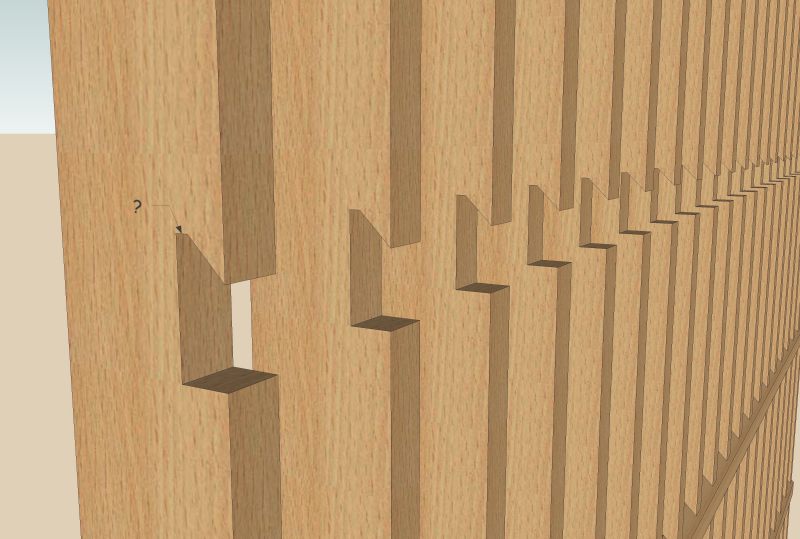

Simple wooden screen

-

Dear All,

I saw this simple wooden screen while visiting Kew Gardens. It had been placed in front of a large window and provided a very nice diffuse light. A number of water colours of plants and flowers were also hung from the screen.

Sometimes, simple is best.

Regards,

Bob

-

Thanks for sharing.

-

I like doing screens like that only I us a simple square cut notch in the uprights.

http://woodsshop.com/bbrbqrgb.htmI wonder how they cut those notches with that little shoulder left square at the top? Do any of you woodworkers have a guess? A bevel cut with the radial arm would get the top angle but how to cut that remaining square part?

-

Dear Joe,

I might have remembered the design wrongly, and so it is quite possible that the shoulder is not there. It is over a week ago that I saw the screen. You could, of course, water jet cut the recesses, but that might not be economical.

Watch the video on:

http://www.machinepartengineering.com/pages/waterjet-cutting-overview-149.htm

Regards,

Bob -

hey Bob, have you ever done (or had done) any wood cutting with a water jet? If so I have some questions about cutting 1.5" thick, clear western red cedar.

-

Dear Joe,

I have no experience of water jet cutting wood, but I have cut 1" aluminium plate and so I think that 1.5" of wood should not present a problem. There are some systems that will cut through 2 to 3"of steel. I have used laser cutting to cut 10 mm MDF, but the edges char (not surprisingly). For that application it didn't matter, and the price was right.

I have mostly used the technique for cutting shapes out of 1.5 mm stainless steel sheet. I used AutoCAD to array the shapes within a 1 m by 2 m rectangular boundary (sheet stock size), and then emailed the file to the the water-jet company to download into their control computer. It worked very well, it was very accurate and very economical on materials. If you look at Fig 2 on http://www.atm.ox.ac.uk/main/facilities/2point2_metre_facility/cool_6.html you will see some close-off panels on the floor. Those panels were shaped using water jet cutting, as was the bespoke cable tray.

Regards,

Bob -

Dear Joe,

I came across he following:

http://www.waterjets.org/waterjet_pictures_10.html

and

Regards,

Bob

Advertisement