Custom Part Creation

-

Dear Fred,

Glad to see that it all worked out.

Regards,

Bob -

Yeah, looks very good. Keep us posted.

-

Dear Fred,

You can also buy off-the-shelf plastic balls:

http://plasticballs.com/delrin.htm

For my development model I would drill and tap the plastic ball to take a wire-thread insert (http://www.emhart.com/products/helicoil.asp). The insert would increase the durability of the thread, making stripping out less likely.

A production model might use moulded-in fittings (for example http://www.anchorinserts.co.uk/)

A one piece moulding (ball and attached arm) might also be possible.

Regards,

Bob -

Bob,

Thanks so much for sharing the leads!

Since this "system" is open source I hope that you and others will be interested in trying your own variations on the theme. One of the cool things about the system is that it is scalable. When I first got interested in TINs I thought they would make a great building toy and still do. In this entry to the Buckminster Fuller Challenge I tried to make the argument that a TIN building system (or toy) would help people think outside the box. (BTW, there are a lot of interesting design proposals on the BFC pages.)

I'm focusing now on a version that could be implemented with inexpensive materials by local craftspeople, but that is just one of many possible paths to explore. If anyone is interested I would like to consider working with a few people to develop a proposal for the 2009 International Development Design Summit.

Fred

-

what **production material **are you thinking of, fbartels ?

-

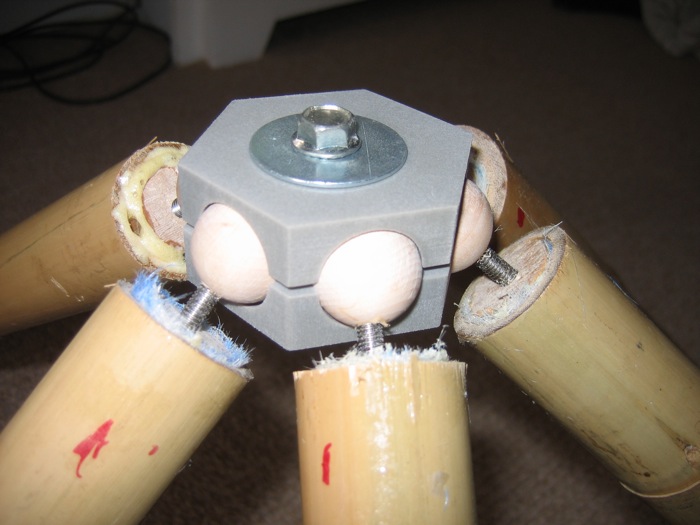

First test of the part. The photos pretty much tell the story. No surprises in terms of the pieces going together as designed.

I didn't put much stress on the hub because I definitely don't want to break the prototype. When (and if) I'm able to reproduce the part in a production material then I'll really tighten up the bolt and stress test it.

-

@juanv.soler said:

what **production material **are you thinking of, fbartels ?

Juan,

As I noted in an earlier post I want to try using Ductal as its cost is within my limited research budget and it just might work really well.

Fred

-

cant it be softened the prototype with Ductal ?

i did not know it. thanks for the link.

and a great work of investigation you are making.

cheers -

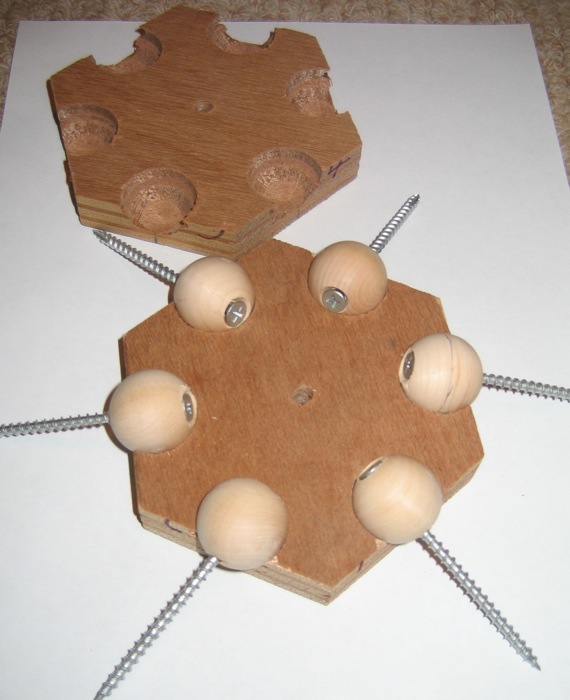

After letting this lie fallow for quite a while I had an idea to try a slightly different approach. Using a round router bit I've been able to make half-spherical holes in plywood hexagons. With the help of the wood shop teacher at my school I've come up with a jig idea that should allow me to make these hubs reasonably easily and quickly. I'm going to try making a few over our upcoming March break. With those I'll see if I can't make a prototype curved roofing section using 2x2 deck rails as the spokes and half-inch plywood for the triangular faces.

-

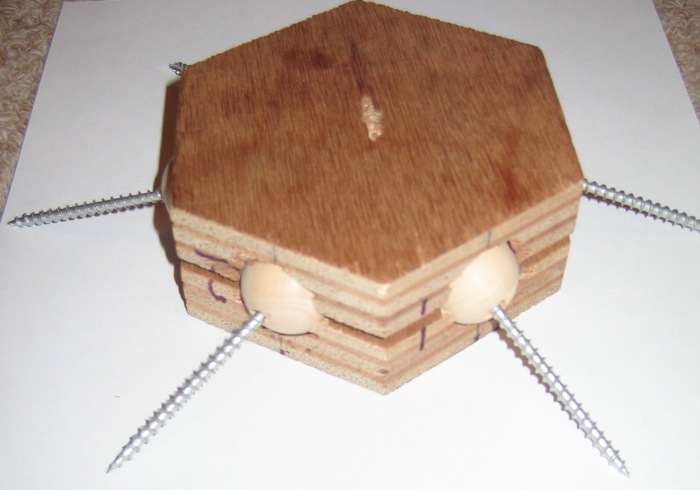

Just to bring the ongoing saga up to date.

I made six more of the hexagonal hubs out of plywood. (As an aside, let me state that it is a lot easier to build things in the virtual world of SketchUp than the real world of saws, drills and wood... and I have the bandaids to prove it.) The jig I built to assist with creating the hubs helped but I'm not able to cut the hexagons to the tolerances really needed to make the jig work well.

Anyway, I put everything together yesterday, glued it up and tightened up the bolts. I am quite pleased with the results. I now have a prototype of a structurally solid wooden TIN. I can stand (all 200+ pounds of me) on the center hub and the TIN barely flexes. Next step is to cut triangles for the faces out of 1/2" plywood.

Advertisement