Sketchup for Machine Design and Interaction with Data Base

-

Hi all,

I am a part of The Aagard Grouphttp://www.aagard.com. We design, engineer, and manufacture robotic packaging equipment. Currently we are in the process of changing our CAD/CAM software.The main purpose of this post is to find out if there is anyone in the world doing what we are trying to do. And to find out if what we are trying to do is feasible.

The broad overview of what we want to accomplish is this:

• Our primary use of sketchup is to view and edit data• All of our data will be stored in data tables

• We will have a data base application which will allow us to sort our data conveniently, perform dynamic searches, calculate lead times, assign time to projects, ect…

• Behind the scenes the same interface will be interactive with sketchup, so that as we view and edit data in sketchup it is instantly changing in our tables and vice versa. We want sketchup and our data tables to be interactive to the point where the data table interface can supply information based on what the user is doing in sketchup.

• Since the majority of parts are very similar and many of the same machining process’s are repeated over and over again we are creating interface plug-ins for sketchup to:

-

Draw rectangular or round bar stock

-

Draw and place; holes, tapped holes, counter-bores, counter-sinks, and slots

• The data created for these parts in the data tables will then be handed off to code that generates the proper CNC code for our mills to machine the parts

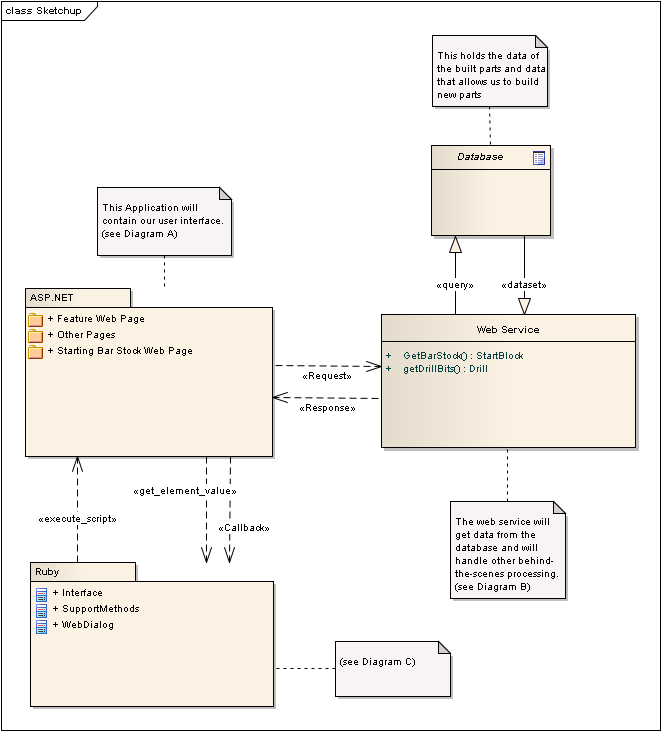

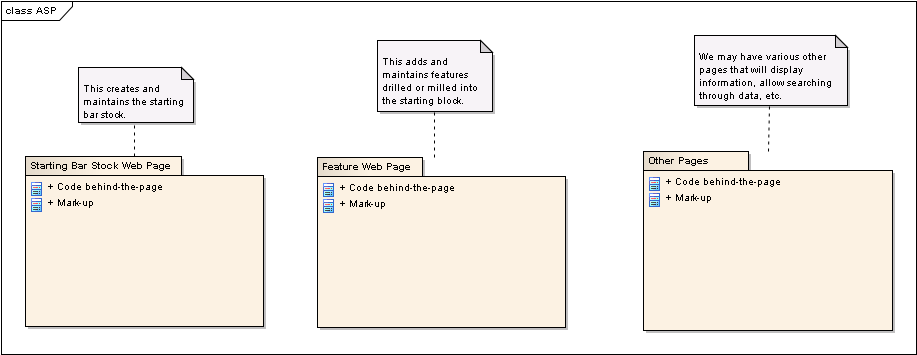

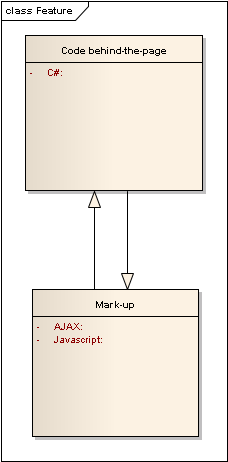

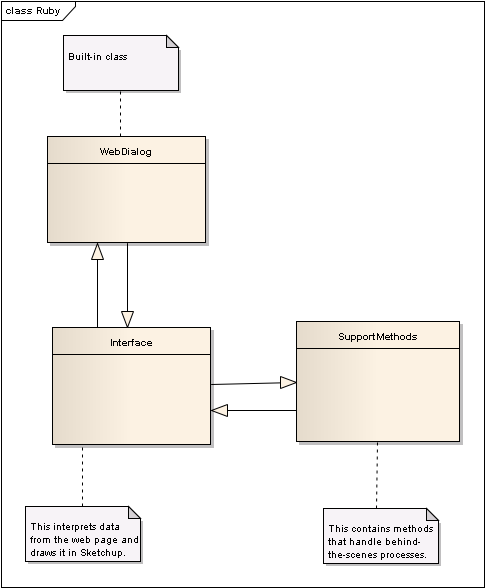

Here are some detailed diagrams outlining our code structure:

I would be excited to learn if anyone is doing something similar with sketchup. Also, if you notice anything in our code structure or our thinkology that is not feasable or is ineffecient please let me know

Thanks

Ross Feiler -

-

We've done some testing with the model size issue. our machines can have up to 2,000 parts in them so it was a concern. But sketchup did not have a hard time with 2,000 parts in our tests. I think its mostly because the parts we draw are very simply with few faces.

-

I can't even begin to answer a lot of your database questions as I don't do a lot of programming. However, I do understand components. We manufacture custom HVAC ducting and piping, so while the component list is small, the need for the list work is still there. So, I made a dynamic component of a flange, with a bolt pattern.

See my attached sketchup file using this dynamic component. Under file, click generate report. Using the native tools with sketchup, this seems at the very least feasible to me. With the report generator, I am able to harvest the information I need with the ItemCode section, which would let me identify my large components. The small component information can be used to build my device with the proper CNC machining equipment. Although it has X,Y,Z information that is relative to the coordinates of the minor components, it would require simple vector addition to get the precise location of each hole in the model, and feed that to the CNC.

Working in reverse is a bit more complicated, but dynamic components would make working in reverse possible (an advantage). You could edit the data in your tables, use a script to redraw the dynamic component with the updated values, and viola! It would be updated. X, Y, Z and LenX, LenY, LenZ values would be recalculated and ready for the CNC. This does take some time however, as well designed dynamic components would take time.

Unfortunately, this will not be updated instantaneously. There would have to be a request for redraw, or a request to save the generated report, so these scripts could not be used if you wanted instantaneous information. Still, it would beat working with the sometimes buggy "observers" of ruby. And the report generator is actually a ruby script (so you could make it anew). The only issue I would see then is finding someway of having your ASP net "ping" sketchup to regenerate the report and redraw the model.

Advertisement