

-

Pluckminster Fuller it is!

Keep at it, Fred. I'm a Miesian grid person myself, but I truly welcome experiments. Cream in the coffee, you know.

-

Good example Stinkie!

Buckminster fuller was DA big example to follow in this matter. -

Fred, this reminds me the architecture of Shigeru Ban. He makes astonishing structures with recycled cardboard tubes combined in a similar way as you do. I hope this can inspire you.

-

Matteo,

Thanks for sharing the Shigeru Ban links and image. I like his work a lot, although not so much the more rigidly geometric shapes. My favorite Japanese architect is Toyo Ito.

I like how Ito combines curved and rectilinear shapes. As a middle child I'm always looking to find the middle ground between extreme positions, in this case the blobbists and the Miesians, and this is territory Ito has been exploring for years.

Ideally, I'd like to be able to obtain viable roofing structures similar to the one in the following image (another Ito building) using mostly PVC and Polyurethane foam. It's a long shot but that's what I'm aiming for.

Fred

-

-

Latest Plucky Adventures...

The wood half-rounds and balls I ordered from these folks (http://www.craftparts.com/) arrived, as did some 17" heavy-duty cable ties. I put together two hubs and an edge section last night and it looks/feels pretty good. I hope to do some additional work with the pieces this weekend.

As I've been working with this stuff I keep thinking that a similar structural system could be implemented using bamboo in place of the PVC, and hemp rope in place of the plastic wire ties. This would give you a completely organic structural system, using materials that would require only simple and low-energy processing and that are locally available (growable) in most of the world. Interesting.

Advertisement