MSPhysics...Gears

-

GEARS.skpim trying to figure out how a sequential transmission works so i started to build lego models (digitally)to help me under stand.

ive learned that the .dea lego provides are require a lot of fixing to work with physics so i decided ill just remodel from scratch...

now i use DHInvolute Gears plugin for 3d printing.

i have created 8T, 12T, 16T, 20T and 24T all 25.4P.

I grouped the teeth at where the convex shape starts.i have tried adding the hinge joint within the group of the gear and aswell as outside the group

each gear will spin on is own when all others ignored

if i turn off friction all gears will rotate but they ignore meshing

increased world scale to 40

im not sure whats going on and googing has not proved successful

attached file

-

-

@ecati said:

I made some fixes. You can see the changes I made by examining them.

good morning i have opened the file and all that i can see is an extra .3mm clearence between meshes of the pitch diameter, the center hub of each gear is grouped as well... and friction has been turned off.

i copied and pasted into my original and it still functions as it should (altho for some reason in mine it will fall away after running for a while )so i think i may be missing something...

i looked tthrough settings and i thinkk they are all default

please if you will kindly give me a clue as to where to look maby it will give me the ah ha moment i need lol -

@c0ryp1 said:

@ecati said:

I made some fixes. You can see the changes I made by examining them.

good morning i have opened the file and all that i can see is an extra .3mm clearence between meshes of the pitch diameter, the center hub of each gear is grouped as well... and friction has been turned off. he gear is only

i copied and pasted into my original and it still functions as it should (altho for some reason in mine it will fall away after running for a while )so i think i may be missing something...

i looked tthrough settings and i thinkk they are all default

please if you will kindly give me a clue as to where to look maby it will give me the ah ha moment i need lolok so i may have made some progress i started from scratch on a 8T Module1 gear.

grouped the tooth convex surfaces after the base circle.

set shape to convex hull.

group everything inside the base circle

set state to ignore

create component

copy and transform center distance and adjust for .08mm or ~.003" mesh clearance

add hinge and motor joints and link

set solver to 64passes

set worldscale to 100(40 was still allowing center points to drift 100 seems to have locked them in place)(might actually have to design at 1000% scale as the volume of the gear is only ~.2mm³ and it mentions 10mm³)

set motor damper to 5

turn off friction on gear bodiesim going to work on the 12, 16, 20, 24T models and see if i can get them to work as well.

-

-

@ecati said:

I add the explanation file.

thanks ecati i appreciate the help

gears are working as expected now.

I didnt want to make a new post for this so perhaps you can help with my rotary cam system.

upper wheel @ 20° rotates back and forth which pushes the cam. this function works fine.

when i add a motor joint to the rotor it breaks the model and no longer rides back and forth on the slider.

physics.skp

^either cam/rotor is ignored while testing -

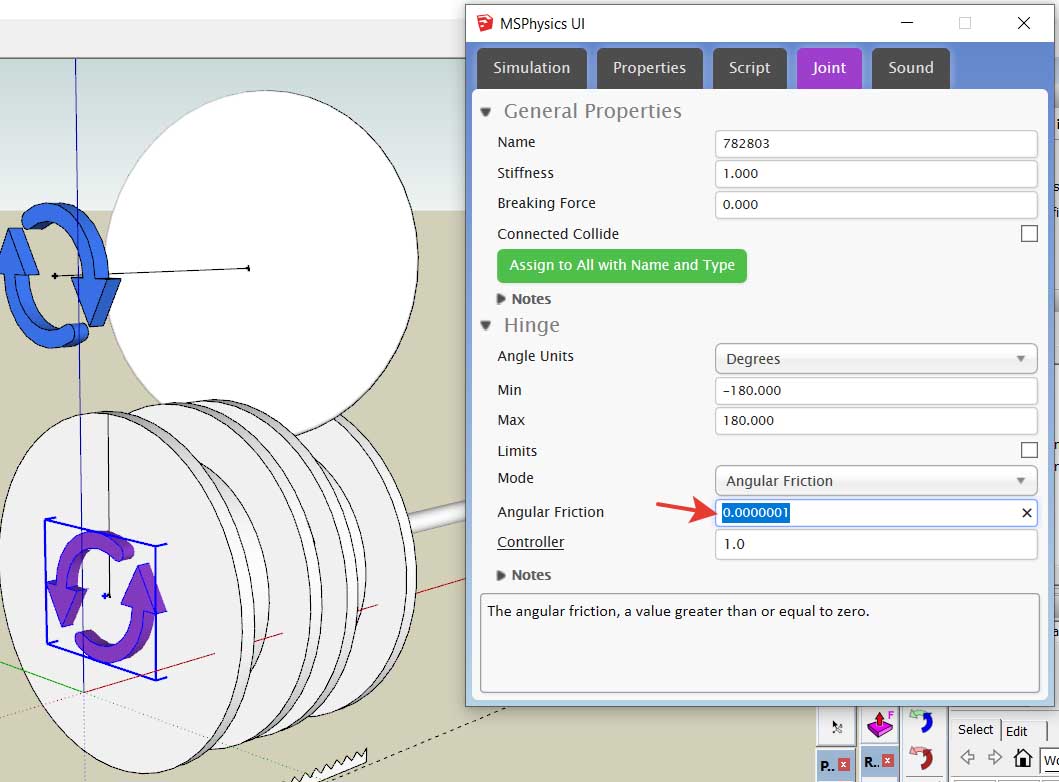

There are centering errors, be careful. I fixed it. Other edits can be seen in the file. Make the settings shown in the pictures.

-

@ecati said:

There are centering errors, be careful. I fixed it. Other edits can be seen in the file. Make the settings shown in the pictures.

man you are great with this stuff thanks...ill try using lines to make sure my parts are all centered and adjust settings to see if it works in mine

-

@ecati said:

There are centering errors, be careful. I fixed it. Other edits can be seen in the file. Make the settings shown in the pictures.

centering + settings got that one to work

dont understand how my points messed up tho but i activate the auto reset as i think i may have forgot to undo it myself.

dont understand how my points messed up tho but i activate the auto reset as i think i may have forgot to undo it myself.also do you have a trick to help you determine when a joint should be in a body vs outside of the body?

now i just need to find some documentation on the friction settings as ten millionths of a unit seems like it shouldn't effect anything

-

We make this adjustment so that the second wheel stops. If you set "Angular Friction = 0", you will see that the wheel continues to spin.

"MSPhysics_v1.0.3" does not work properly yet. Author Anton_S is working on the new version. The new version has been released yet.

For more information see here. https://sketchucation.com/forums/viewtopic.php?f=323&t=56852&start=840

Advertisement